Marine airbag vibration isolator

A vibration isolator, airbag technology, applied in gas shock absorbers, shock absorbers, shock absorbers, etc., can solve the problems of reducing the natural frequency of the air spring, increasing the weight of the air spring, and reducing the volume of the enclosed space, etc. Achieve the effect of reduced stiffness, large load-carrying capacity, and reduced chance of rigid collision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

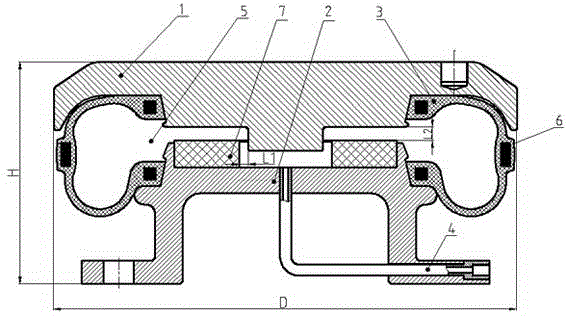

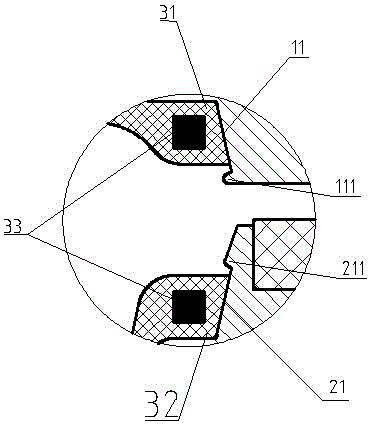

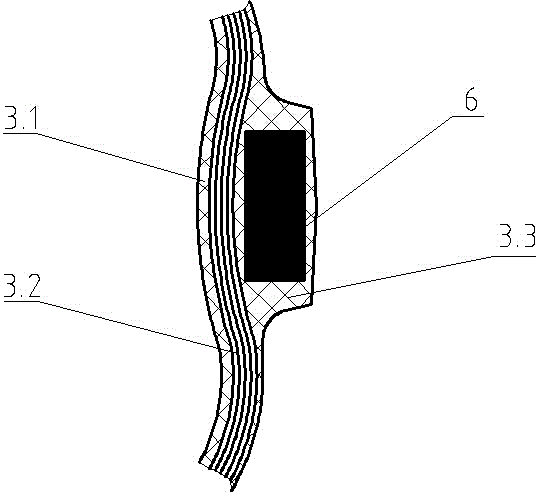

[0020] Such as Figure 1 to Figure 3 As shown, the naval airbag vibration isolator includes top plate 1, base 2 and middle airbag 3 from top to bottom. Into the closed space 5, the waist position of the middle airbag 3 is provided with a restraint belt 6 surrounding the middle airbag 3, and the restraint belt 6 is placed inside the capsule body of the middle airbag 3 and faces the said middle airbag 3. The outer side of the closed space 5 protrudes so that it does not occupy the inner space of the closed space 5 and ensures the maximum volume of the closed space 5. A buffer pad 7 is installed on the base 2, and the buffer pad 7 is placed on the Inside the enclosed space 5, the horizontal distance and the vertical distance from the buffer pad 7 to the top plate 1 are L1 and L2 respectively, and the values of L1 and L2 both range from 1 mm to 20 m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com