Aluminum foil sealing performance detection device of daily chemical product bottle and detection method

A technology for tightness detection and bottle tasting, which is applied in the direction of using liquid/vacuum degree for liquid tightness measurement, and by measuring the increase and deceleration rate of fluid, etc., can solve the problems of high labor intensity and low work efficiency of workers, and achieve work efficiency. High, easy to operate, reduce labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

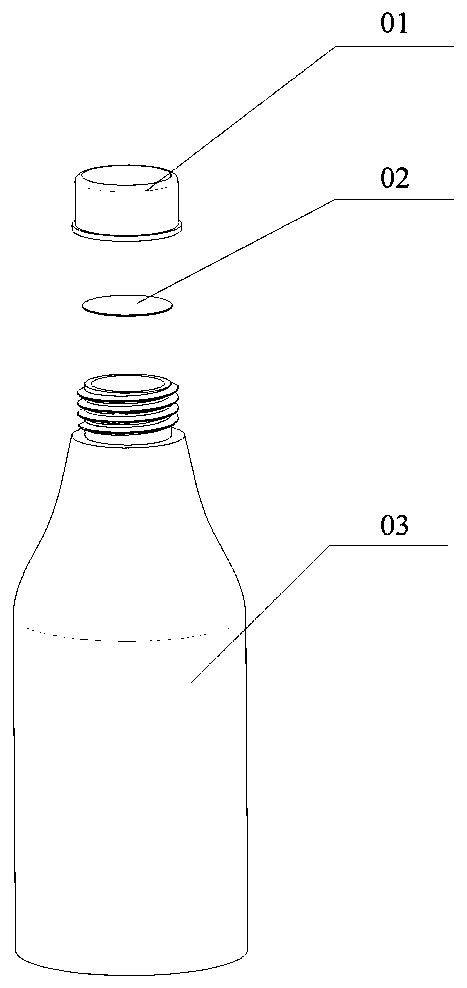

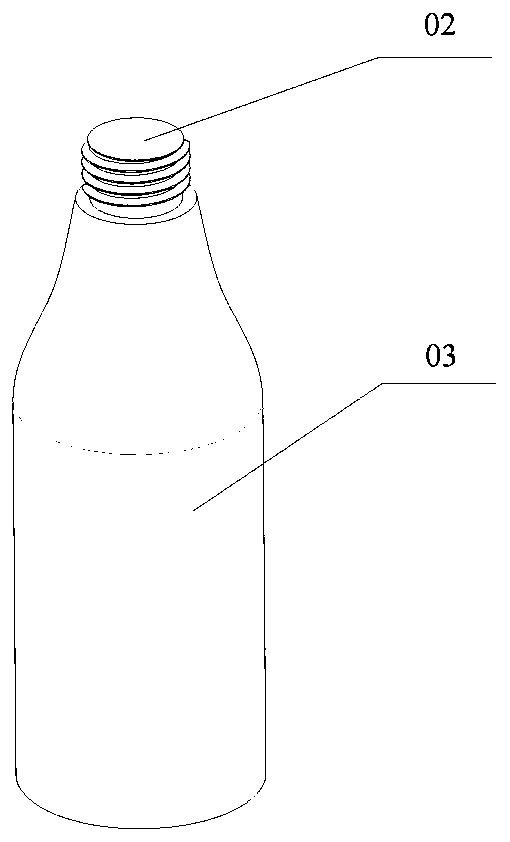

[0029] In this example, figure 1 It is the state of daily chemical bottle before canning and aluminum foil sealing, including bottle cap 01, aluminum foil gasket 02 and bottle body 03. figure 2 It is a daily chemical bottle after production of aluminum foil sealing. image 3 It is a schematic diagram of the aluminum foil sealing of the daily chemical bottle after the bottle cap is unscrewed.

[0030] Such as Figure 4 As shown, a daily chemical bottle aluminum foil airtightness detection device includes a linear module driving mechanism 1, a platen 2, and a pressure measuring mechanism 3. The platen 2 is used for fixed installation of the linear module driving mechanism 1 and the pressure measuring mechanism 3 .

[0031] The linear module driving mechanism 1 is installed on the platen 2, and is used to apply a certain amount of extrusion in the radial direction of the circumference of the daily chemical bottle that has completed the production of aluminum foil sealing; the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com