Preparation method of lithium ion battery negative electrode material

A technology for lithium-ion batteries and negative electrode materials, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of low discharge specific capacity of ferric oxide, achieve cycle stability, increase charge and discharge capacity, and maintain structure The effect of completeness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

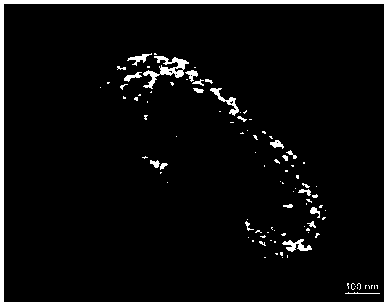

[0027] see Figure 1 to Figure 9 Shown, the preparation method of lithium ion battery negative electrode material of the present invention, at first prepare the ferric oxide (Fe2O3) of pure phase by hydrothermal reaction 2 o 3 ), then successively coat a layer of silicon dioxide and a carbon layer on the outer layer of ferric oxide, and then make the material form a yolk shell structure by etching away the silicon dioxide, and finally coat a layer of trioxide on the outer carbon layer Manganese forms Fe2O3 / C / Mn3MnO nanocomposites with a yolk-shell structure. While the carbon shell facilitates electron transport, the cavity between the carbon shell and the Fe2O3 core provides additional free space for structural strain relief, reducing shell damage caused by large volume changes, thereby maintaining structural integrity. The trimanganese tetraoxide nanomaterial in the carbon layer buffers the stress and strain and enhances the dynamic characteristics of the hybrid material th...

Embodiment 1

[0033] A preparation method for a negative electrode material of a lithium ion battery, comprising the steps of:

[0034] (1) Preparation of pure-phase ferric oxide powder by hydrothermal method: dissolve 6 grams of ferric chloride hexahydrate in 90 ml of water, then respectively 9.9569 grams of sodium acetate trihydrate and 2.9963 grams of hexadecyl trimethyl bromide Ammonium, 21 milliliters of ethylenediamine solution was added to the above solution, stirred for 10 minutes, placed in a reaction kettle, reacted at 200 degrees Celsius for 10 hours, cooled to room temperature, and centrifuged to obtain pure ferric oxide powder.

[0035] (2) Preparation of ferric oxide / silicon dioxide nanocomposite material: Take 0.93184 g of ferric oxide powder prepared in step (1) and dissolve in 560 ml of ethanol, add 2 ml of tetraethoxysilane, stir for 3 After 1 hour, add 10 milliliters of ammonia water and 40 milliliters of deionized water, stir for 4 hours, centrifuge, wash, and dry, then ...

Embodiment 2

[0039] A preparation method for a negative electrode material of a lithium ion battery, comprising the steps of:

[0040] (1) Preparation of pure-phase ferric oxide powder by hydrothermal method: dissolve 2 grams of ferric chloride hexahydrate in 50 ml of water, and then respectively 5 grams of sodium acetate trihydrate and 1 gram of hexadecyltrimethyl bromide Ammonium, 15 ml of ethylenediamine solution was added to the above solution, stirred for 5 minutes, placed in a reaction kettle, reacted at 150 degrees Celsius for 8 hours, cooled to room temperature, and centrifuged to obtain pure ferric oxide powder.

[0041] (2) Preparation of ferric oxide / silicon dioxide nanocomposite material: Take 0.5 g of ferric oxide powder prepared in step (1) and dissolve in 300 ml of ethanol, add 1.5 ml of tetraethoxysilane, stir for 2 After 1 hour, add 5 milliliters of ammonia water and 30 milliliters of deionized water, stir for 3 hours, centrifuge, wash and dry, and then treat in a tube fur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com