PVC-based color-changing artificial leather for vehicle and preparation method of PVC-based color-changing artificial leather

A technology for artificial leather and vehicles, which is applied in the field of PVC-based color-changing artificial leather for vehicles and its preparation. It can solve the problems of uneven dispersion and stability of color-changing materials, wear resistance, flame retardancy, low odor, and uneven color of color-changing leather. , to achieve strong bonding, avoid splitting, and enhance durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] The preparation method of the above-mentioned PVC-based color-changing artificial leather for vehicles comprises the following steps: (a) placing the surface layer coating solution on a coating machine, and drying at 150°C to 200°C to obtain the surface layer; (b) A foam layer is formed on the surface of the surface layer; (c) a base cloth is pasted on the foam layer; (d) a water-based surface treatment layer is formed on the other surface of the surface layer. Specifically, in step (b), the foam layer is obtained by coating the foam layer coating liquid on the surface of the surface layer, drying and curing at 150°C to 180°C; in step (d), the The water-based surface treatment layer is obtained by coating the water-based coating solution on the surface of the surface layer, drying and curing at 100°C to 120°C.

[0029] Preferred embodiment of the present invention will be described in detail below:

Embodiment 1

[0031] This embodiment provides a kind of PVC-based color-changing artificial leather for vehicles, which includes a surface layer, a water-based surface treatment layer formed on any surface of the surface layer, a foam layer formed on the other surface of the surface layer, and a foam layer formed outside the foam layer. The base fabric layer on the surface and the surface layer are obtained by curing the surface layer coating liquid;

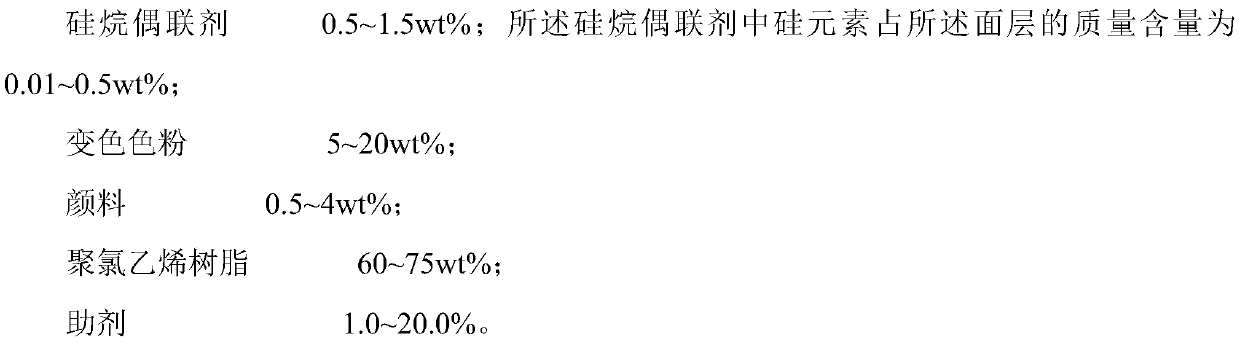

[0032] The above-mentioned layers are obtained by drying the corresponding coating liquid, and the specific coating liquid configuration is as follows (the following are the mass contents):

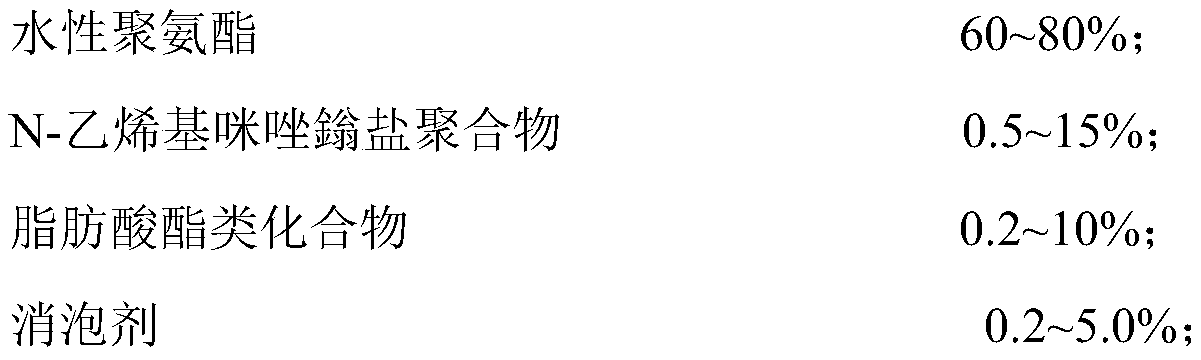

[0033] Water-based coating liquid configuration: add polyvinyl chloride resin 78%, N-vinylimidazolium salt polymer (number average molecular weight 1000) 13%, 2,2,4-trimethyl-1,3-pentanedi 5% alcohol monoisobutyrate, 1% defoamer BYK1790, 1% carboxymethyl cellulose, 2% polymethylurea resin (data molecular weight 1000), fully stirred at room temperature fo...

Embodiment 2

[0042] This embodiment provides a kind of PVC-based discoloration artificial leather for vehicles and a preparation method thereof, which is basically the same as that in Example 1, except that the surface layer coating solution contains the following components by mass:

[0043] Silane coupling agent (vinyltrimethoxysilane, Nanjing Chengong organic silicon CG171) 1.5% (0.28% based on silicon element), temperature-sensitive toner JY031 (Shenzhen Jingyizi Technology Co., Ltd., 31 degrees from colorless to Red temperature-sensitive toner) 10%, pigment (black) 10%, then add polyvinyl chloride resin 49.0%, phthalate plasticizer 25%, calcium zinc stabilizer 2.0%, calcium carbonate inorganic filler 2.5%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com