Soft Muti-ply tissue paper having surface deposited strengthening agent

A surface enhancement and surface deposition technology, which is applied in the direction of reinforcing agent addition, papermaking, adhesives, etc., can solve the problems of strengthening multi-piece products, without teaching sheet binder, and dry tensile strength does not increase significantly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

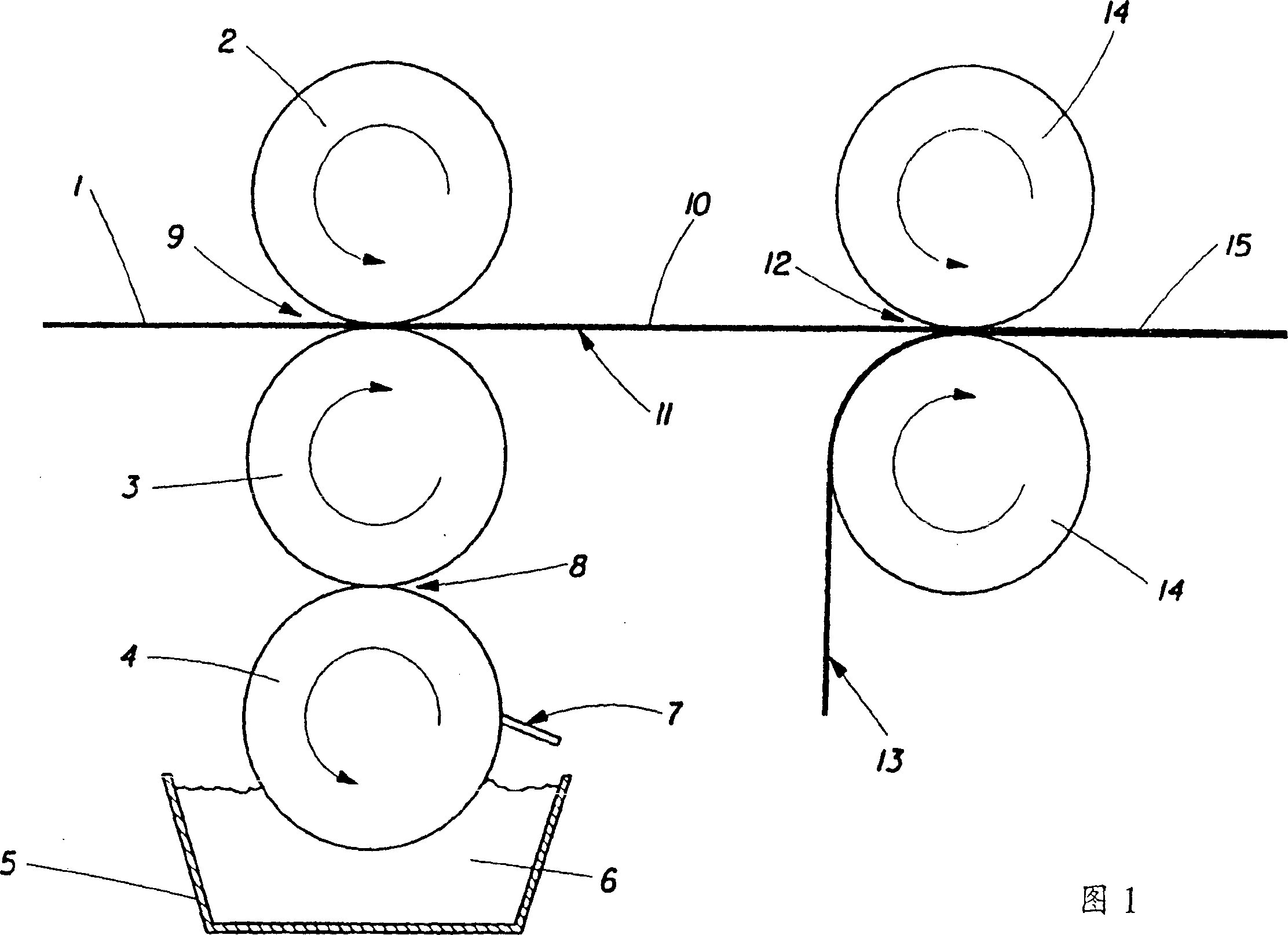

[0181] This example illustrates the use of a direct offset rotogravure printing machine to prepare a two-piece bath towel with a reinforcing agent on the inner surface.

[0182] The reagent used to prepare the fluidization enhancer is acrylic latex with a solid content of 45% (Rhoplex NW-2744F emulsion) obtained from Rohm & Hass Company in Philadelphia, Pennsylvania.

[0183] Mix 50% acrylic latex and 50% tap water to obtain a latex with a solid content of 23% to prepare a fluidized enhancer. Then, the fluidizing agent is put into the gravure printing groove, so that the fluidizing enhancer fills the recessed area of the rotary gravure cylinder.

[0184]The surface of the gravure cylinder is coated with alumina ceramics, and the recessed areas are carved into the alumina ceramics by laser technology. The recessed areas are hemispherical, each with a diameter of 55μ and a depth of about 228μ. The pattern of the recessed areas is hexagonal, and its occurrence rate is 137.8 per lin...

Embodiment 2

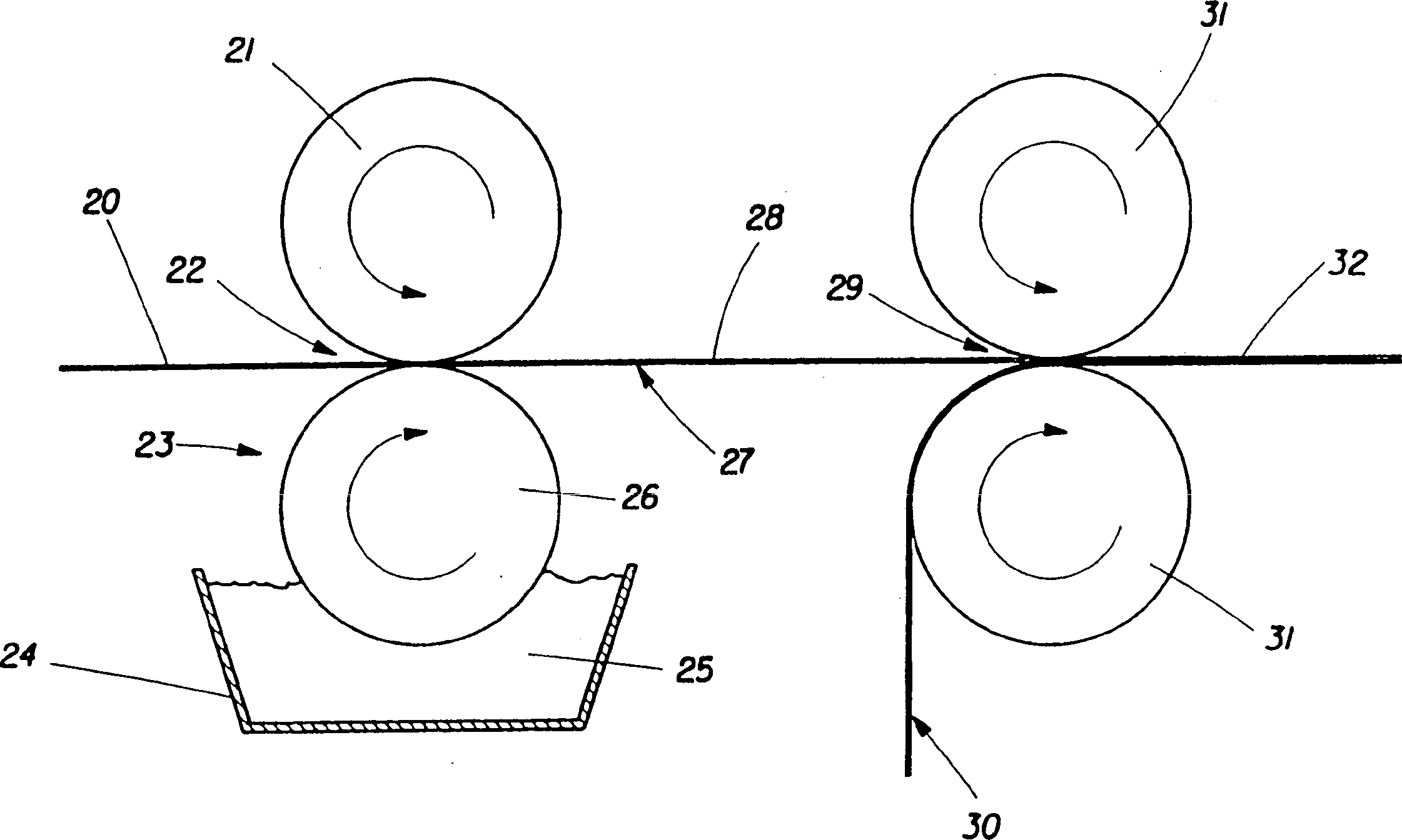

[0193] This example illustrates the use of a direct offset rotogravure printing machine to prepare two sheets of bath towel paper with a reinforcing agent on the inner surfaces of the two sheets.

[0194] The reagent used to prepare the fluidization enhancer is acrylic latex (Rhoplex NW-1845 emulsion) with a solid content of 44% obtained from Rohm&Hass Company in Philadelphia, Pennsylvania.

[0195] 50% acrylic latex and 50% tap water are mixed to obtain a latex with a solid content of 22% to prepare a fluidized enhancer. Then, the fluidization enhancer is put into the gravure groove, so that the fluidization enhancer fills the recessed area of the rotary gravure cylinder.

[0196] The surface of the gravure cylinder is coated with alumina ceramics, and the recessed areas are carved into the alumina ceramics by laser technology. The recessed areas are hemispherical, each with a diameter of 55μ and a depth of about 228μ. The pattern of the recessed areas is hexagonal, and its occ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com