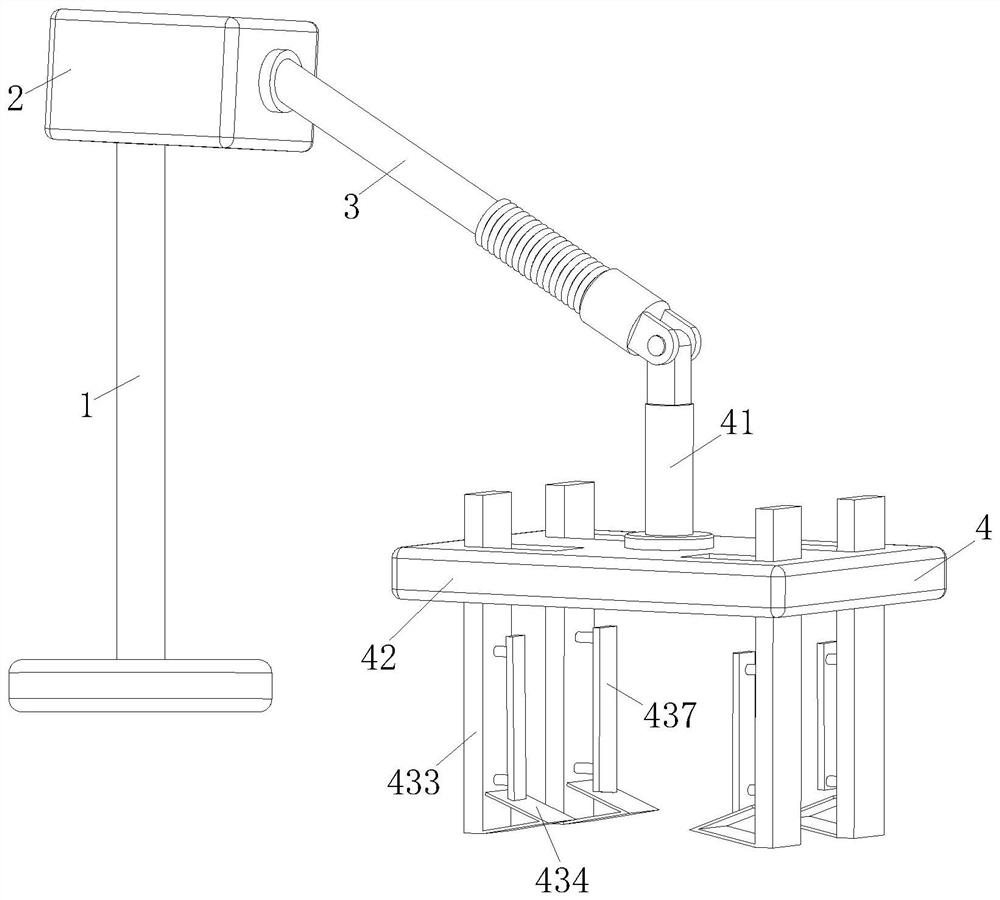

A palletizing robot

A manipulator and palletizing technology, which is applied in the direction of packaging, packaging item types, special packaging items, etc., can solve the problems that affect the quality of ceramic tile processing, prone to bumping, tile damage, etc., to reduce the probability of breaking and reduce being knocked , reduce the effect of rigid collision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

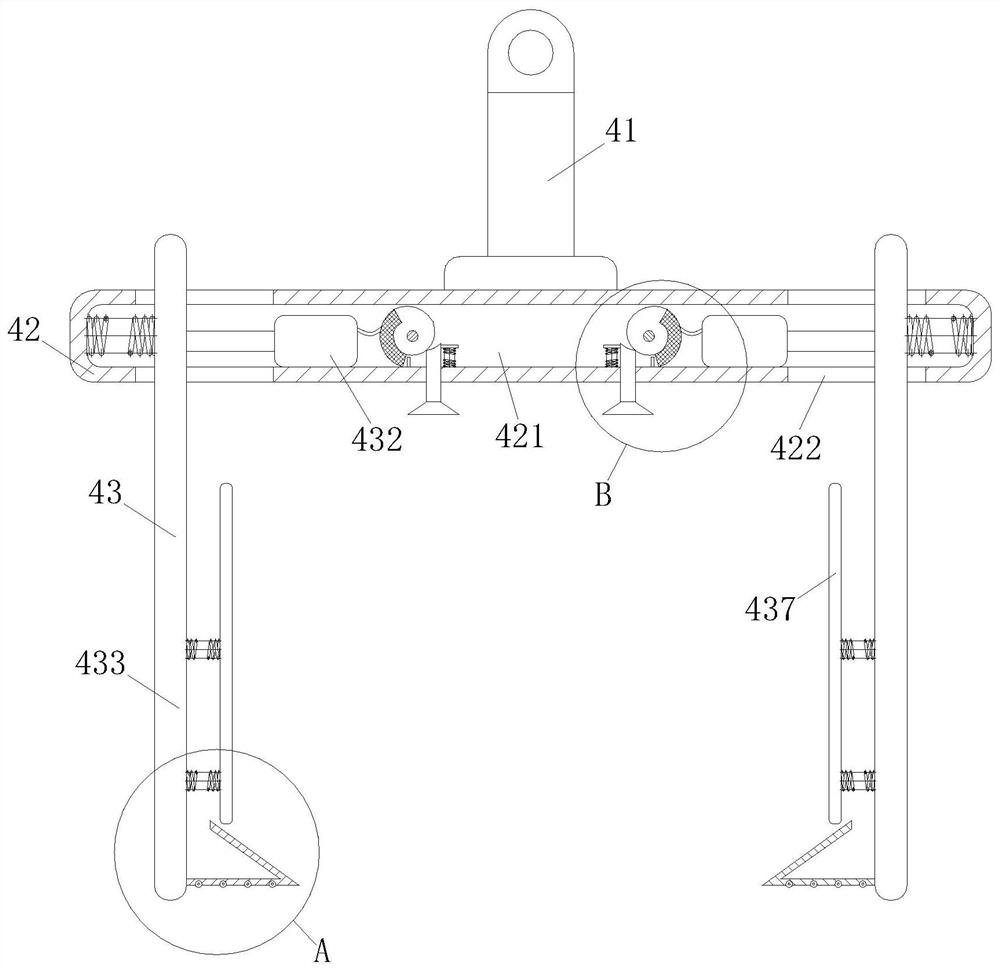

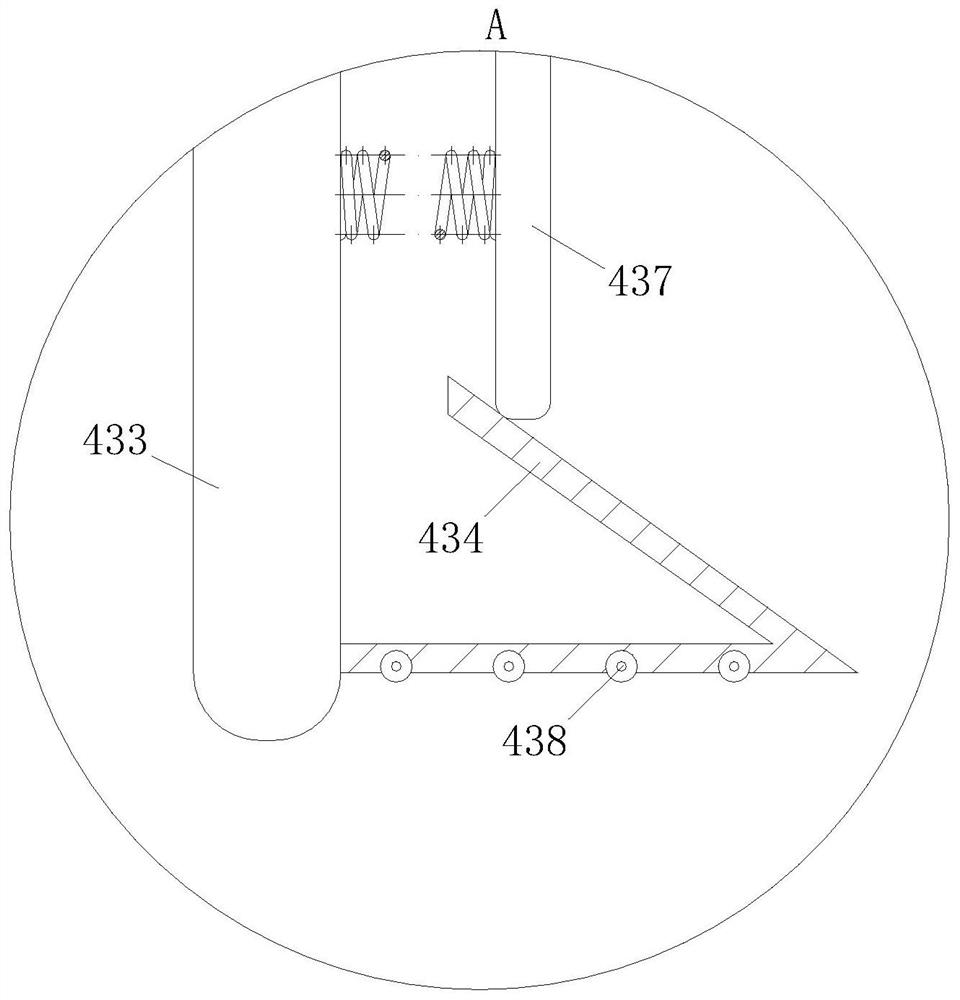

[0021] As an embodiment of the present invention, the gripping platform 42 is slidably connected with a suction cup column 423 on the side wall close to the tile; one end of the suction cup column 423 is in contact with the spiral wheel 431, and the other end is installed with a suction cup 424 and extends out. The grabbing platform 42 can be in contact with the tiles, and the side wall of the suction cup column 423 is connected with the side wall of the cavity 421 by a spring; the fixing of the tiles is realized through the cooperation of the spiral wheel 431 and the sucker column 423; during work, when the grabbing platform 42 moves down When reaching the specified position, control the rotation of the helical wheel 431 through the control box 2, so that the arc-shaped air bag 435 is elastically recovered. Move to the direction close to the middle respectively, so as to grab the tiles. During the rotation of the spiral wheel 431, the suction cup column 423 will be squeezed, s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com