Air-cooled underground continuous wall condenser pipe device and construction method

An underground diaphragm wall and condensation pipe technology, which is applied in sheet pile walls, foundation structure engineering, construction, etc., can solve the problems of wall concrete strength not meeting the design requirements, temperature stress cracks, etc., and achieves high practical value and simple method , The effect of reducing engineering water use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

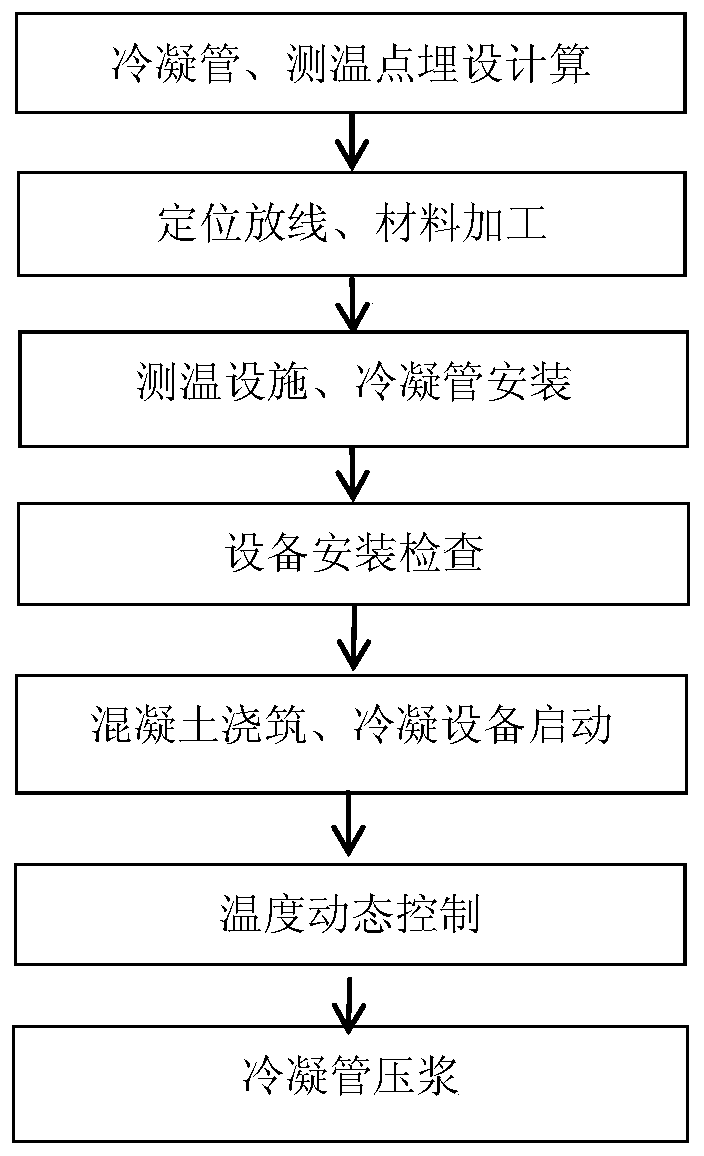

[0033] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described below in conjunction with the accompanying drawings.

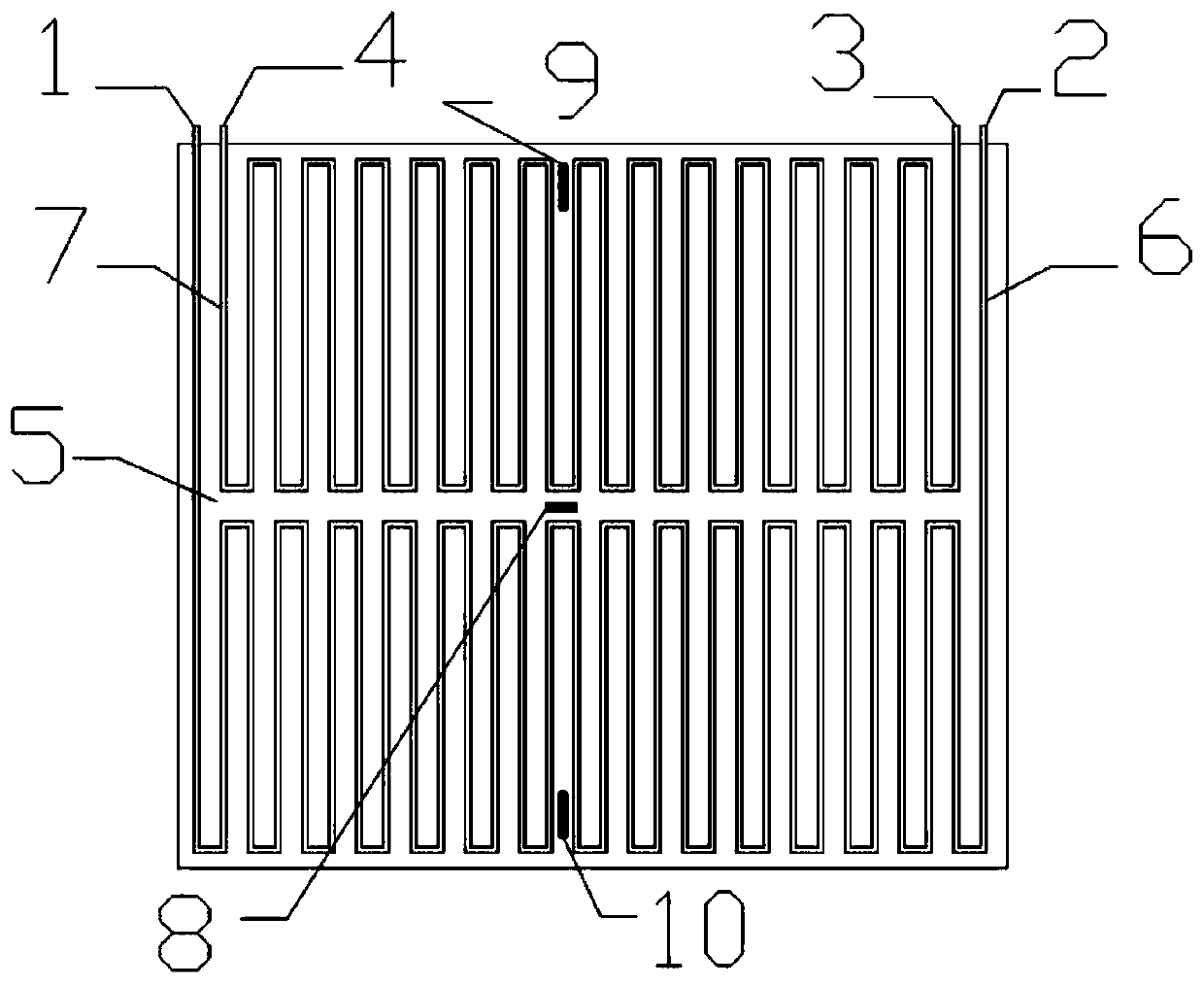

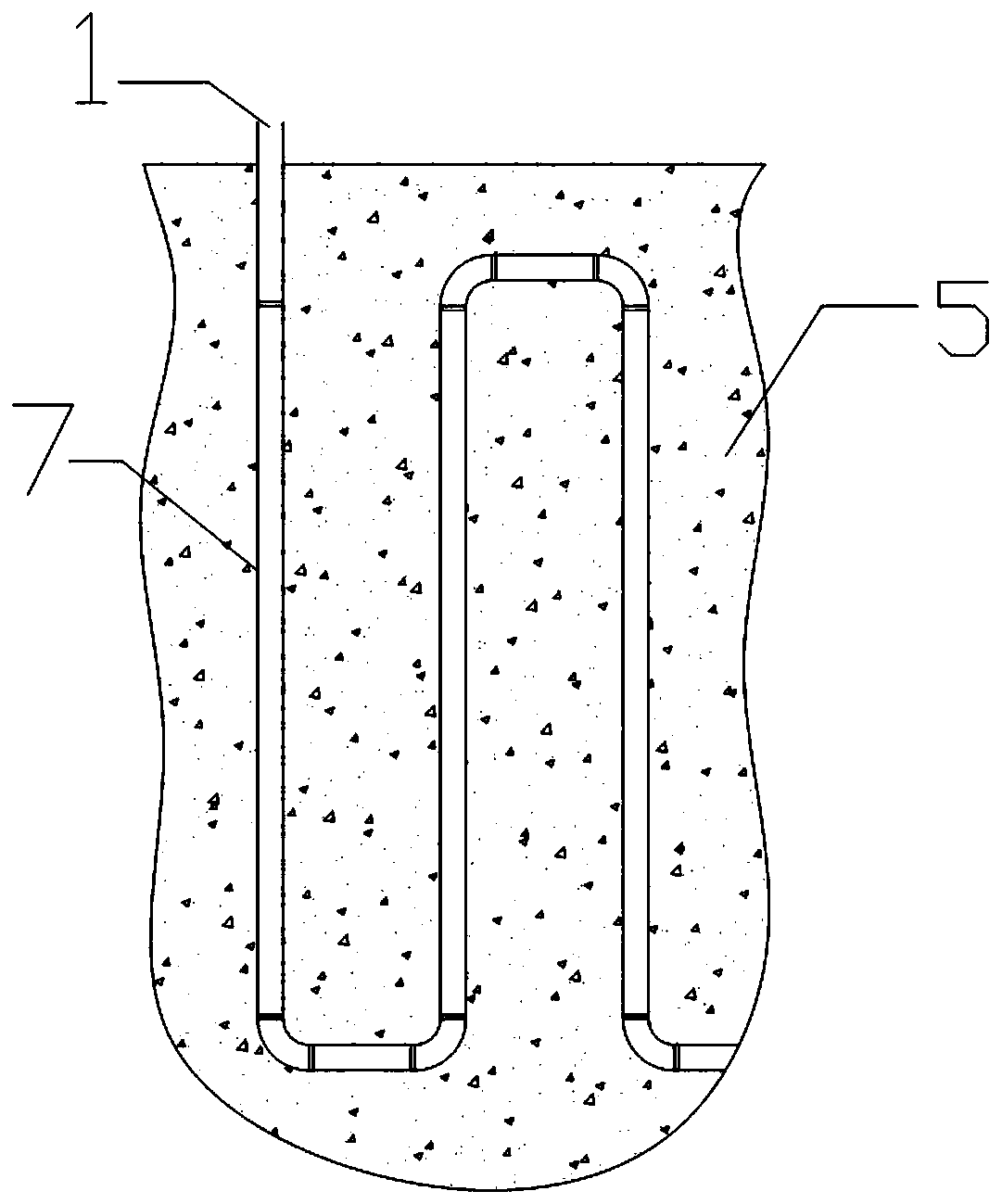

[0034] refer to Figure 1 to Figure 6 , an air-cooled underground diaphragm wall condensing tube device, comprising a first condensing tube buried in the upper layer of the underground diaphragm wall; a second condensing tube buried in the lower layer of the underground diaphragm wall; first, second, and second tubes for detecting the temperature of concrete The third temperature sensor; two sets of high-power industrial fans and water-cooled air conditioners: the head and tail ends of the condensation pipe assembly are respectively provided with an air inlet and an air outlet; the air inlet is connected to the water-cooled air conditioner; the air outlet is connected to the exhaust fan.

[0035] Further, the first temperature sensor is used to collect temperature change da...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com