Three-fiber composite reinforced epoxy ground material and preparation method thereof

A composite reinforcement and ground material technology, applied in the field of building decoration materials, can solve the problems of weak tensile strength and creep resistance, poor low temperature crack resistance and fatigue resistance, and achieve high stability, uniform thickness and easy construction The effect of laying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

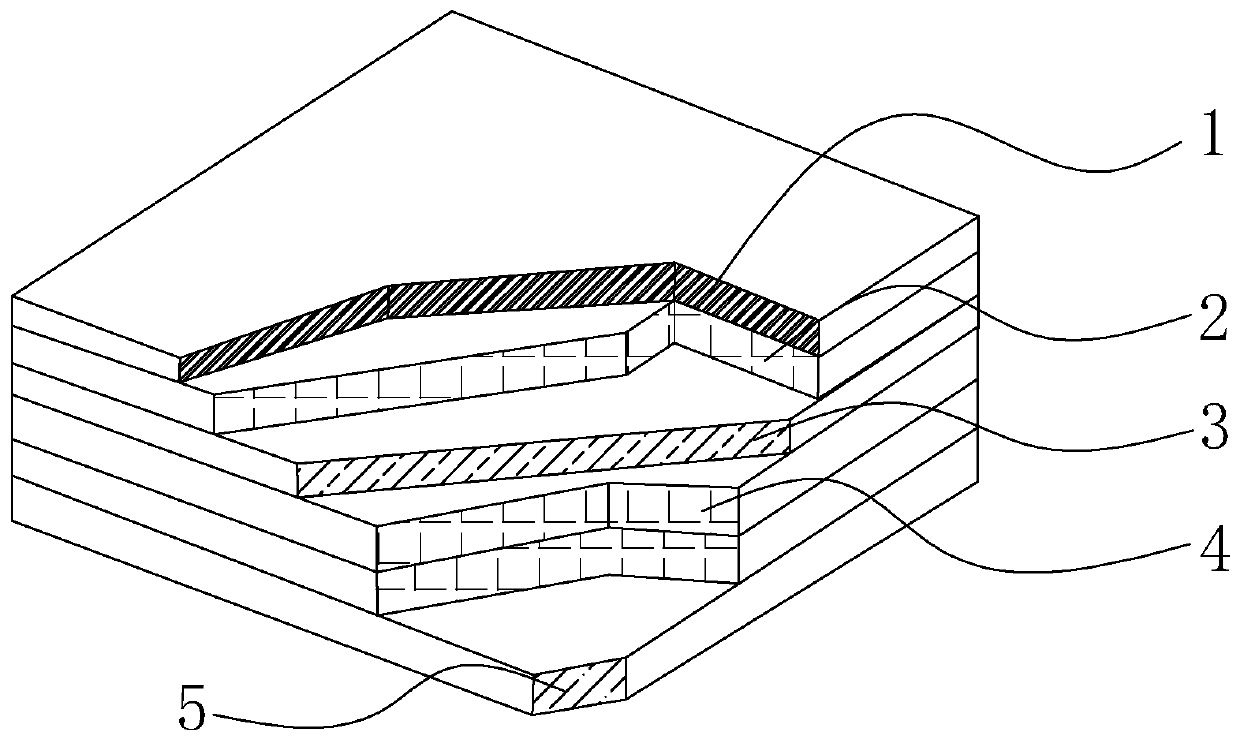

[0031] A three-fiber composite reinforced epoxy floor material, combined with figure 1 As shown, it includes a long-fiber polyester layer 1, a first epoxy resin layer 2, a glass fiber layer 3, a second epoxy resin layer 4, and a short-fiber polyester layer 5 sequentially compounded from top to bottom. Wherein, the long-fiber polyester layer 1 is a polyester long-fiber warp-knitted cloth with a thickness of 0.6mm, the glass fiber layer 3 is a glass fiber mesh cloth with a thickness of 0.15mm, and the short-fiber polyester layer 5 is a polyester mesh with a thickness of 0.45mm. Polyester staple fiber felt. The thickness ratio of the first epoxy resin layer 2 and the second epoxy resin layer 4 is 1-2.

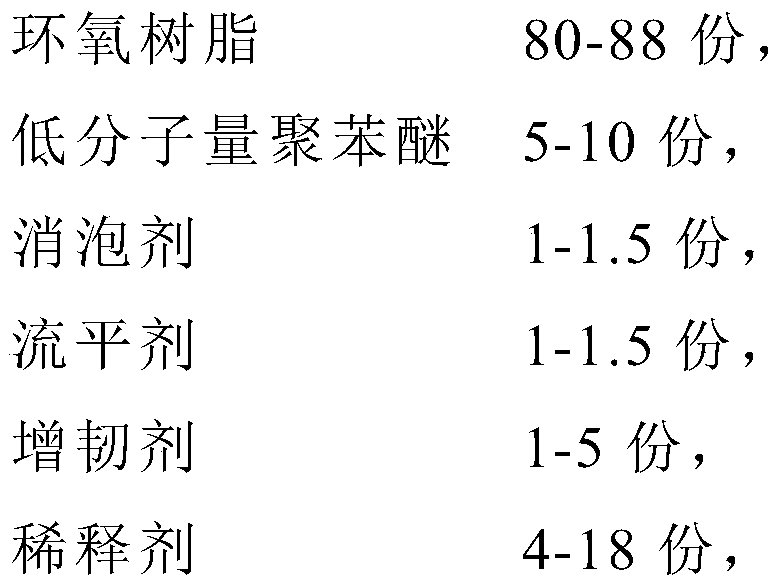

[0032] The weight ratio of the epoxy resin component and the curing agent in the epoxy coating used in this embodiment is 4:1. According to the ratio of 100 kilograms of paint, the raw materials of the epoxy paint are as follows, and the following raw materials are commercially ...

Embodiment 2

[0050] A three-fiber composite reinforced epoxy floor material, combined with figure 1 As shown, it includes a long-fiber polyester layer 1, a first epoxy resin layer 2, a glass fiber layer 3, a second epoxy resin layer 4, and a short-fiber polyester layer 5 sequentially compounded from top to bottom. Wherein, the long-fiber polyester layer 1 is a polyester long-fiber warp-knitted cloth with a thickness of 1 mm, the glass fiber layer 3 is a glass fiber mesh cloth with a thickness of 0.25 mm, and the short-fiber polyester layer 5 is a polyester with a thickness of 0.6 mm. Ester staple fiber linoleum. The thickness ratio of the first epoxy resin layer 2 and the second epoxy resin layer 4 is 1-2.

[0051] The weight ratio of the epoxy resin component and the curing agent in the epoxy coating used in this embodiment is 4:1. According to the ratio of 100 kilograms of paint, the raw materials of the epoxy paint are as follows, and the following raw materials are commercially avail...

Embodiment 3

[0067] A three-fiber composite reinforced epoxy floor material, combined with figure 1 As shown, it includes a long-fiber polyester layer 1, a first epoxy resin layer 2, a glass fiber layer 3, a second epoxy resin layer 4, and a short-fiber polyester layer 5 sequentially compounded from top to bottom. Wherein, the long-fiber polyester layer 1 is a polyester long-fiber warp-knitted cloth with a thickness of 1.5mm, the glass fiber layer 3 is a glass fiber mesh cloth with a thickness of 0.3mm, and the short-fiber polyester layer 5 is a polyester mesh with a thickness of 0.8mm. Polyester staple fiber linoleum. The thickness ratio of the first epoxy resin layer 2 and the second epoxy resin layer 4 is 1-3.

[0068] The weight ratio of the epoxy resin component and the curing agent in the epoxy coating used in this embodiment is 5:1. According to the ratio of 100 kilograms of paint, the raw materials of the epoxy paint are as follows, and the following raw materials are commerciall...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com