System and method for testing tensile strength distribution condition of explosive structural member

A technology for tensile strength and structural parts, which is applied in the field of test systems for the distribution of tensile strength of explosive structural parts, can solve the problems of long sample preparation period, long sample time, and high time cost, and achieve high test efficiency, The effect of less sample consumption and short preparation period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

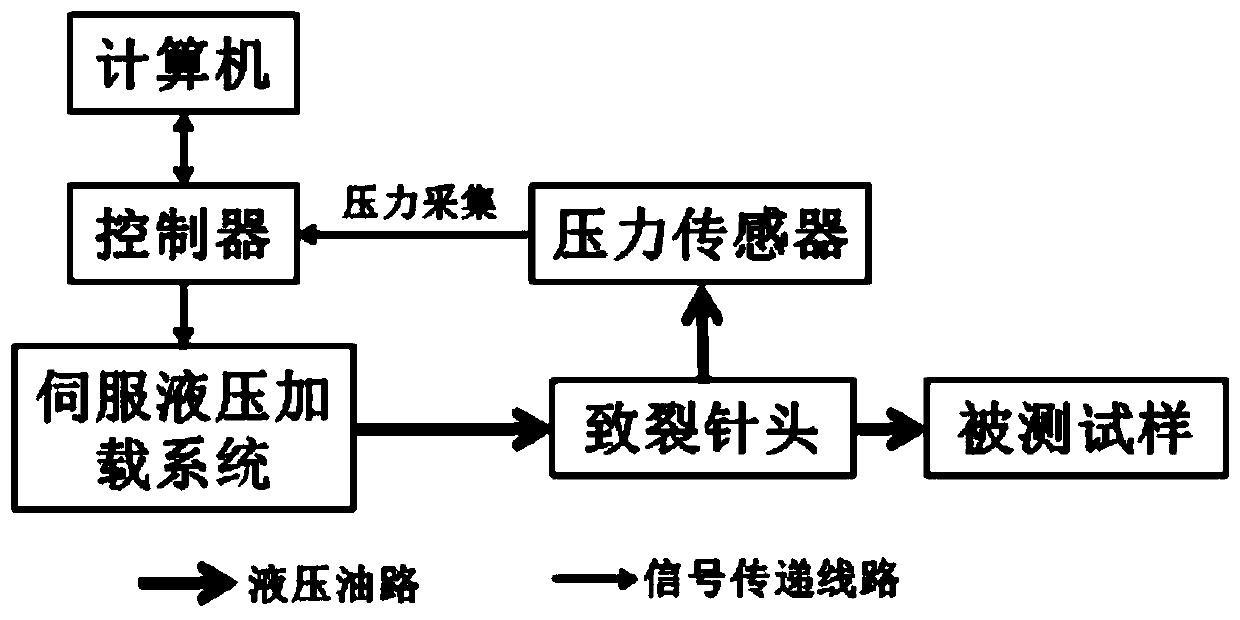

[0021] Such as figure 1 As shown, the present invention provides a test system for the distribution of tensile strength of explosive structural parts, the system includes a computer, a controller, a servo hydraulic loading system, a cracking needle and a pressure sensor, and the computer is used to pressurize The command is sent to the controller, and the controller is used to send the command to the servo hydraulic loading system, and the servo hydraulic loading system is used to apply pressure to the cracking needle, and the cracking needle acts on the explosive structure to cause cracking The pressure change at the needle is collected to the controller through the pressure sensor and fed back to the computer by the controller.

Embodiment 2

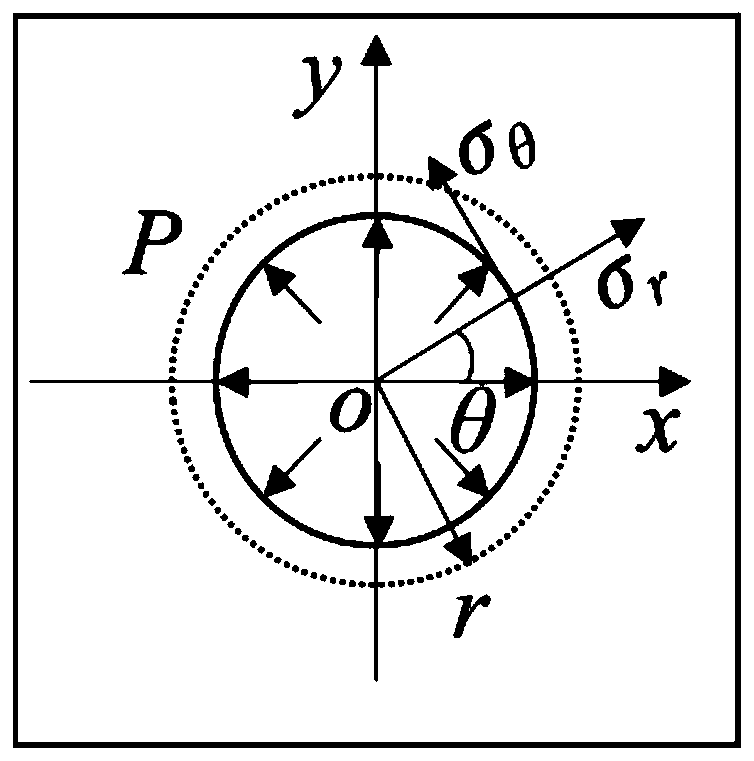

[0023] A method for testing the tensile strength distribution of explosive structural parts, specifically, first mechanically dissecting explosive structural parts into small pieces of arbitrary shape (satisfying that the effective size is greater than 1.5 times the aperture) and recording the position information of each piece of explosive, and then testing each piece Finally, the tensile strength data of each sample and the position information are combined to obtain the distribution of the tensile strength of the explosive structure. The testing process of each sample is as follows: First, a hole with a certain depth and the diameter of the cracking needle is drilled on the sample, and the cracking needle is put into the hole and the hole is sealed. The pressurization command is sent to the controller through the computer, and the controller then sends the command to the execution unit (servo hydraulic loading system), and the hydraulic oil is transmitted to the cracking nee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com