Cutting machine for fitness equipment production

A fitness equipment and cutting machine technology, which is applied to metal processing machinery parts, large fixed members, clamping and other directions, can solve the problems of low work efficiency and poor accuracy, and achieve the effect of improving work efficiency, high precision and easy movement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

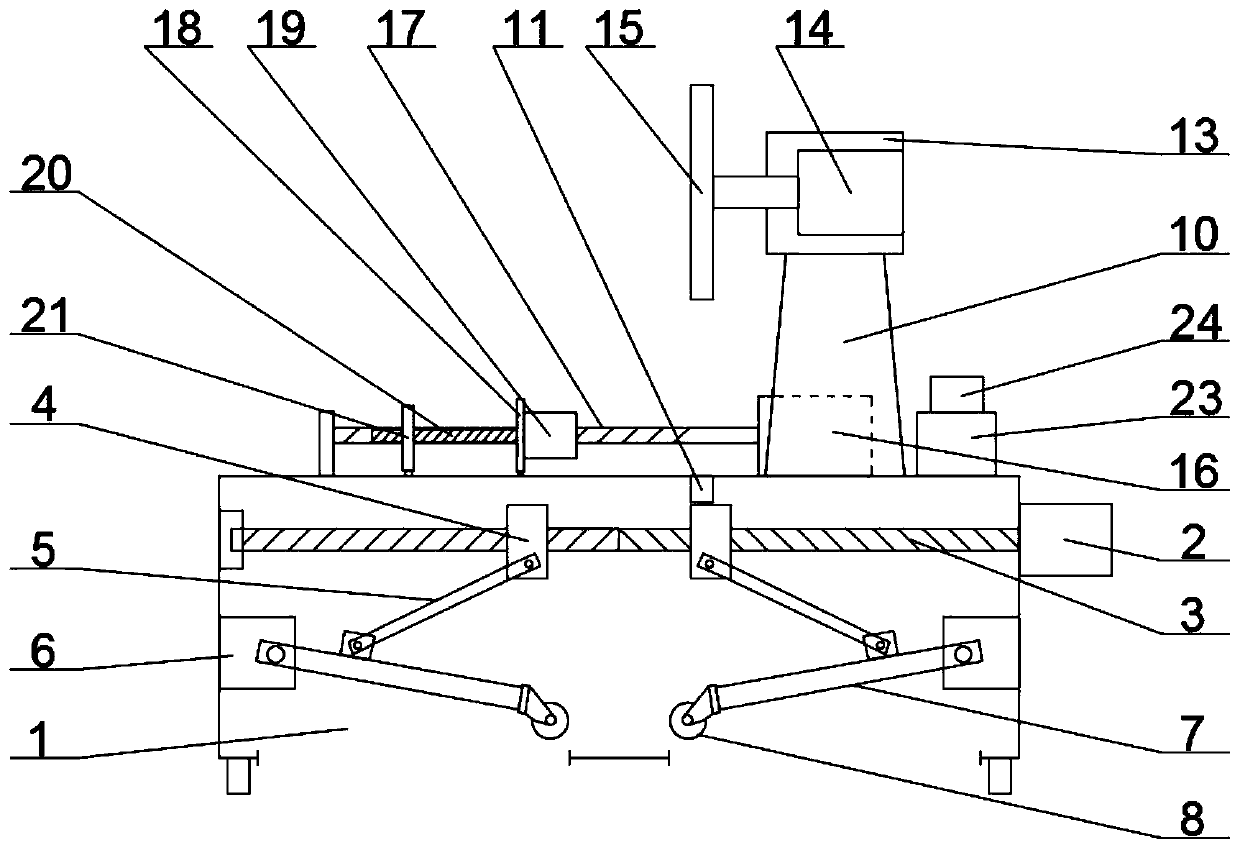

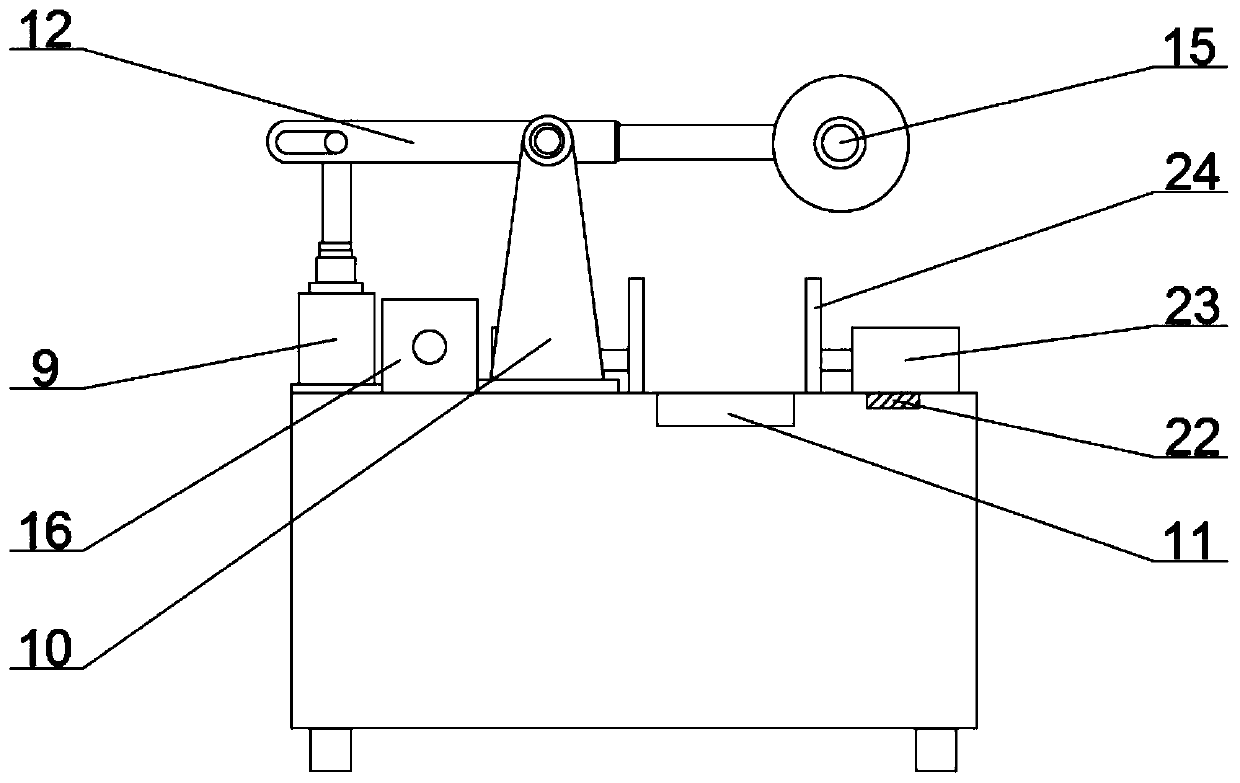

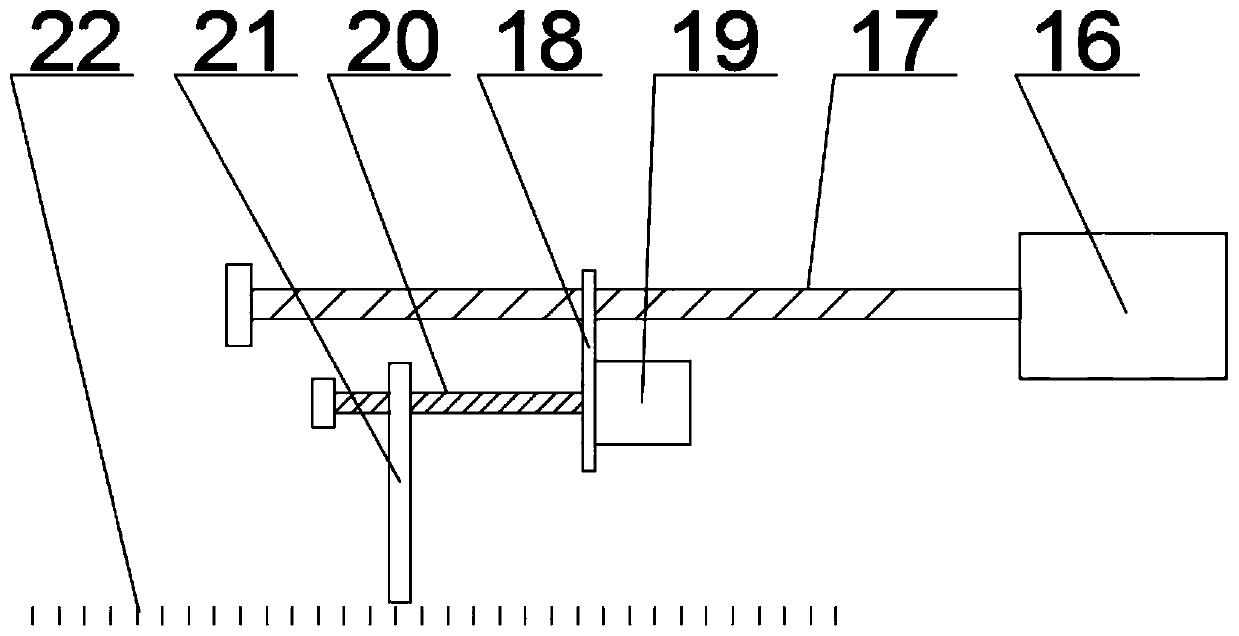

[0025] A cutting machine for fitness equipment production, comprising a base 1, the bottom surface of the base 1 is provided with legs, the outer side of the base 1 is provided with a motor D2 on the front and rear sides, and the output end of the motor D2 is provided with a penetrating base 1- The side wall and the double-rotational lifting screw 3 that is rotationally connected with the other side wall in the base 1, the two sides of the lifting screw 3 in the base 1 are screwed with a screw nut 4 and the bottom end of the screw nut 4 is hinged to connect Rod A5, the front side wall and the rear side wall in the base 1 are all provided with a support block 6 and the support block 6 is hinged with a connecting rod B7, the support block 6 is located below the lifting screw 3, and the connecting rod A5 is away from One end of the screw nut 4 is hinged with the connecting rod B7, and the end of the connecting rod B7 away from the support block 6 is provided with a moving wheel 8 ...

Embodiment 2

[0031]A cutting machine for fitness equipment production, comprising a base 1, the bottom surface of the base 1 is provided with legs, the outer side of the base 1 is provided with a motor D2 on the front and rear sides, and the output end of the motor D2 is provided with a penetrating base 1- The side wall and the double-rotational lifting screw 3 that is rotationally connected with the other side wall in the base 1, the two sides of the lifting screw 3 in the base 1 are screwed with a screw nut 4 and the bottom end of the screw nut 4 is hinged to connect Rod A5, the front side wall and the rear side wall in the base 1 are all provided with a support block 6 and the support block 6 is hinged with a connecting rod B7, the support block 6 is located below the lifting screw 3, and the connecting rod A5 is away from One end of the screw nut 4 is hinged with the connecting rod B7, and the end of the connecting rod B7 away from the support block 6 is provided with a moving wheel 8 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com