Method for determining formation condition of peptide Maillard intermediate by taking EGCG as tracer agent, peptide Maillard intermediate and application of peptide Maillard intermediate

An intermediate, Maillard reaction technology, applied in application, tobacco, food science, etc., can solve the problems of difficult qualitative and quantitative analysis of ARPs or HRPs, complex types of ARPs or HRPs, etc., and achieve strong storage stability and stable physical and chemical properties. , time-consuming effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

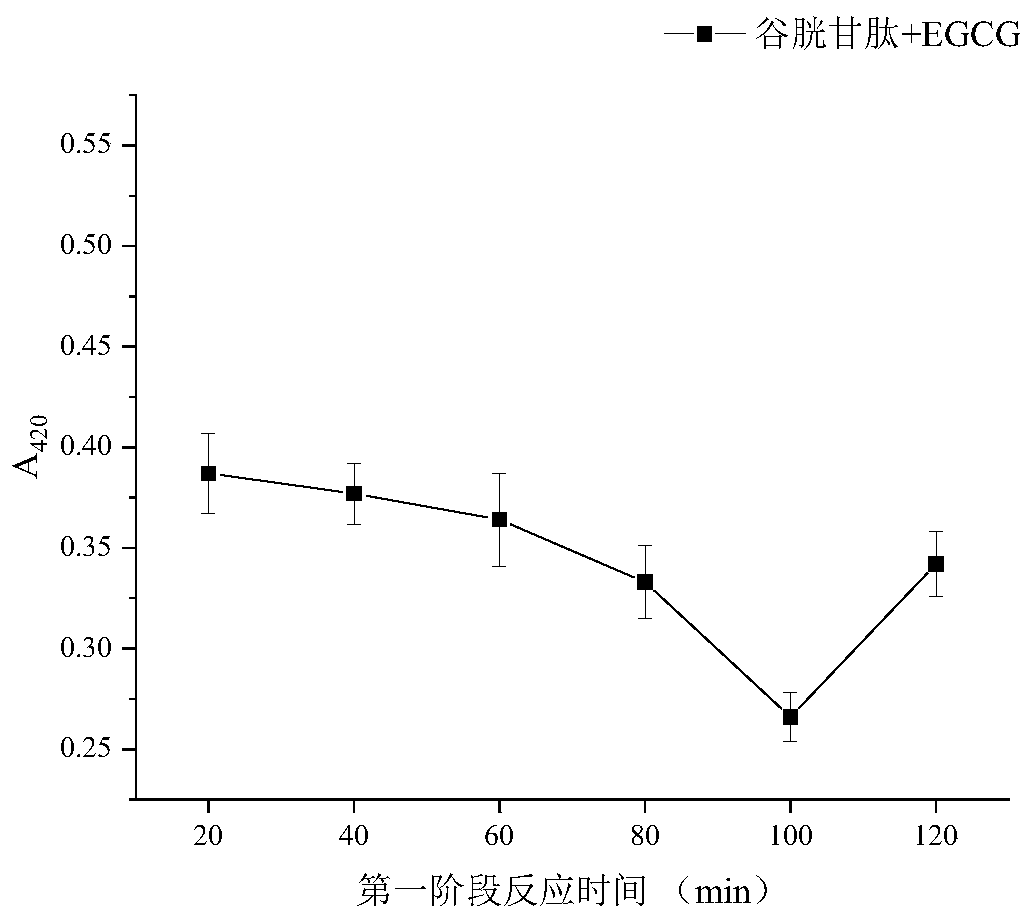

[0041] Dissolve 5kg of glutathione and 1kg of xylose in 500kg of water, carry out the low-temperature Maillard reaction at 80°C, take out the same volume of reaction solution at different time points of the reaction, cool in an ice bath to terminate the reaction, and adjust the pH of the solution to 7.5. Add 0.5-10wt% EGCG 0.25kg to each of the obtained reaction solutions, carry out high-temperature Maillard reaction at 120°C for 2 hours, and measure the wavelength of each part of variable-temperature Maillard reaction solutions at a wavelength of 420nm after cooling in an ice bath to terminate the reaction. Under the absorbance value, draw the relationship curve between the absorbance value and the low temperature reaction time, and the time point corresponding to the reaction solution with the lowest absorbance value is the formation time of the intermediate under the reaction conditions. Specific steps are as follows:

[0042] (1) First, 5kg of glutathione is dissolved in 5...

Embodiment 2

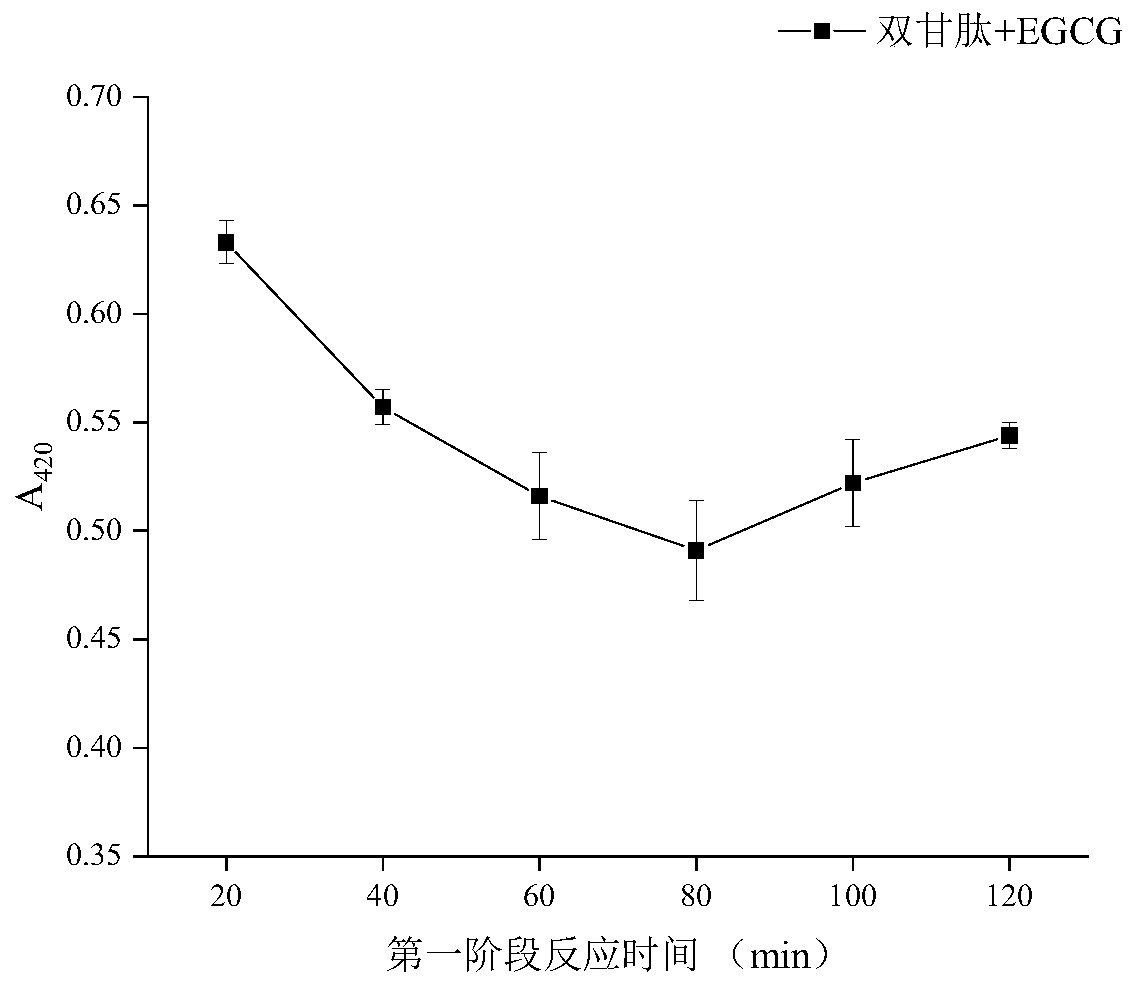

[0049] With embodiment 1. The difference is that the peptide is a diglycyl peptide. The absorbance values of 6 parts of high-temperature Maillard reaction solutions obtained at a wavelength of 420nm, and the relationship curves of corresponding time points are as follows: figure 2 shown. Depend on figure 2 It can be seen that the reaction time corresponding to the lowest absorbance point of the temperature-variable Maillard reaction solution is 80 minutes, that is, the critical time for the formation of ARP or HRP of the diglycyl peptide-xylose system in the aqueous phase is 80 minutes, and it can be determined that the peptides prepared under the corresponding conditions The optimal time for the reaction intermediate of Germany is 80min.

[0050] After low-temperature concentration and freeze-drying, the solid diglycyl peptide Maillard reaction intermediate can be obtained. Gained solid peptide Maillard reaction intermediate is analyzed with the HPLC-ELSD of embodimen...

Embodiment 3

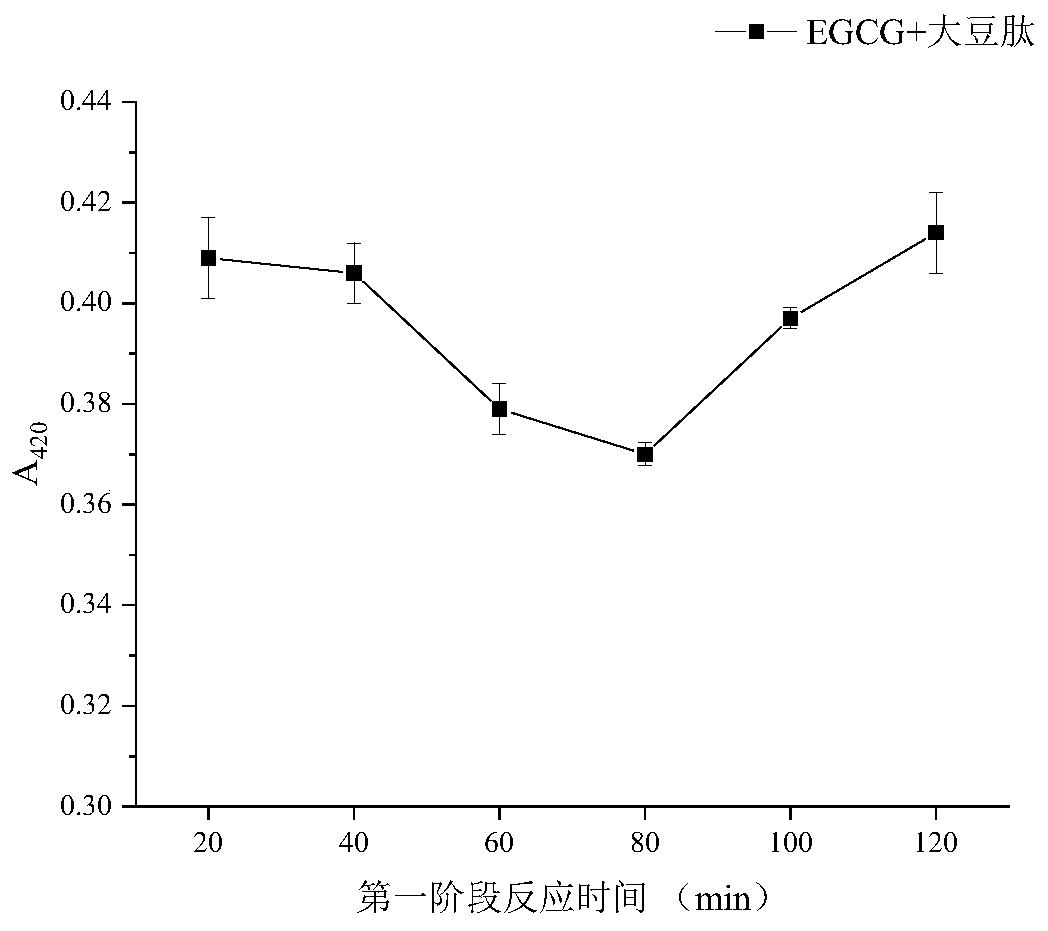

[0053] With embodiment 1. The difference is that the peptide is a soybean peptide, and the optimal time to prepare the peptide Maillard reaction intermediate under the corresponding conditions is determined to be 80min, see image 3 . The obtained product is a solid soybean peptide Maillard reaction intermediate. The solid soybean peptide Maillard reaction intermediate is added to food and tobacco, and as a result, the flavor of food and tobacco is obviously improved.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com