Multi-functional micro-fluidic chip and detection method for screening bacterial biofilm inhibitor

A microfluidic chip and inhibitor screening technology, which can be applied in the methods of stress-stimulated microbial growth, biochemical equipment and methods, bioreactors/fermenters for specific purposes, etc., and can solve problems such as limiting the application of microfluidic chips. , to achieve the effect of efficient experimental technology and analytical methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

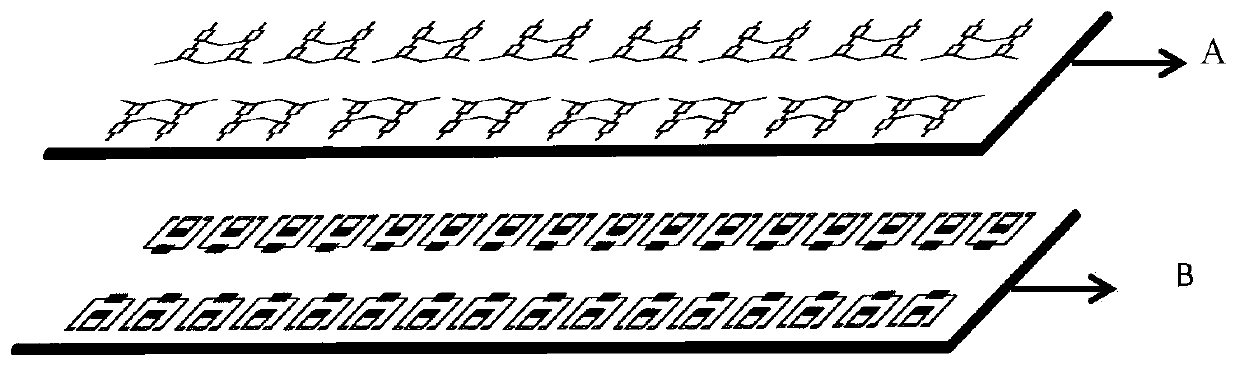

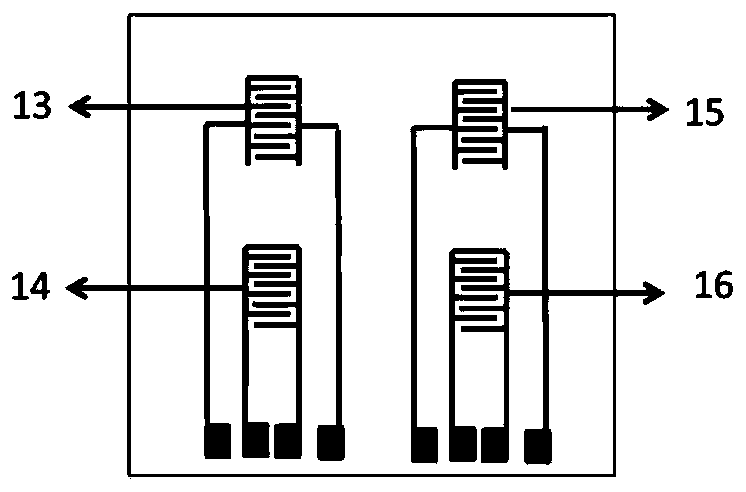

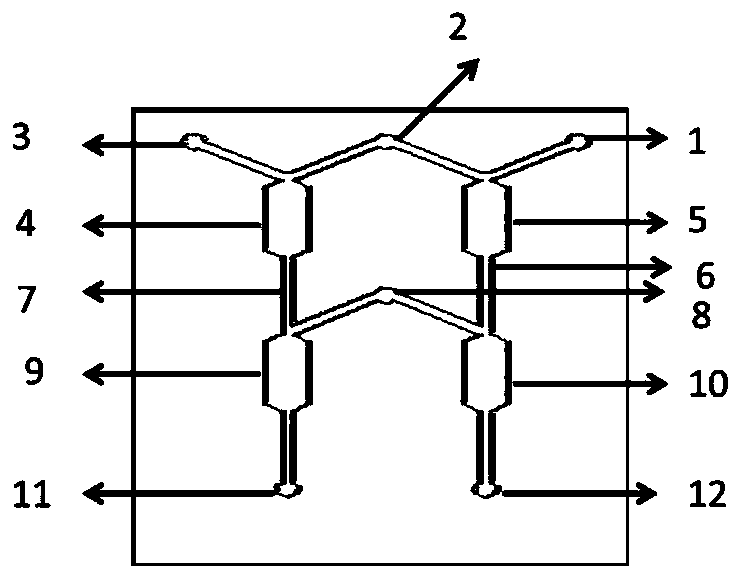

[0031] Such as figure 1 As shown, the multifunctional microfluidic chip for biofilm inhibitor screening is composed of two-layer structure with 16 identical unit structures for online in situ detection of bacterial biofilm and high-pass detection of bacterial biofilm inhibitors. volume synchronization filter. The upper layer is a PDMS cover sheet A with microchannels and detection areas, which contains 16 groups of independent structures arranged in upper and lower layers, with 8 groups of independent structures arranged in each of the upper and lower layers; the lower layer is a glass substrate B with integrated microarray electrodes , 16 groups of interdigitated microarray electrodes are integrated on the glass substrate B, each group includes four identical interdigitated electrodes, and the interdigitated electrode area is opposite to the detection area on the upper layer of the PDMS cover sheet A. Each group of microchannels and detection areas above and each group of in...

Embodiment 2

[0037] The above microfluidic chip is produced through the following steps:

[0038] First, the interdigitated microarray electrodes are fabricated on the glass substrate by MEMS standard technology, that is, the substrate of the microfluidic chip is prepared. Before the assembly of the microfluidic chip, the glass substrate is thoroughly cleaned and then dried for use.

[0039] Select polydimethylsiloxane (PDMS) with good biocompatibility, air permeability and light transmission to make the cover sheet containing microchannels. The specific steps are as follows: PDMS and curing agent are poured into the engraved On the SU8 anodic membrane with microstructure, after removing air bubbles, cure at 80°C for 60-80 minutes. After the PDMS cover slip is solidified, peel it off from the SU8 anodic membrane to obtain a PDMS cover slip with micro-channels.

[0040] After the PDMS cover slip and the glass substrate are sterilized, the PDMS cover slip and the glass substrate are bonded t...

Embodiment 3

[0042] Using the above microfluidic chip to detect the effect of tannic acid on E. coli biofilm:

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com