A kind of automatic temperature regulation method of Czochralski silicon single crystal

A technology of Czochralski silicon and automatic adjustment, which is applied in the direction of single crystal growth, single crystal growth, chemical instruments and methods, etc., and can solve problems such as long distance, low measurement accuracy, and inconsistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

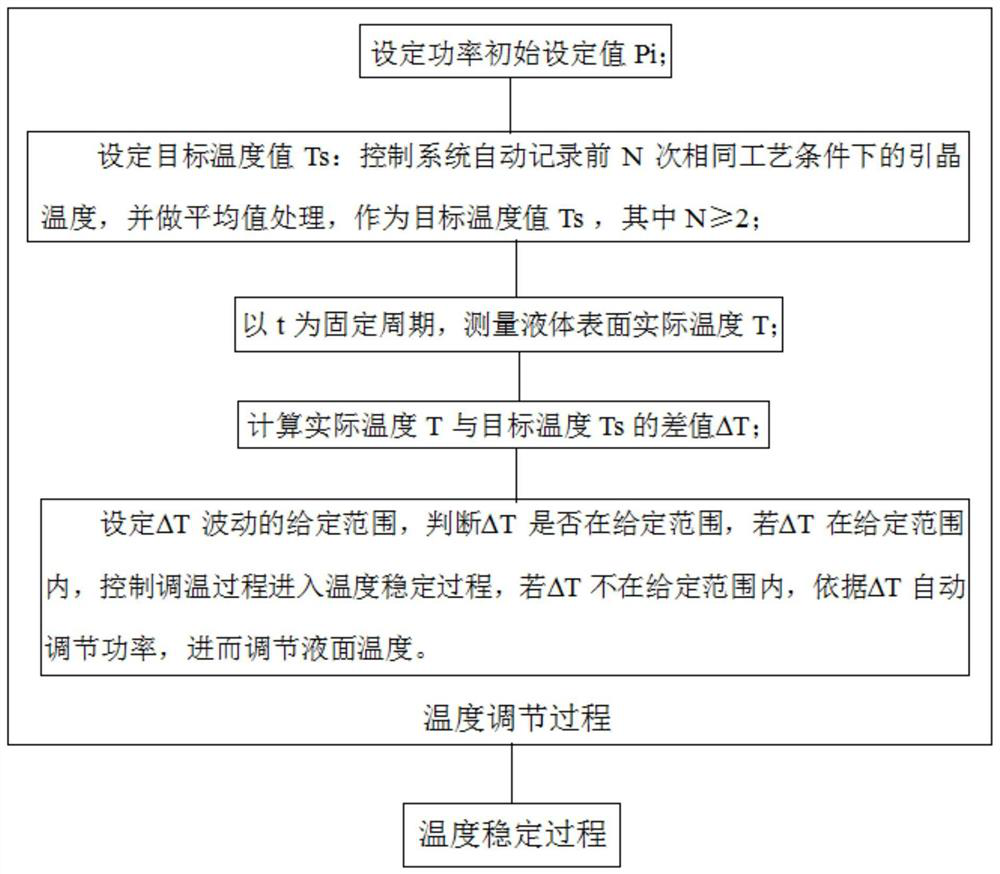

[0046] combine figure 1 , the automatic temperature adjustment method of the Czochralski silicon single crystal in this embodiment includes a temperature adjustment process and a temperature stabilization process, specifically including the following steps:

[0047] 1. Set the initial power setting value Pi in the control system. In this embodiment, Pi is 55.0kw;

[0048] Set the target temperature value Ts: the control system automatically records the seeding temperature of the previous N times, N≥5, under the same process conditions, and performs average value processing as the target temperature value Ts;

[0049] The same process conditions refer to the use of the same heater, insulation components, heat exchange components and other related components that affect the temperature in the single crystal furnace.

[0050] 2. Taking t as the fixed cycle time, measure the actual temperature T of the liquid surface of the silicon melt; wherein, the range of t can be 100-3000s. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com