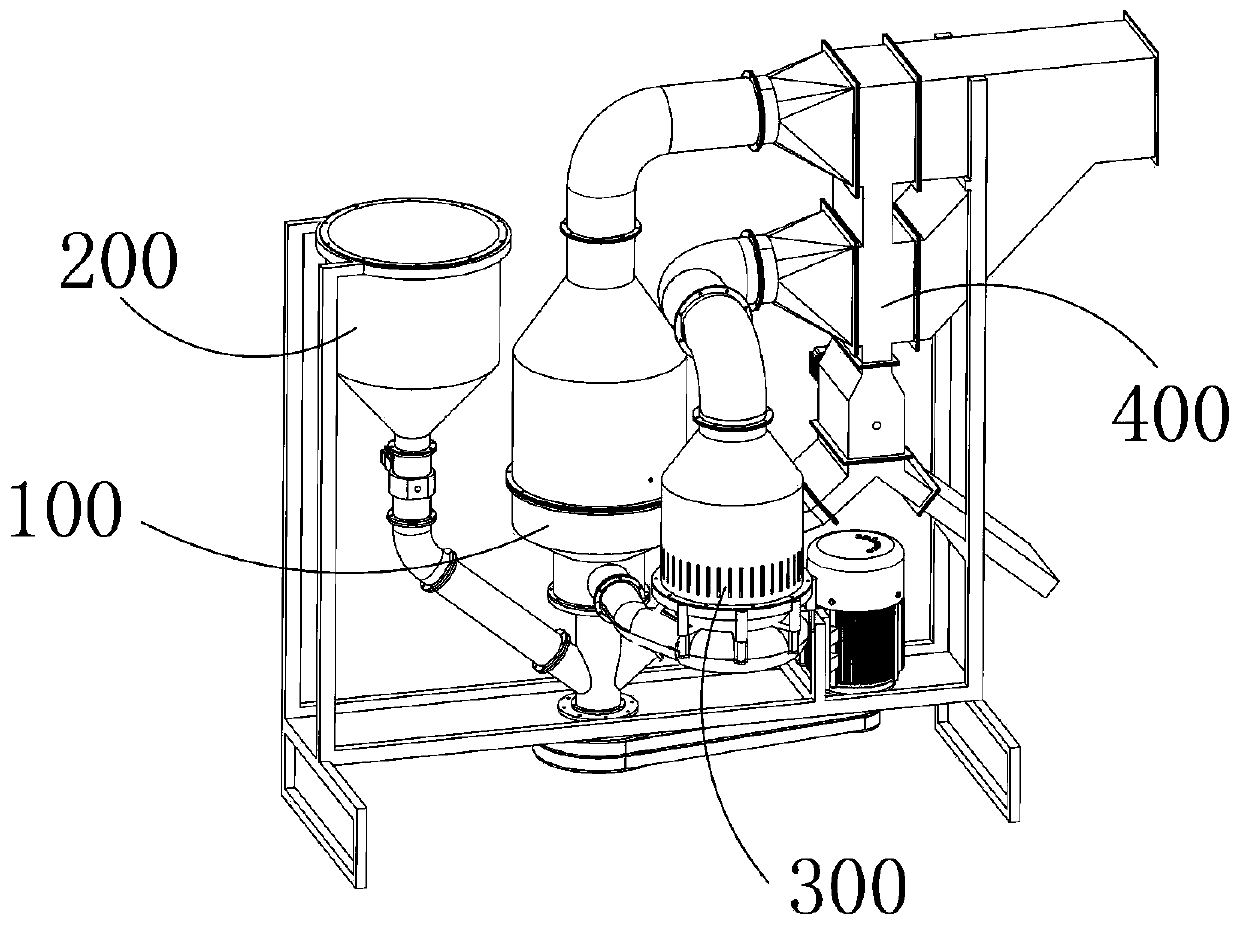

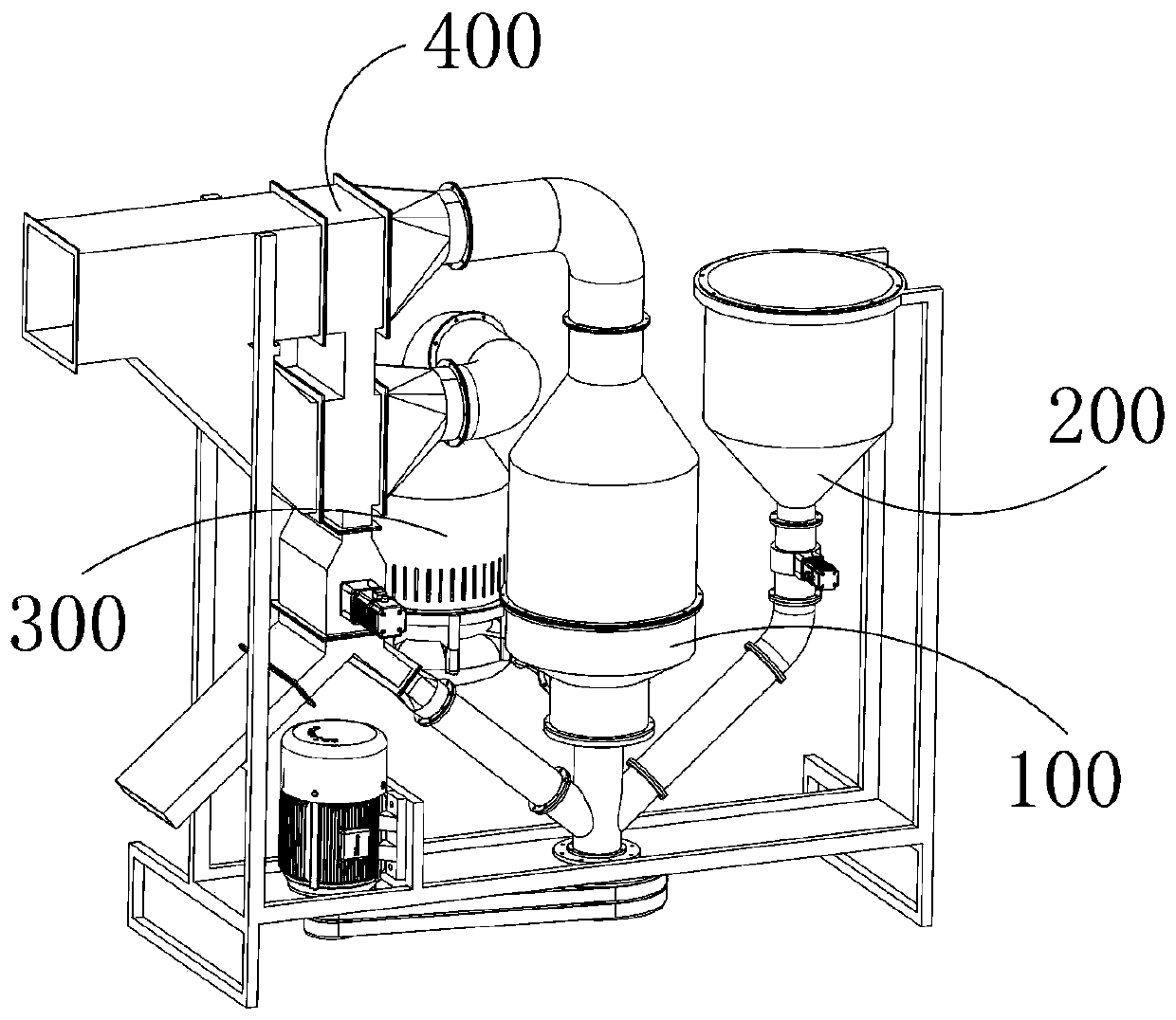

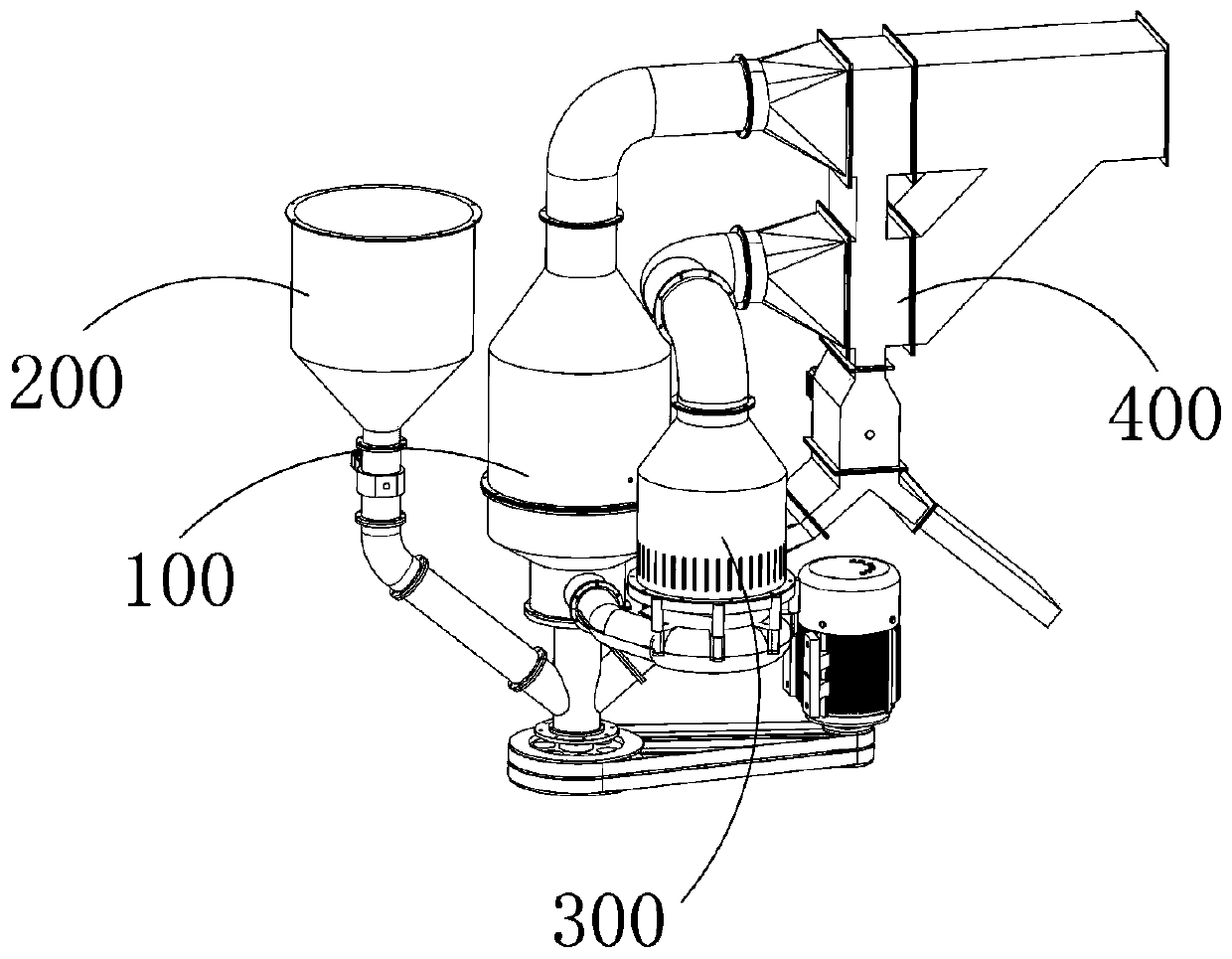

Internal circulation dryer applied to drying and dehumidifying rice and other grains

A dryer and internal circulation technology, which is applied in dryers, drying, grain drying, etc., can solve the problems of grain not being dried in time, affecting harvest, germination, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0061] The invention adopts the rotating hot air as the drying source and the suspension turning as the drying method to dry the grain. The advantage lies in that after the grain is transported into the drying tank, the hot air passes through the steady flow and cooperates with the wind direction changing part to make the hot air evenly disperse, Blowing into the drying tank in a rotating manner, so that the grain is dried in a suspended and flipped manner in the drying tank, and the drying efficiency and effect are better. The dried grain will be discharged by the first discharging mechanism through the circulating discharging mechanism. Cool down to avoid moisture in dry and high-temperature grains when they are stored in a subsequent closed environment. In addition, if the grains fail to meet the requirements after being dried once, the staff can control the discharge control gate to make the subsequent grains pass through. The return pipe is re-transported back to the turni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com