An integral roof lifting system and an integral roof lifting method

An overall jacking and roofing technology, which is applied in the processing of building materials, construction, building maintenance, etc., can solve the problems of unsuitable roof jacking and easy damage, etc., and achieve a wide range of applications and a stable jacking process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be described in further detail below in conjunction with the accompanying drawings.

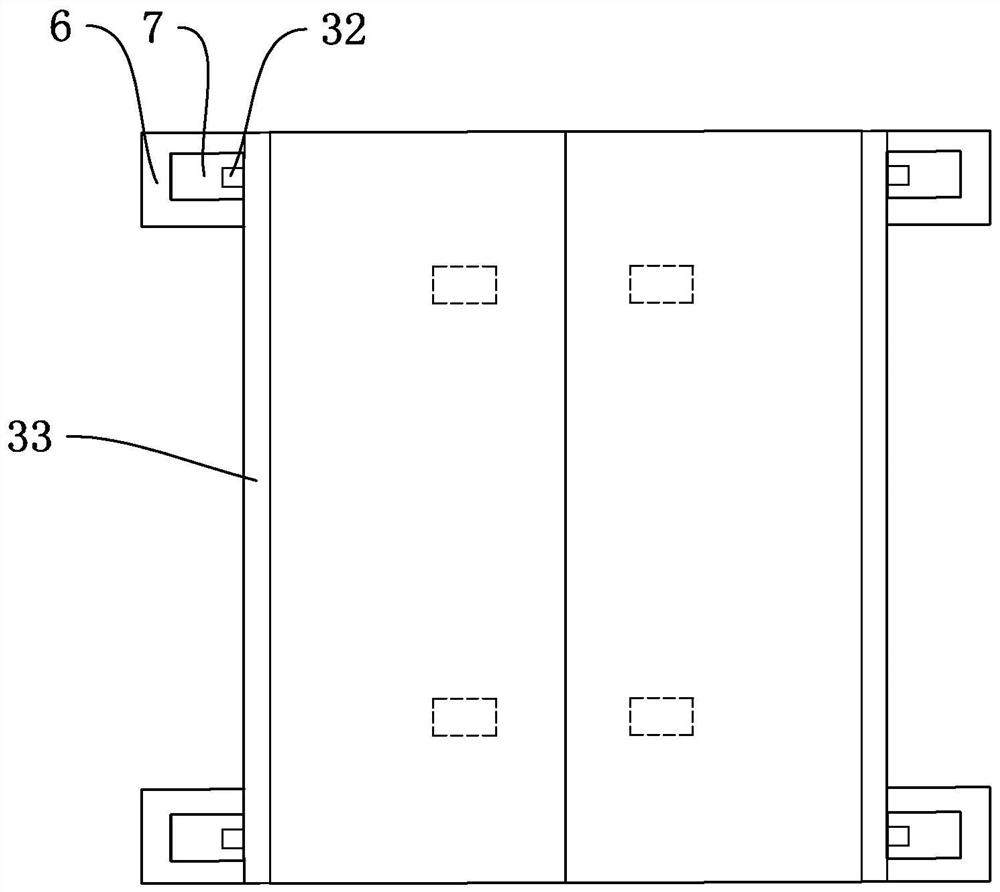

[0035] refer to figure 1 and figure 2, the present invention discloses an integral roof jacking system, comprising a jacking device 1 , a jacking device fixing platform 2 and a beam reinforcement structure 3 . The beam reinforcement structure 3 is made of steel, and the beam reinforcement structure 3 includes several components, and each component module is connected by welding or bolts to form the beam reinforcement structure 3 . The beam reinforcement structure 3 is arranged below the beam to support the beam. The peripheral edge of the beam reinforcement structure 3 penetrates from the top of the wall 4 near the roof 5 and protrudes outward to form an overhang 31 . The overhanging portion 31 is also fixedly provided with a retaining edge 33 for limiting the circumferential edge of the roof 5 , and the retaining edge 33 is an upwardly protruding protrusi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com