Coating device

A technology of coating device and coating chamber, which is applied in sputtering coating, ion implantation coating, gaseous chemical coating, etc., can solve the problems of low degree of automation, unsafety, and inconvenient cleaning operation of the film layer, and achieve easy operation , the effect of improving the degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

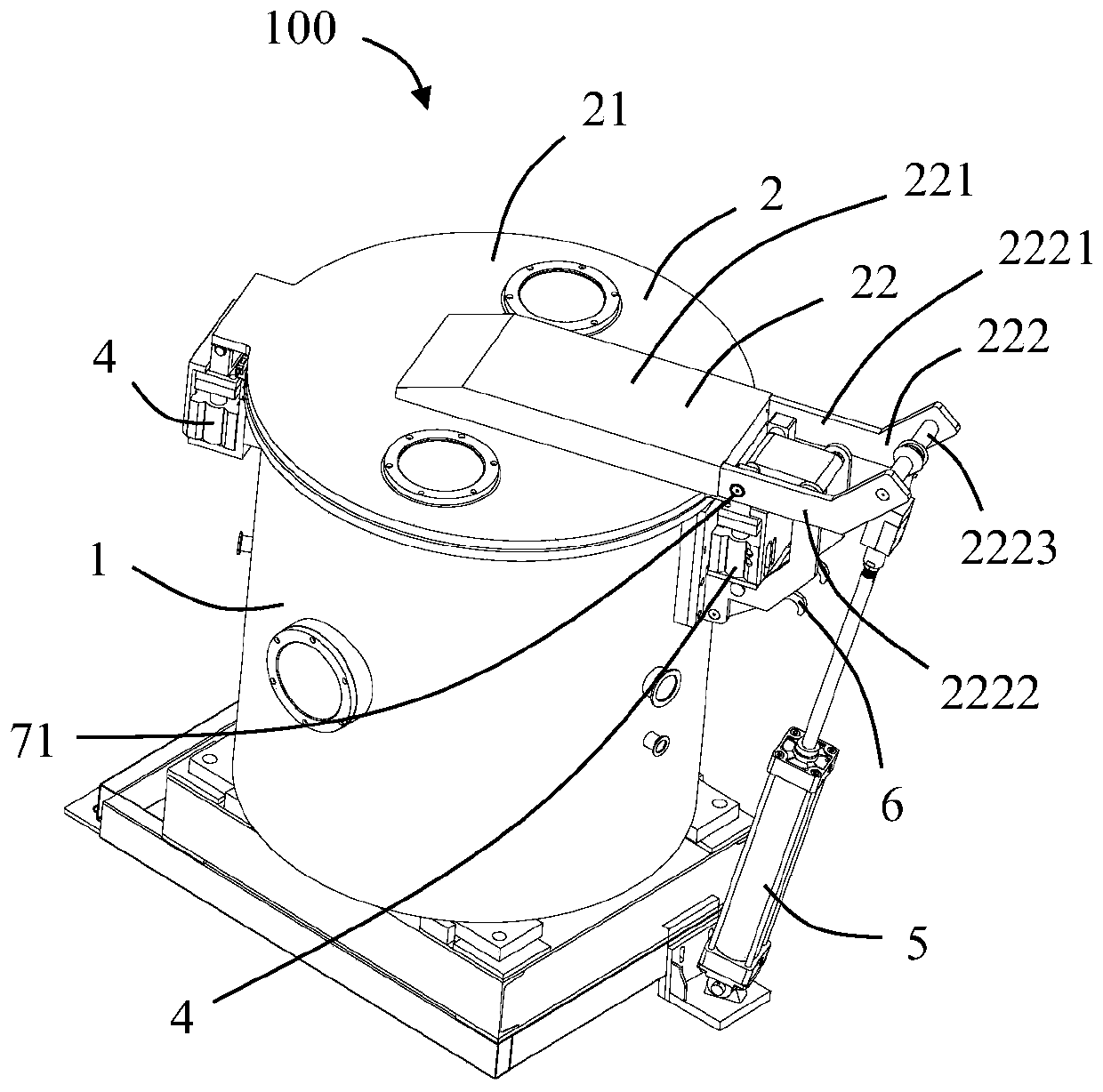

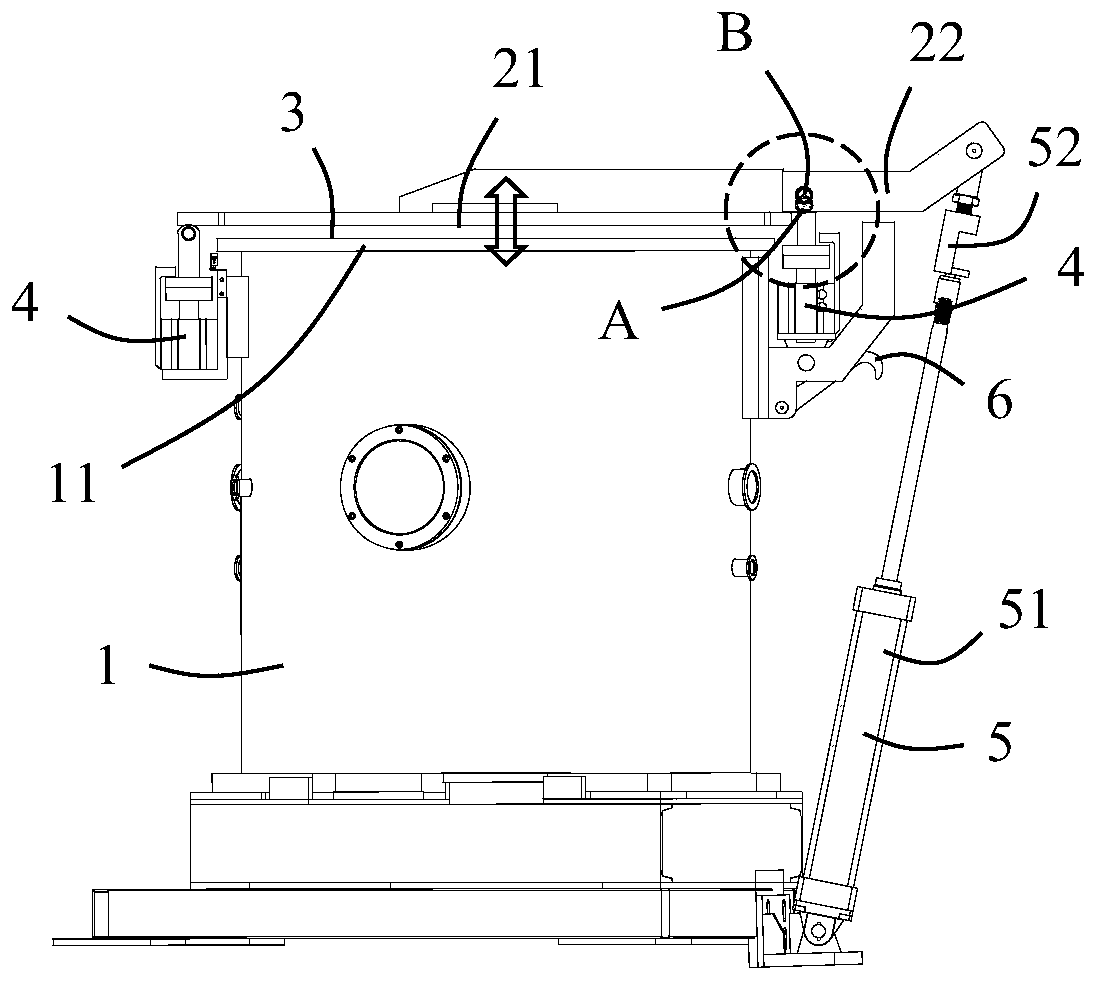

[0025] Please refer to Figure 1 to Figure 8 As shown, the present invention discloses a coating device 100, which can be applied to chemical vapor deposition (hereinafter referred to as CVD) coating equipment, physical vapor deposition (hereinafter referred to as PVD) coating equipment or other vacuum coating equipment.

[0026] Please refer to figure 1 , figure 2 and Image 6 As shown, the coating device 100 includes a main body 1 having a coating chamber 10 , a cover assembly 2 installed on the main body 1 , and a seal between the main body 1 and the cover assembly 2 Element 3, at least two sets of jacking mechanisms 4 for jacking up the cover plate assembly 2, a rotation drive mechanism 5 for driving the cover plate assembly 2 to rotate after the cover plate assembly 2 is lifted, and A safety mechanism 6 for fixing the cover plate assembly 2 in the open position. In the illustrated embodiment of the present invention, the top of the main body 1 is provided with a cham...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com