Fabric electrode substrate and application and preparation method thereof

A fabric electrode and base material technology, applied in the direction of plant fibers, textiles, papermaking, fiber types, etc., can solve the problems of poor cycle stability and damage, and achieve low cost, short reaction time, and simple preparation process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

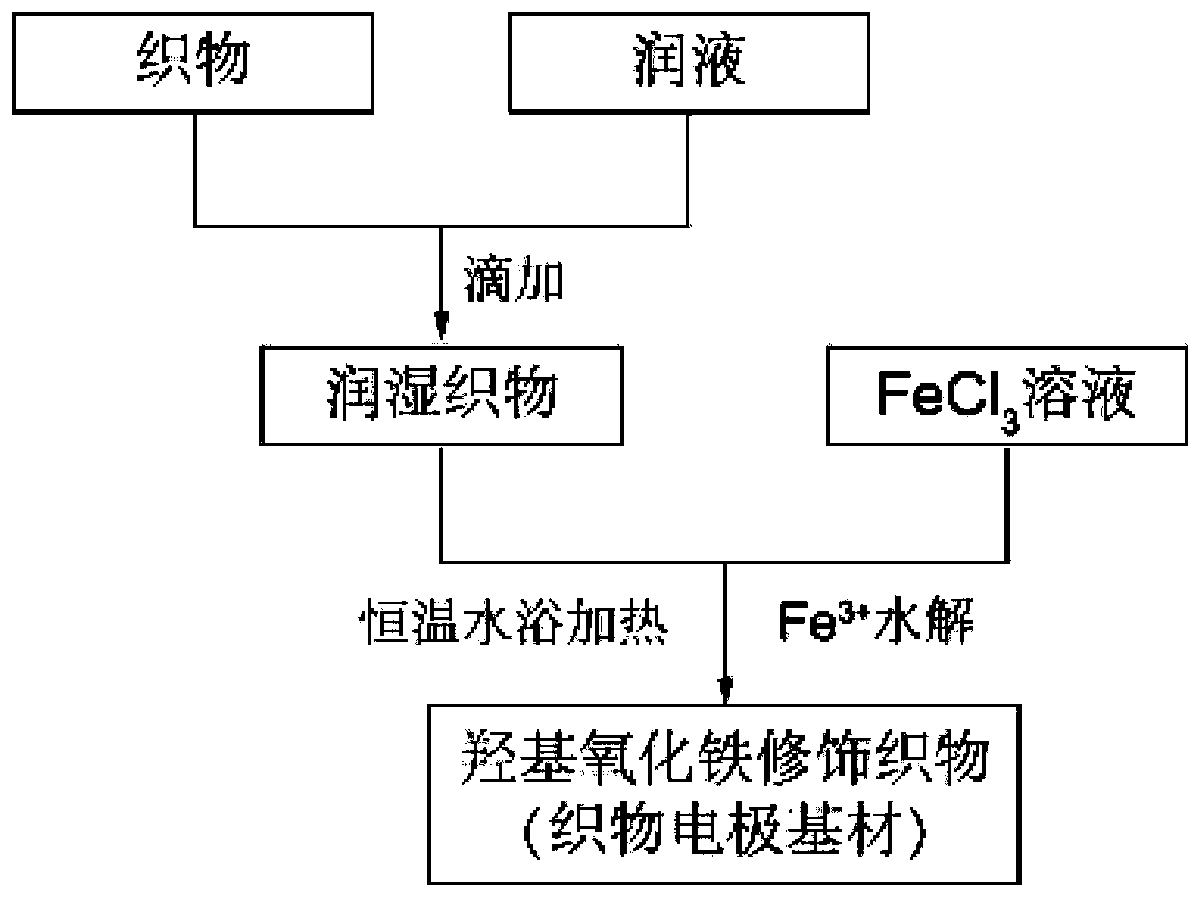

[0020] The preparation method of fabric electrode substrate comprises the following steps, as figure 1 :

[0021] (1) Take a 5cm×5cm cotton fabric, drop ethanol onto the surface of the cotton fabric, place the wetted fabric in FeCl with a mass concentration of 10g / L 3 In the aqueous solution, soak for 40min and stir at a stirring rate of 180r / min. The surface of the fabric fiber wetted by ethanol is rich in hydroxyl groups, which can attract more positively charged ions. Soak the wet fabric in FeCl 3 The aqueous solution can make the fabric fully absorb Fe 3+ , to prepare for the subsequent in-situ deposition of FeOOH;

[0022] (2) Stir the mixture of step (1) in a constant temperature water bath in a water bath at 80°C, the stirring rate is 100r / min, and the stirring time is 2 hours, Fe 3+ A hydrolysis reaction occurs to form iron oxyhydroxide and deposits on the surface of the fabric;

[0023] (3) After the product obtained in step (2) is cooled, it is cleaned and dried ...

Embodiment 2

[0026] The preparation method of fabric electrode substrate comprises the following steps:

[0027] (1) Take a 5cm×5cm polyester fabric, drop acetone onto the surface of the polyester fabric, place the wetted fabric in FeCl with a mass concentration of 160g / L 3 In the aqueous solution, soak for 10min and stir at a stirring rate of 200r / min. The surface of the fabric fiber wetted by acetone is rich in carbonyl groups, which can attract more positively charged ions. Soak the wet fabric in FeCl 3 The aqueous solution can make the fabric fully absorb Fe 3+ , to prepare for the subsequent in-situ deposition of FeOOH;

[0028] (2) Stir the mixture of step (1) in a constant temperature water bath in a 100°C water bath, the stirring rate is 400r / min, and the stirring time is 1 hour, Fe 3+ A hydrolysis reaction occurs to form iron oxyhydroxide and deposits on the surface of the fabric;

[0029] (3) After the product obtained in step (2) is cooled, it is cleaned and dried to obtain a...

Embodiment 3

[0032] The preparation method of fabric electrode substrate comprises the following steps:

[0033] (1) Take a 5cm×5cm cotton fabric that has been pretreated by soaking in 2mol / L sodium hydroxide solution for 15 minutes, add ethanol dropwise to the surface of the cotton fabric pretreated by sodium hydroxide solution, and place the wetted fabric on FeCl with a mass concentration of 85g / L 3 In the aqueous solution, soak for 25min and stir at a stirring rate of 190r / min. The surface of the fabric fiber wetted by ethanol is rich in hydroxyl groups, which can attract more positively charged ions. Soak the wet fabric in FeCl 3 The aqueous solution can make the fabric fully absorb Fe 3+ , to prepare for the subsequent in-situ deposition of FeOOH;

[0034] (2) Stir the mixture of step (1) in a constant temperature water bath in a 90°C water bath, the stirring rate is 250r / min, and the stirring time is 1.5 hours, Fe 3+ A hydrolysis reaction occurs to form iron oxyhydroxide and depos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com