Automatic control compressed air drainage device

A compressed air and water-repelling technology, applied in steam traps, mechanical equipment, etc., can solve problems such as inability to perform automatic water-repelling control, failure of floats, and high requirements for media

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

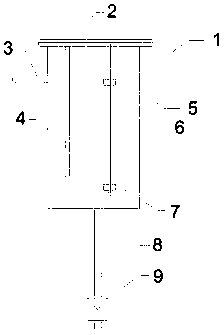

[0026] Embodiment 1: as figure 1 , 2 , shown in 6, an automatic control compressed air drainage device, comprising:

[0027] The tank body 1 connected with the compressed air outlet, the upper part of the tank body 1 is provided with an air inlet, and the air inlet is connected with an air inlet pipe 3 suitable for its diameter, so as to realize the connection with the compressed air outlet, so The top of the tank body 1 is open, the circumference is provided with a flange, the bottom of the tank body 1 is provided with a drain port, and the inside of the tank body 1 is provided with a baffle plate 4, which separates the tank body 1 into left and right parts. The upper part of the baffle 4 is opened to connect the left and right sides of the baffle 4 to exhaust gas. There is a gap between the bottom of the baffle 4 and the bottom of the tank body 1. The gap is 20 mm. The left and right sides of the baffle 4 are connected to form a U-shaped pipe to allow condensed water to pas...

Embodiment 2

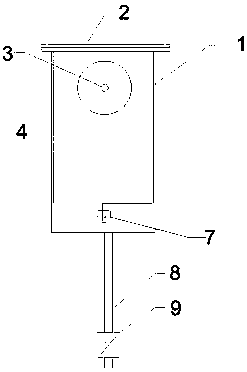

[0033] Embodiment 2: as image 3 , 4 , shown in 6, an automatic control compressed air drainage device, comprising:

[0034]The tank body 1 connected with the compressed air outlet, the upper part of the tank body 1 is provided with an air inlet, and the air inlet is connected with an air inlet pipe 3 suitable for its diameter, so as to realize the connection with the compressed air outlet, so The top of the tank body 1 is open, the circumference is provided with a flange, the bottom of the tank body 1 is provided with a drain port, and the inside of the tank body 1 is provided with a baffle plate 4, which separates the tank body 1 into left and right parts. The upper part of the baffle 4 is opened to connect the left and right sides of the baffle 4 to exhaust gas. There is a gap between the bottom of the baffle 4 and the bottom of the tank body 1. The gap is 20 mm. The left and right sides of the baffle 4 are connected to form a U-shaped pipe to allow condensed water to pass...

Embodiment 3

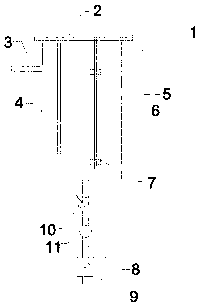

[0040] Embodiment 3: as figure 1 , 5 , shown in 6, an automatic control compressed air drainage device, comprising:

[0041] The tank body 1 connected with the compressed air outlet, the upper part of the tank body 1 is provided with an air inlet, and the air inlet is connected with an air inlet pipe 3 suitable for its diameter, so as to realize the connection with the compressed air outlet, so The top of the tank body 1 is open, the circumference is provided with a flange, the bottom of the tank body 1 is provided with a drain port, and the inside of the tank body 1 is provided with a baffle plate 4, which separates the tank body 1 into left and right parts. 4 The upper part is opened to connect the left and right sides of the baffle 4 to exhaust gas, and the lower part is provided with a filter hole 12. The left and right sides of the baffle 4 are connected to form a U-shaped pipe to allow condensed water to pass through and ensure that the water levels on both sides are co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com