Electric boiler water chemical treatment method

A treatment method and boiler furnace technology, applied in the field of phosphate treatment, can solve problems such as no corresponding treatment method, low electric boiler load, damage to electrode insulation parts, etc., to ensure safe, economical and stable operation, reduce operating power consumption, and reduce The effect of corrosion

Inactive Publication Date: 2019-12-03

HUANENG SHANDONG SHIDAOBAY NUCLEAR POWER CO LTD

View PDF4 Cites 5 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

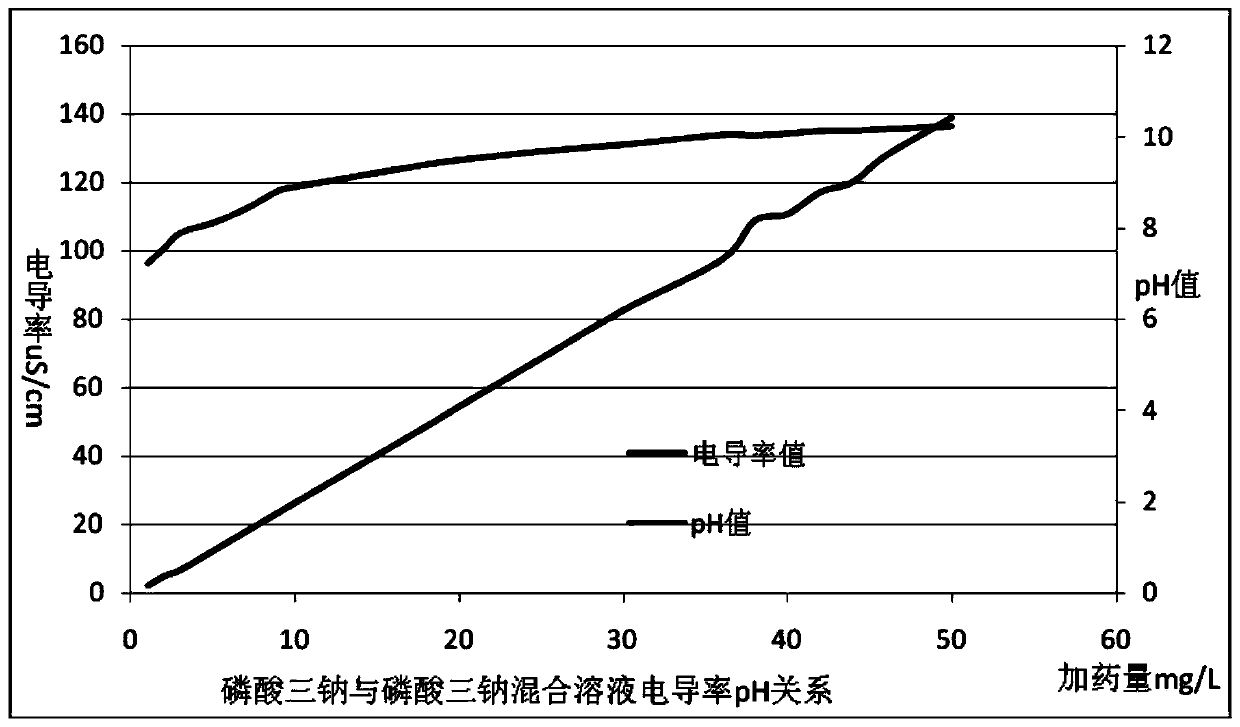

When the conductivity of the boiler water meets the requirements, the pH value is too high, which will cause damage to the electrode insulation, and when the pH value of the boiler water meets the requirements, the conductivity is low, resulting in a low load on the electric boiler

[0004] In the prior art, there is no corresponding treatment method for the relationship between conductivity and pH of electric boiler water

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

[0023] (1) According to the 1:3 ratio of trisodium phosphate and disodium hydrogen phosphate, respectively weigh trisodium phosphate and disodium hydrogen phosphate into the metering box, and add an appropriate amount of demineralized water to prepare a trisodium phosphate with a concentration of 0.75%. Chemical solution, when the electric boiler is started, start the dosing pump for chemical addition;

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention provides an electric boiler water chemical treatment method. The electric boiler water chemical treatment method comprises the following steps: weighing trisodium phosphate and disodiumhydrogen phosphate separately, adding the trisodium phosphate and the disodium hydrogen phosphate into a metering box, adding desalted water, preparing a medicament solution added into the electric boiler water, starting a dosing pump when the electric boiler starts and adding the medicaments; and sampling the electric boiler water through a centralized sampling rack, setting the temperature of awater sample, detecting the pH value and the conductivity of the boiler water by a pH meter and a conductivity instrument correspondingly, and detecting the iron content of the boiler water by an atomic absorption instrument, wherein sampling and analysis are conducted for one time every day in the operation period of the electric boiler, the pH value and the conductivity of the boiler water are measured, and the conductivity of the electric boiler water maintains a high level while the pH value meets the requirement. The electric boiler water chemical treatment method has the characteristicsof meeting the designed chemical treatment requirement and guaranteeing safe, economic and stable operation of the electric boiler.

Description

technical field [0001] The invention relates to the technical field of phosphate treatment, in particular to a chemical treatment method for electric boiler furnace water. Background technique [0002] The load of the high-voltage electrode boiler is related to the conductivity of the boiler water. The higher the conductivity, the higher the power of the electric boiler. [0003] The boiler water design of the electric boiler uses trisodium phosphate to adjust the conductivity and pH value of the boiler water. When the conductivity of the boiler water meets the requirements, the pH value is high, which will cause damage to the electrode insulation. When the pH value of the boiler water meets the requirements, the conductivity is low, resulting in a low load on the electric boiler. [0004] In the prior art, there is no corresponding treatment method for the relationship between conductivity and pH of electric boiler water. Contents of the invention [0005] In order to o...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C02F1/66

CPCC02F1/66C02F2209/05C02F2209/06C02F2303/08

Inventor 姚洪猛马倩韩成杨康

Owner HUANENG SHANDONG SHIDAOBAY NUCLEAR POWER CO LTD

Features

- Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com