Optimal cut-set virtual disassembly sequence planning method for large-scale and complex equipment

A sequence planning and complex technology, applied in design optimization/simulation, etc., can solve problems such as poor versatility, difficulty in porting to other systems, and insufficient knowledge base matching ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

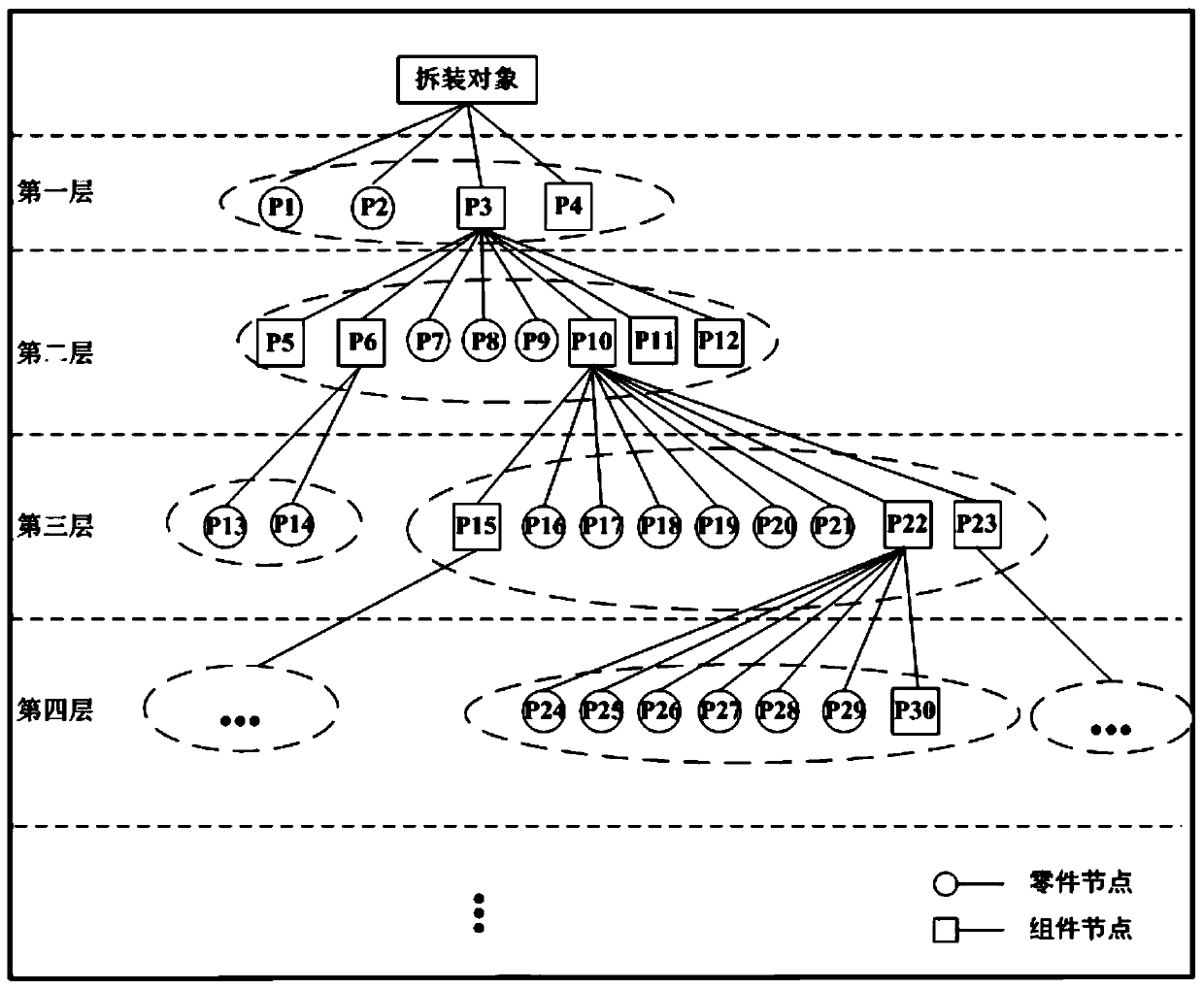

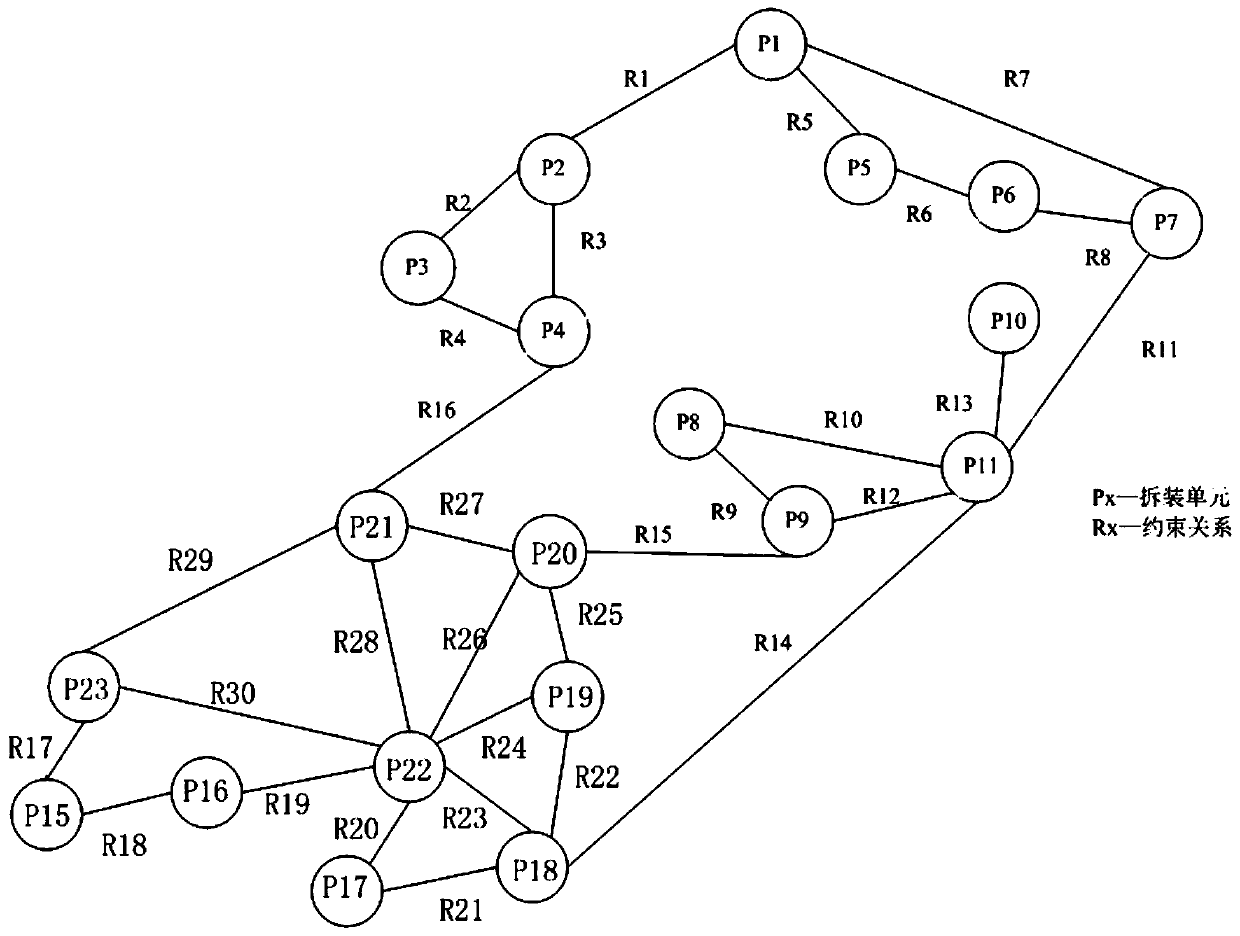

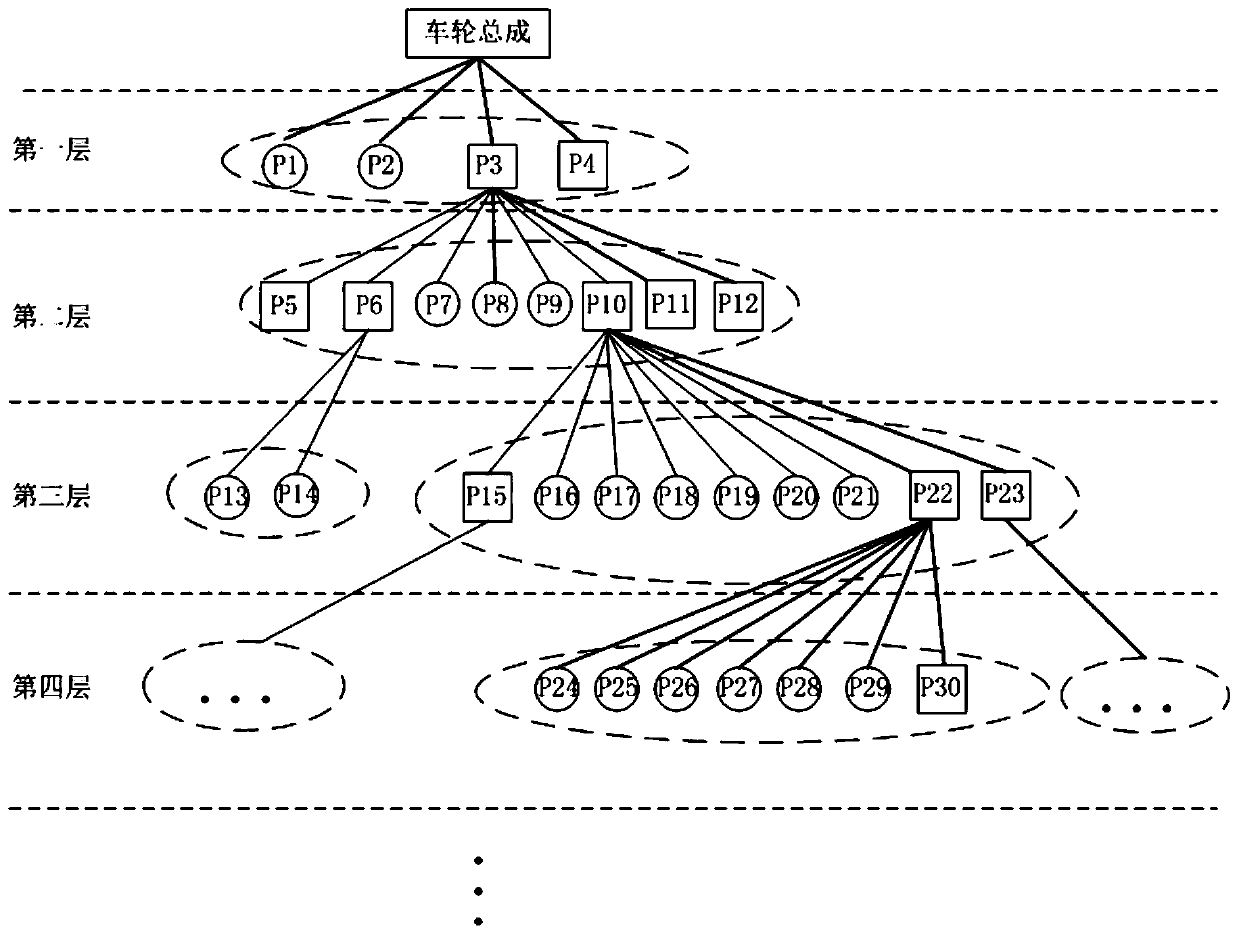

[0045] like figure 1 , figure 2 and Figure 8 As shown, the method for planning the virtual disassembly and assembly sequence of large-scale and complex equipment hierarchically associated optimal cut sets of the present invention includes the following steps:

[0046] Step 1. Construct a multi-level relationship disassembly tree model of large and complex equipment disassembly objects: disassemble and disassemble the large and complex equipment in layers, so that the disassembly objects of large and complex equipment are disassembly objects of multi-level structure. The disassembly and assembly objects of the multi-level structure are represented by a multi-level relationship disassembly tree model, and the multi-level relationship disassembly tree model of large and complex equipment disassembly objects is constructed with the disassembly object as the root node of the tree, wherein the multi-level relationship disassembly The leaf nodes of the tree model are non-decompos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com