High-power motor operating mechanism control device and method

A technology of operating mechanism and control device, which is applied in the direction of single motor speed/torque control, protection switch operation/release mechanism, electronic commutator, etc., and can solve the problem that the high-precision position control of the moving arc contact in the circuit breaker cannot be realized , single-speed motion characteristics, opening or closing motion, and limited state detection range, etc., to achieve the effects of reducing stator copper consumption, small torque ripple, and reducing motion speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The specific embodiments of the present invention will be described in further detail below in conjunction with the drawings and embodiments. The following examples are used to illustrate the present invention, but not to limit the scope of the present invention.

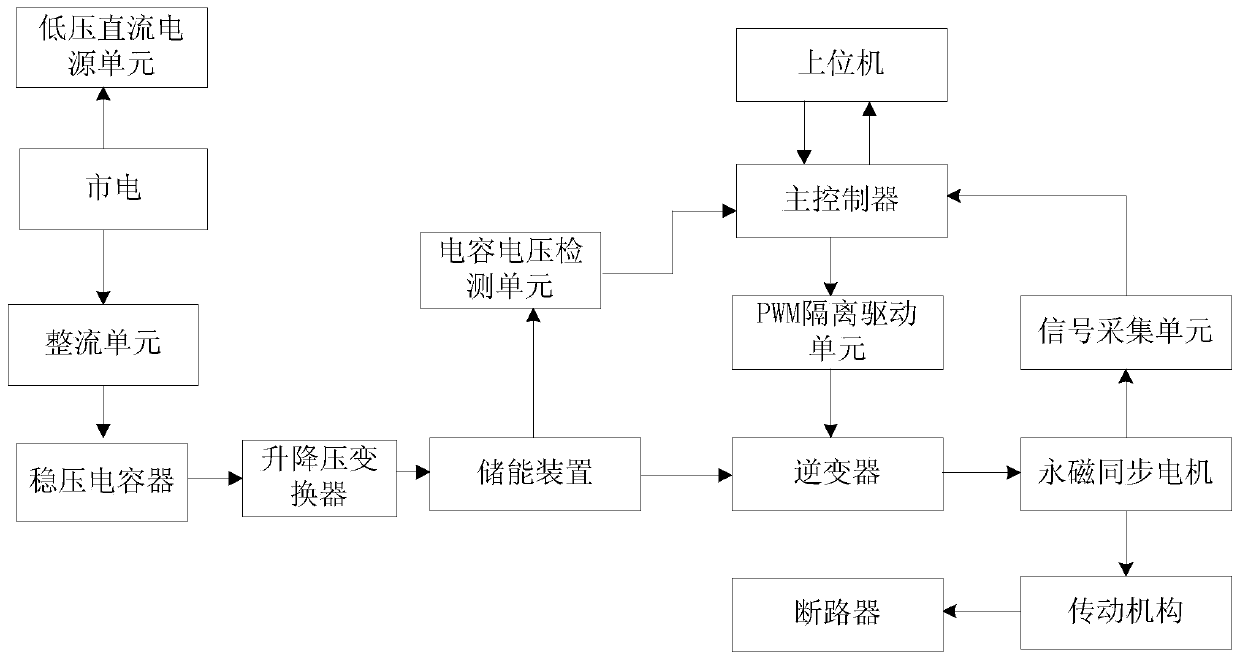

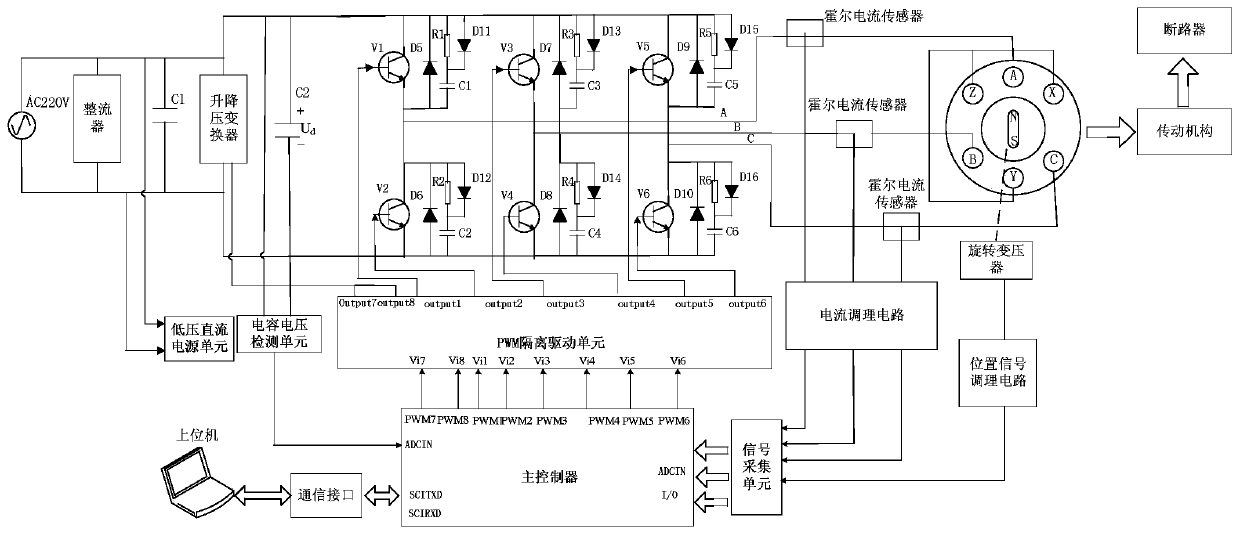

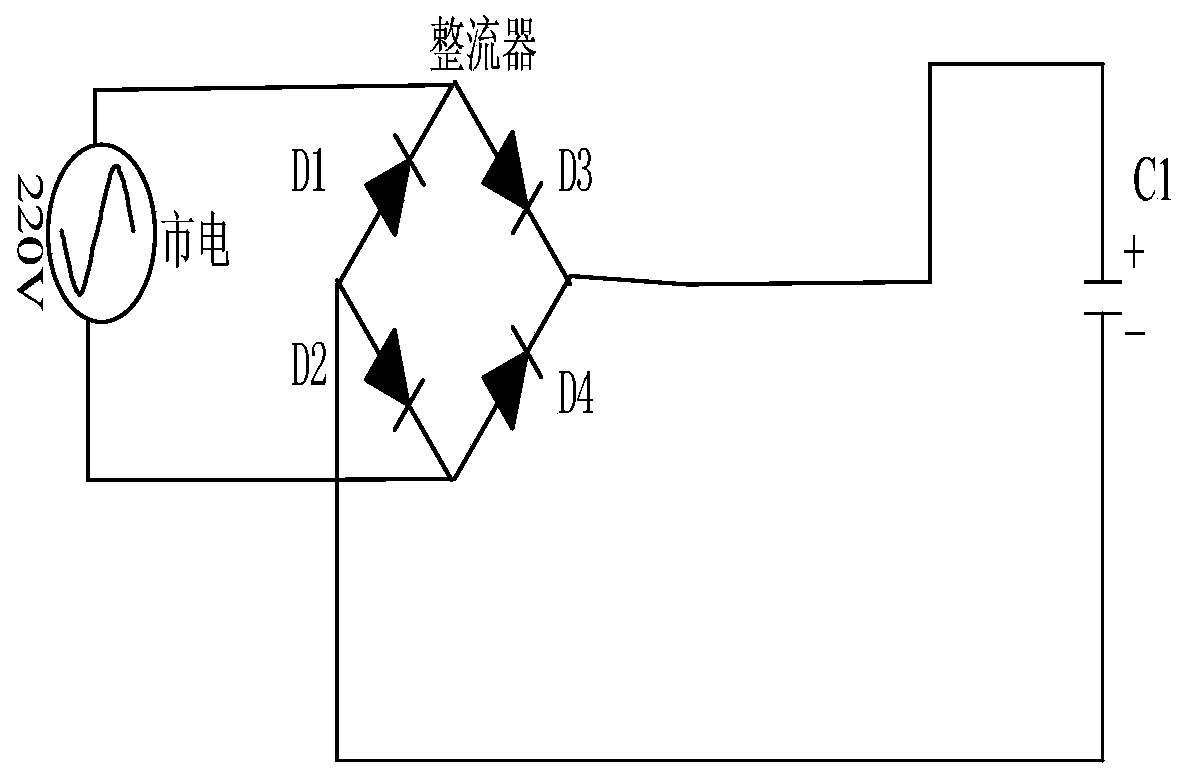

[0036] In this embodiment, a high-power motor operating mechanism control device, such as figure 1 As shown, it includes a rectifier unit, a voltage stabilizing capacitor, a buck-boost converter, an energy storage device, a signal acquisition unit, a signal processing unit, an inverter, a main controller, a current conditioning circuit, a position signal conditioning circuit, and a capacitor voltage detection unit , Host computer, PWM (Pulse Width Modulation, that is, pulse width modulation) isolation drive unit and low-voltage DC power supply;

[0037] In this embodiment, the circuit connection relationship of the high-power motor operating mechanism control device of the present invention is as follows figure 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com