A kind of synthetic method of water-swellable body material

A technology of water-swelling body and synthesis method, which is applied in the field of polymer materials, can solve the problems of slow water-absorbing swelling rate, small water-absorbing swelling rate, and decreased mechanical properties, and achieve fast water-absorbing rate, high water-absorbing expansion rate, and mechanical property change. small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

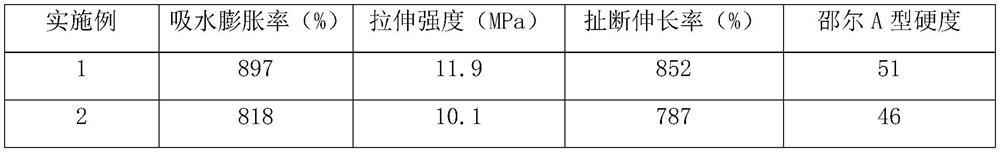

Embodiment 1

[0037] Inject 8.5 kg of ethylene oxide and 1.5 kg of propylene oxide into a sealed container with stirring with nitrogen pressure, and stir for 30 minutes to fully mix the materials. Add 80 g of initiator pentaerythritol and 30 g of potassium hydroxide into the reaction kettle, use a vacuum pump to remove the air in the reaction kettle, and then flush into nitrogen protection. Reactor is heated to 55 ℃, slowly press into the premixed material 10kg of ethylene oxide and propylene oxide, make it react. Adjust the feeding valve to keep the temperature in the reactor at 100°C and the pressure at 4kPa all the time, and keep cooling the temperature in the reactor with water. After adding the premixed materials, keep the temperature in the kettle and make the pressure drop to 0 slowly. Press the reacted coarse material into a neutralization kettle, add 45 g of neutralizing agent phosphoric acid and 50 g of refining agent aluminum hydroxide, stir for 1 hour, filter and pack to obtain...

Embodiment 2

[0039] Put 8 kg of ethylene oxide and 1 kg of propylene oxide into a sealed container with stirring with nitrogen pressure, and stir for 30 minutes to fully mix the materials. Add 50 g of initiator pentaerythritol and 10 g of potassium hydroxide into the reaction kettle, use a vacuum pump to remove the air in the reaction kettle, and then flush into nitrogen protection. Reactor is heated to 55 DEG C, slowly press into the premixed material 9kg of ethylene oxide and propylene oxide, make it react. Adjust the feeding valve to keep the temperature in the reactor at 100°C and the pressure at 4kPa all the time, and keep cooling the temperature in the reactor with water. After adding the premixed materials, keep the temperature in the kettle and make the pressure drop to 0 slowly. Press the reacted coarse material into a neutralization kettle, add 30 g of neutralizing agent phosphoric acid and 30 g of refining agent aluminum hydroxide, stir for 1 hour, filter and package to obtain ...

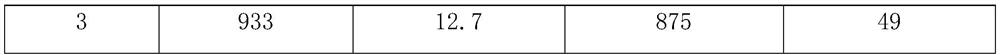

Embodiment 3

[0041]Put 9 kg of ethylene oxide and 2 kg of propylene oxide into a sealed container with stirring with nitrogen pressure, and stir for 30 minutes to make the materials fully mixed. Add 100 g of initiator pentaerythritol and 50 g of potassium hydroxide into the reaction kettle, use a vacuum pump to remove the air in the reaction kettle, and then flush into nitrogen protection. Reactor is heated to 55 ℃, slowly presses into 11kg of the premixed material of ethylene oxide and propylene oxide, makes it react. Adjust the feeding valve to keep the temperature in the reactor at 100°C and the pressure at 4kPa all the time, and keep cooling the temperature in the reactor with water. After adding the premixed materials, keep the temperature in the kettle and make the pressure drop to 0 slowly. Press the reacted coarse material into a neutralization kettle, add 50 g of neutralizing agent phosphoric acid and 70 g of refining agent aluminum hydroxide, stir for 1 hour, filter and pack to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com