High-transparency plastic product

A technology of transparent plastics and products, applied in the field of plastic products, can solve the problems of low transparency and achieve the effects of high transparency, low thermal expansion coefficient and increased transparency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

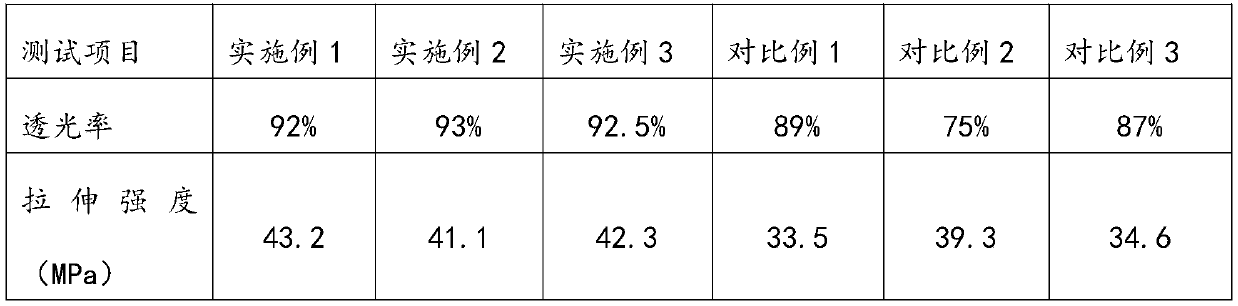

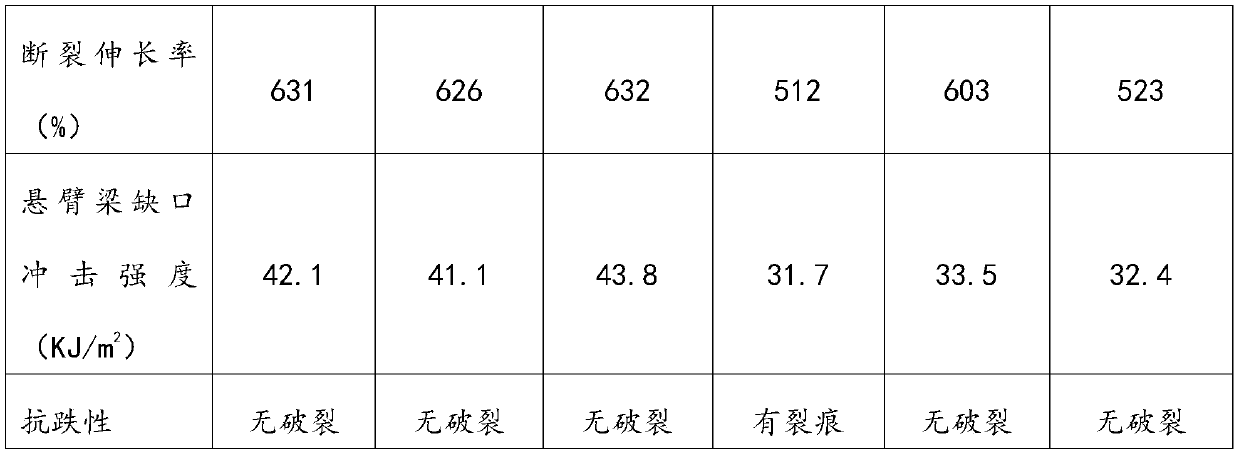

Embodiment 1

[0028] 65g of copolymerized polypropylene, 10g of biaxially oriented polypropylene, 10g of polyolefin thermoplastic elastomer, 1g of tris (2,4 di-tert-butylphenyl) phosphite, 0.1g of benzotriazole, 1g of distilled glyceryl monostearate, 2g of zinc stearate, 1g of EBFF dispersant and 2g of Clariant nucleating agent were added to a twin-screw extruder for melting and plasticization, granulation to obtain plastic pellets, and plasticization The temperature was 140°C. Finally, the obtained plastic pellets were heated and injection-molded, stretched and blow-molded in a blow mold to obtain the highly transparent plastic product of this embodiment, and the molding temperature was 55°C.

Embodiment 2

[0030] 70 g of copolymerized polypropylene, 13 g of biaxially oriented polypropylene, 13 g of polyolefin thermoplastic elastomer, 1.3 g of tris(2,4 di-tert-butylphenyl) phosphite, 0.3 g of benzotriazole , 1.5g of distilled glyceryl monostearate, 3g of zinc stearate, 1.5g of EBFF dispersant and 2g of Clariant nucleating agent are added to the twin-screw extruder for melting and plasticization, and pelletized to obtain plastic pellets , The plasticizing temperature is 140°C. Finally, the obtained plastic pellets were heated and injection-molded, stretched and blow-molded in a blow mold to obtain the highly transparent plastic product of this embodiment, and the molding temperature was 55°C.

Embodiment 3

[0032] 75 g of copolymerized polypropylene, 15 g of biaxially oriented polypropylene, 15 g of polyolefin thermoplastic elastomer, 1.5 g of tris(2,4 di-tert-butylphenyl) phosphite, 0.5 g of benzotriazole , 2g of distilled glyceryl monostearate, 5g of zinc stearate, 2g of EBFF dispersant and 2g of Clariant nucleating agent were added to the twin-screw extruder for melting and plasticization, and pelletized to obtain plastic pellets. The melting temperature is 140°C. Finally, the obtained plastic pellets were heated and injection-molded, stretched and blow-molded in a blow mold to obtain the highly transparent plastic product of this embodiment, and the molding temperature was 55°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com