A design method of high-power intermediate frequency power transformer

A technology of power transformer and design method, applied in the direction of inductance/transformer/magnet manufacturing, design optimization/simulation, circuit, etc., can solve the problems of intermediate frequency transformer design and implementation without detailed reports and reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0112] Below in conjunction with accompanying drawing and specific embodiment the present invention will be further described as follows:

[0113] The optimization design process is shown in Figure 1(a) and Figure 1(b), including the flow chart of non-dominated sorting genetic algorithm with elitist strategy and the flow chart of objective function value calculation.

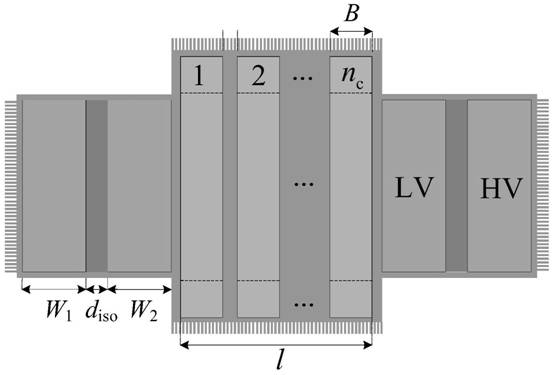

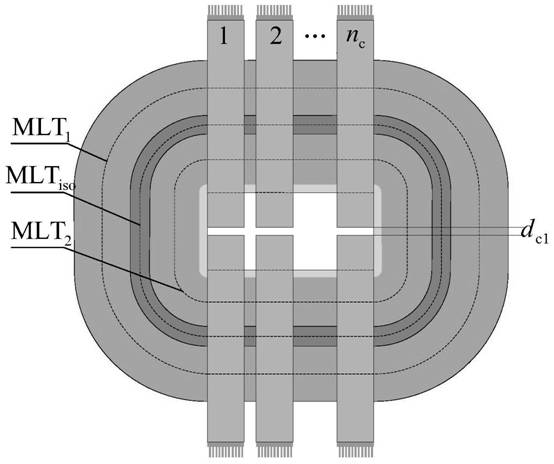

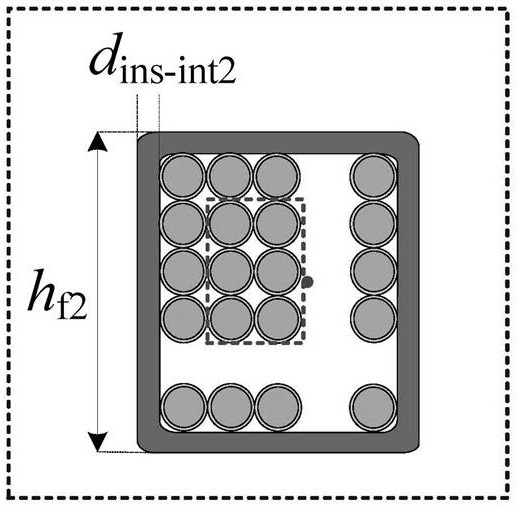

[0114] The schematic diagrams of the intermediate frequency power transformer are shown in Figure 2(a), Figure 2(b), Figure 2(c), Figure 2(d), and Figure 2(e). Litz wires are formed by stranding or intertwining insulated and independent conductors. Through these processes, the electromagnetic field can be evenly distributed in the cross-section of the wires, thereby effectively reducing the proximity effect of the wires. At the same time, the square Litz wire can ensure that the winding has a higher fill rate. Since the twisted structure of the square Litz wire can reduce the eddy current loss caused by the ski...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com