A kind of composite medical hydrogel dressing material and preparation method thereof

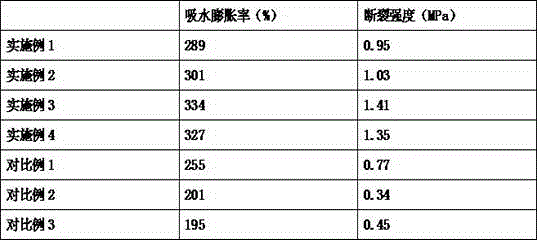

A hydrogel and medical technology, applied in the field of medical dressing materials and their preparation, can solve the problems of reducing the mechanical strength and low breaking strength of hydrogels, achieve good biocompatibility, improve the breaking strength, and increase the water absorption swelling rate. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] (1) Take deionized water and pour it into the reactor, raise the temperature of the reactor to 65°C, and slowly add alginic acid with a molecular weight of 20-100kDa and gelatin with a molecular weight of 25-60kDa into the reactor after the temperature stabilizes, add Mechanically stir the alginic acid and gelatin at the same time, and the mechanical stirring speed is 150r / min; (2) After adding the alginic acid and gelatin, continue to stir for 15 minutes, and then add polyvinyl alcohol and hydroxypropyl alcohol with a molecular weight of 100-150kDa to the reactor Methyl cellulose and propylene glycol were added while being mechanically stirred at a stirring speed of 60r / min; (3) After the above materials were mixed, the hydrogel was cooled to room temperature, and the alginic acid in the prepared hydrogel dressing material 25wt% gelatin, 3wt% polyvinyl alcohol, 20wt% hydroxypropyl methylcellulose, 5wt% propylene glycol, and water as the balance.

Embodiment 2

[0035] (1) Take deionized water and pour it into the reactor, raise the temperature of the reactor to 85°C, and slowly add alginic acid with a molecular weight of 20-100kDa and gelatin with a molecular weight of 25-60kDa into the reactor after the temperature stabilizes, add Mechanically stir the alginic acid and gelatin at the same time, and the mechanical stirring speed is 100r / min; (2) After adding the alginic acid and gelatin, continue to stir for 10min, and then add polyvinyl alcohol and hydroxypropyl alcohol with a molecular weight of 100-150kDa to the reactor Methyl cellulose and propylene glycol were added while being mechanically stirred at a stirring speed of 30r / min; (3) After the above materials were mixed, the hydrogel was cooled to room temperature, and the alginic acid in the prepared hydrogel dressing material 10wt% gelatin, 10wt% polyvinyl alcohol, 5wt% hydroxypropyl methylcellulose, 2wt% propylene glycol, and water as the balance.

Embodiment 3

[0037] (1) Take deionized water and pour it into the reactor, raise the temperature of the reactor to 65°C, and slowly add alginic acid with a molecular weight of 20-100kDa and gelatin with a molecular weight of 25-60kDa into the reactor after the temperature stabilizes, add Mechanically stir the alginic acid and gelatin at the same time, and the mechanical stirring speed is 150r / min; (2) After adding the alginic acid and gelatin, continue to stir for 15 minutes, and then add polyvinyl alcohol and hydroxypropyl alcohol with a molecular weight of 100-150kDa to the reactor Methyl cellulose and propylene glycol were added while being mechanically stirred at a stirring speed of 60r / min; (3) After the above materials were mixed, the hydrogel was cooled to room temperature, and the alginic acid in the prepared hydrogel dressing material 20wt% gelatin, 5wt% polyvinyl alcohol, 15wt% hydroxypropyl methylcellulose, 3wt% propylene glycol, and water as the balance.

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com