A kind of preparation method of aluminum-magnesium-nickel-manganese spherical cobalt tetroxide

A technology of tricobalt tetroxide and magnesium-nickel-manganese, which is applied in the direction of structural parts, electrical components, battery electrodes, etc., can solve the problem that the specific capacity and cycle retention rate of the battery cannot be kept in balance, the precipitation of doping elements is incomplete, and it is difficult to ensure the electrical performance of the battery To achieve excellent test results, avoid aggregation, and good sphericity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] 1. Prepare the solution: take the cobalt sulfate solution produced in the extraction process, dilute it to a concentration of 1.7mol / L with hot pure water; weigh 10g of the doping element aluminum sulfate octadecahydrate, heptahydrate Add 2g of magnesium sulfate, 0.8g of nickel sulfate hexahydrate, and 1.03g of manganese sulfate monohydrate into the prepared cobalt liquid, then add complexing agent EDTA into the cobalt liquid, and mix well, the molar ratio of complexing agent EDTA to Co ions 0.19%; prepare 9mol / L sodium hydroxide solution for subsequent use;

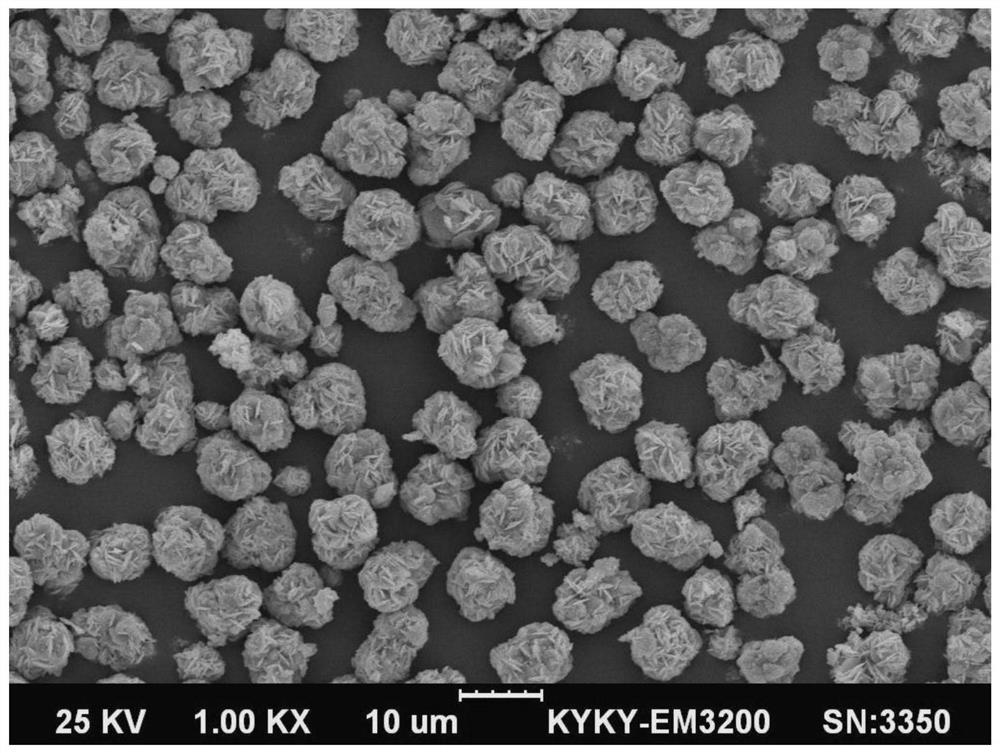

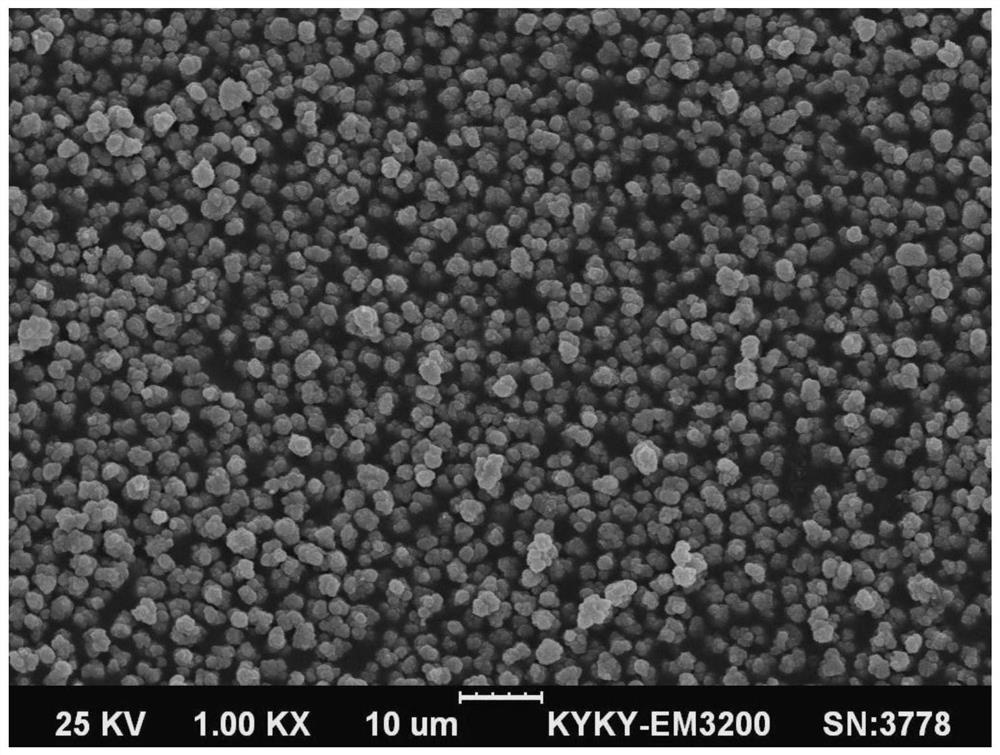

[0026] 2. Wet synthesis: add hot pure water to the reaction kettle in advance, adjust the pH to 11.5, then pump the cobalt liquid, sodium hydroxide solution and compressed air prepared in step 1 into the reaction kettle at the same time, and synthesize at a temperature of 78°C and The synthesis reaction is carried out at a stirring speed of 360r / min, and 100L / h of compressed air is introduced, and the pH of the sy...

Embodiment 2

[0030] 1. Prepare the solution: take the cobalt sulfate solution produced in the extraction process and dilute it to a concentration of 2mol / L with hot pure water; weigh 11.8g of the doping element aluminum sulfate octadecahydrate and heptahydrate for each liter of cobalt solution Add 2.36g of magnesium sulfate, 0.89g of nickel sulfate hexahydrate, and 1.2g of manganese sulfate monohydrate into the prepared cobalt liquid, then add complexing agent EDTA into the cobalt liquid, and mix well, the mole of complexing agent EDTA and Co ions The ratio is 0.3%; prepare 5mol / L sodium hydroxide solution for subsequent use;

[0031]2. Wet synthesis: add hot pure water to the reaction kettle in advance, adjust the pH to 11.5, then pump the cobalt liquid, sodium hydroxide solution and compressed air prepared in step 1 into the reaction kettle at the same time, and synthesize at a synthesis temperature of 78°C Carry out the synthesis reaction, the stirring speed is gradually reduced from 36...

Embodiment 3

[0035] 1. Prepare the solution: take the cobalt sulfate solution produced in the extraction process, dilute it to a concentration of 1.7mol / L with hot pure water; weigh 12.5g of doping element aluminum sulfate octadecahydrate, seven Add 1.9g of magnesium sulfate water, 0.75g of nickel sulfate hexahydrate, and 1g of manganese sulfate monohydrate into the prepared cobalt liquid, then add complexing agent EDTA into the cobalt liquid, mix well, and complex The molar ratio of agent EDTA and Co ion is 0.15%; Prepare 12mol / L sodium hydroxide solution for subsequent use;

[0036] 2. Wet synthesis: add hot pure water to the reaction kettle in advance, adjust the pH to 11.5, then pump the cobalt liquid, sodium hydroxide solution and compressed air prepared in step 1 into the reaction kettle at the same time, at a synthesis temperature of 62°C Carry out the synthesis reaction, the stirring speed is 380r / min, and the compressed air is 90L / h, and the pH of the synthesis process is controll...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com