Full-automatic punching machine and punching operation method thereof

A punching machine, fully automatic technology, applied in the direction of static electricity, metal processing, electrical components, etc., can solve the problems that cannot be used as punching operations, cannot be processed globally, and cannot be punched.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to enable your committee members to have a deeper understanding and recognition of the features, purposes and effects of the present invention, a preferred embodiment is hereby listed and described in conjunction with the drawings as follows:

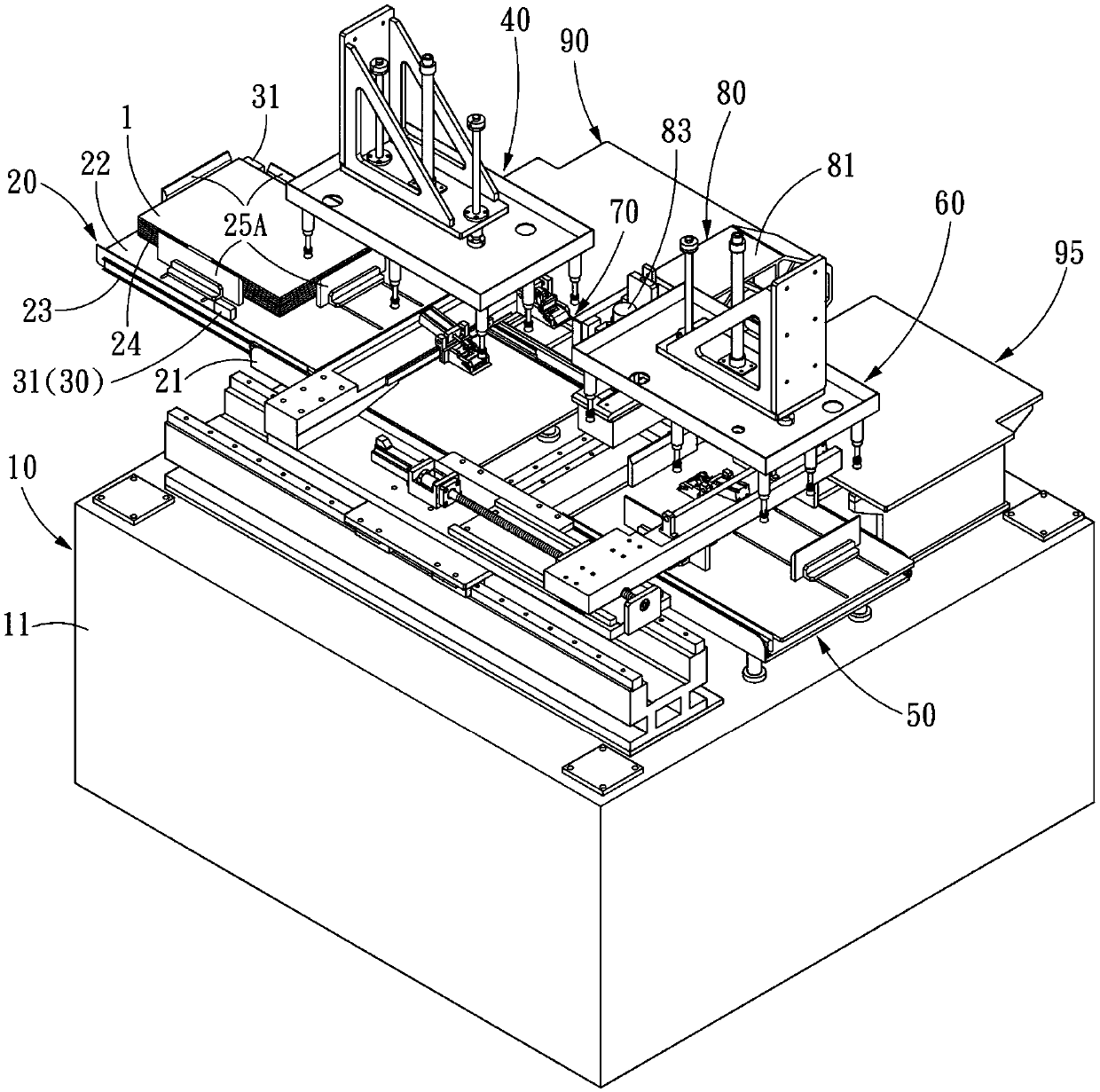

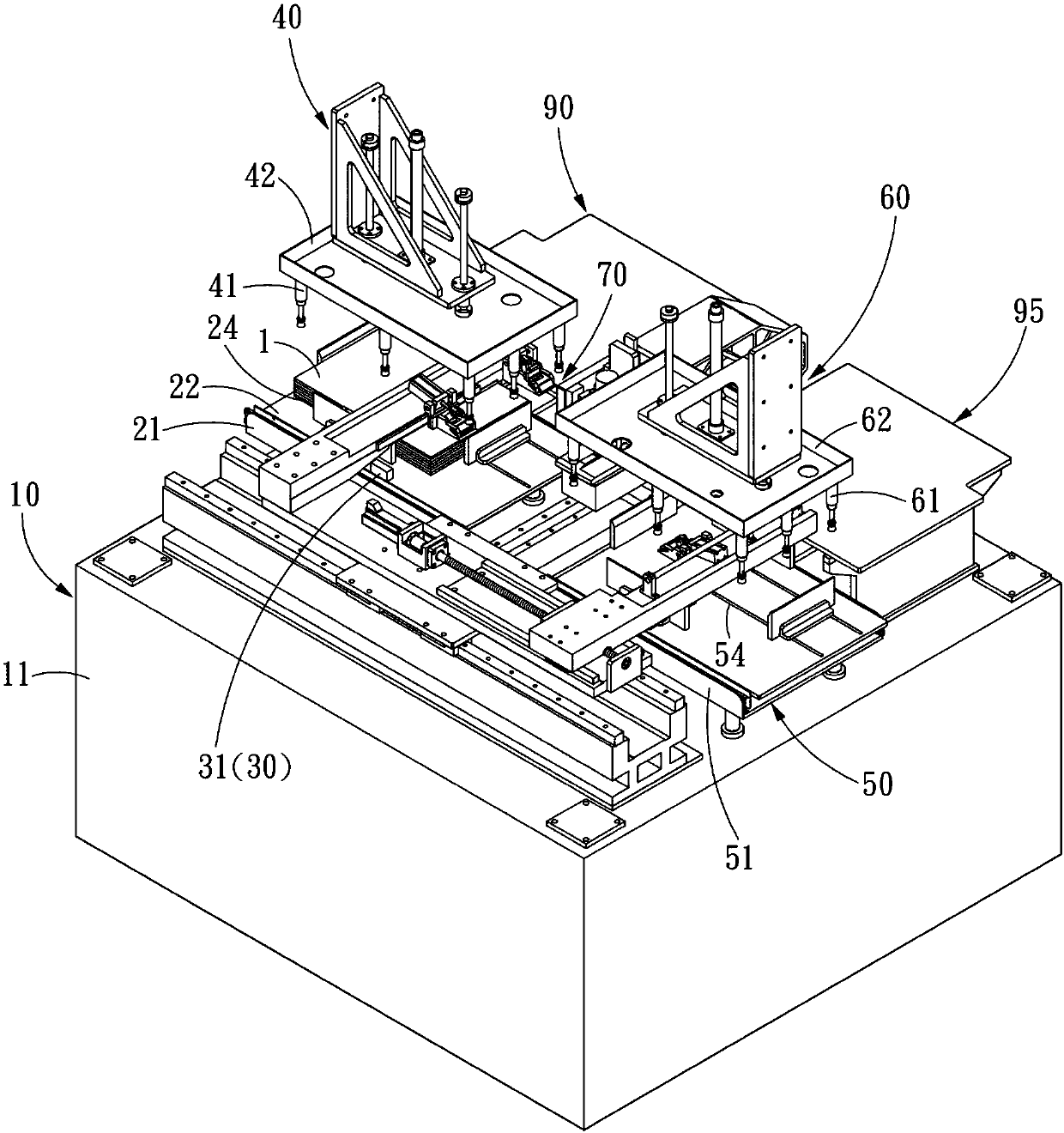

[0021] see figure 1 As shown, the present invention is a fully automatic punching machine, which is used for punching a plurality of workpieces 1. Its structure includes a body 10, a drawer type feeding device 20, a blowing device 30, a feeding suction Nozzle device 40 , a drawer type discharge device 50 , a discharge suction nozzle device 60 , a clamping device 70 and a punching device 80 . The machine body 10 has a platform 11 and a hanger 12 arranged above the platform 11, the drawer-type feeding device 20, the drawer-type discharging device 50, the clamping device 70 and the punching device 80 are arranged on the The platform 11 , and the feeding nozzle device 40 and the discharging nozzle device 60 are hung on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com