Preparation method for millimeter-grade polyacrylonitrile hollow microsphere

A technology of polyacrylonitrile and hollow microspheres, which is applied in the field of functional ceramics and can solve problems such as difficult preparation of polyacrylonitrile hollow microspheres, thinning of the composite fluid layer, and reduction of droplet size.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

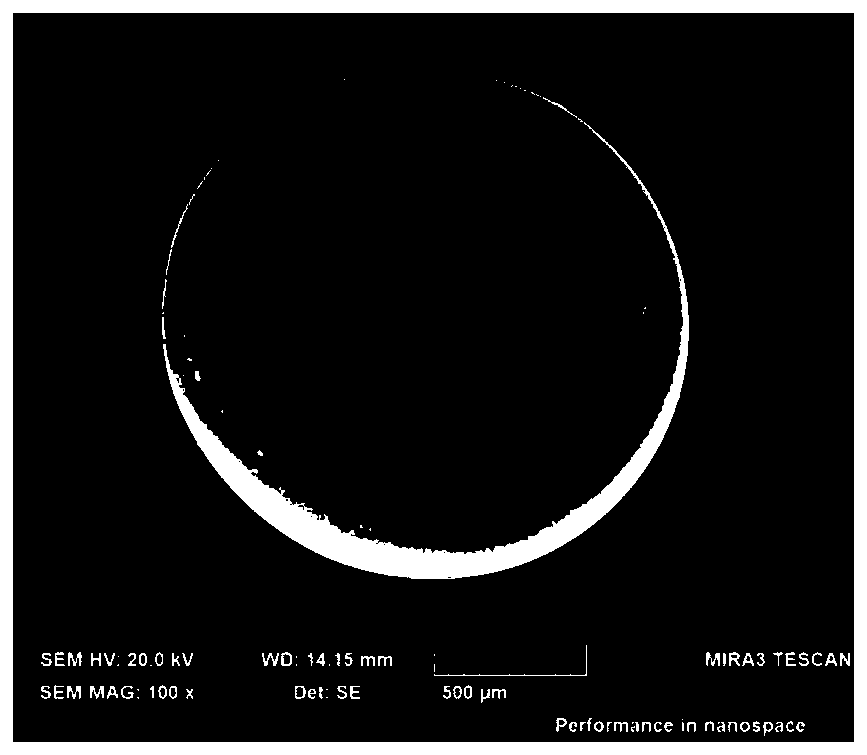

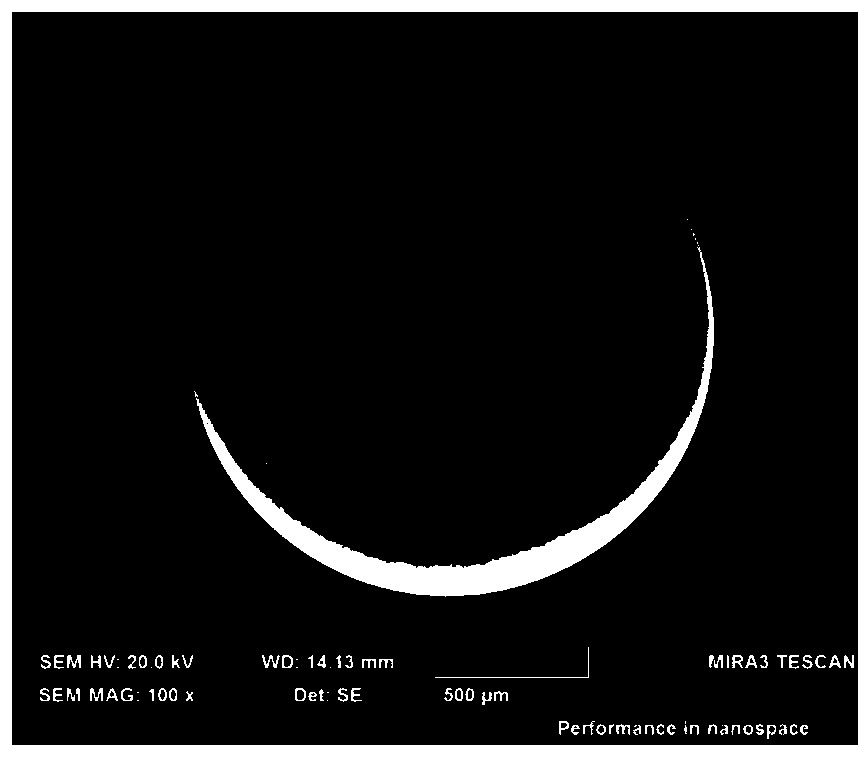

Image

Examples

preparation example Construction

[0040] The present invention provides a method for preparing millimeter-level polyacrylonitrile hollow microspheres, which includes the following steps:

[0041] S1: Use silicone oil with a viscosity of 450~550mPa.s as the first oil phase O 1 And the second oil phase O 2 ; Take the polyacrylonitrile solution as the water phase W; the first oil phase O 1 And the water phase W are respectively injected into the first syringe and the second syringe;

[0042] On the one hand, the use of high-viscosity silicone oil can meet the viscosity density matching between the phases. On the other hand, the high viscosity of the silicone oil is conducive to the better dispersion of the double droplets during the rotary steaming process and the adjustment of the sphericity. First oil phase O 1 Used to form O with water phase W 1 / W double drop, second oil phase O 2 Used as O during rotary evaporation 1 / W Double drop carrier.

[0043] The first syringe and the second syringe are syringes with a micro...

Embodiment 1

[0086] This embodiment provides a method for preparing millimeter-level polyacrylonitrile hollow microspheres, which includes the following steps:

[0087] S1: With a density of 0.9738g / cm 3 (25℃) Dimethicone with a viscosity of 500mPa.s is the first oil phase O 1 And the second oil phase O 2 ; Take the polyacrylonitrile solution with a molecular weight of 15w as the water phase W (the solvent is DMF, the mass fraction of polyacrylonitrile is 10wt%); the first oil phase O 1 And the water phase W are respectively injected into the first syringe and the second syringe;

[0088] S2: After removing the gas in the microchannel, set the advance rate of the first syringe and the second syringe to 4mL / h and 12mL / h, respectively, and advance the syringes in the order of the second syringe first and then the first syringe, until it can form a uniform Stable O 1 / W double drop, the O 1 / W Double droplets drop into the second oil phase O 2 Collect in a 550mL collection bottle;

[0089] S3: Let ...

Embodiment 2

[0097] This example provides a method for preparing millimeter-level polyacrylonitrile hollow microspheres. Compared with Example 1, the advancing rate of the first syringe in step S2 is changed from 4 mL / h to 6 mL / h, and the other steps are the same as in Example 1. .

[0098] The millimeter-level polyacrylonitrile hollow microspheres prepared in this example were characterized, measured and calculated. The average diameter, sphericity, concentricity, average wall thickness and uniformity of the wall thickness are shown in Table 3, which can be seen from the table. Because the internal phase silicone oil (the first oil phase O 1 ) As the flow rate increases, the diameter of the hollow microspheres increases to 1.8mm; however, the resulting O 1 / W The amount of PAN phase (PAN is polyacrylonitrile, PAN phase is water phase W) in the double droplet is reduced, and the wall thickness is reduced to 60μm, but still meets the ICF size index (International Functional Classification), and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com