A paint spraying equipment for fire hoses containing high binding force functional paint

A technology for fire hoses and functional coatings, applied in mechanical equipment, pipes, hoses, etc., can solve problems such as corrosion of fire hoses, poor anti-corrosion performance of fire hoses, poor interface bonding effect, etc. Physicochemical properties and the effect of improving weather resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Based on the fire hose structure proposed in embodiment 1, wherein,

[0037] The rubber / resin composite material is a composition of natural rubber, EPDM rubber, and polyether polyol modified epoxy resin. The mass proportion of natural rubber is 0-20wt%, and the mass proportion of EPDM rubber is 65- 80 wt%, and the mass proportion of the polyether polyol modified epoxy resin is 10-30 wt%.

[0038] The warp thread for fiber skeleton layer blending is made of polyamide fiber and brucite fiber with a mass ratio of 1:0.6, the weft thread is made of polypropylene fiber and brucite fiber with a mass ratio of 1:0.75, and the warp composite fiber is loaded There are basalt chopped fibers with a mass percentage of 6-10 wt%, and talcum powder with a mass percentage of 2-8 wt% loaded on the weft composite fiber filaments.

[0039] The mass percentages of silicon micropowder, magnesium hydroxide, desulfurized rubber powder and EPDM rubber in the external protective layer are 2-7wt...

Embodiment 2

[0042] Based on the fire hose structure and material proposed in embodiment 1 and embodiment 2, a kind of paint spraying equipment is further provided, as follows:

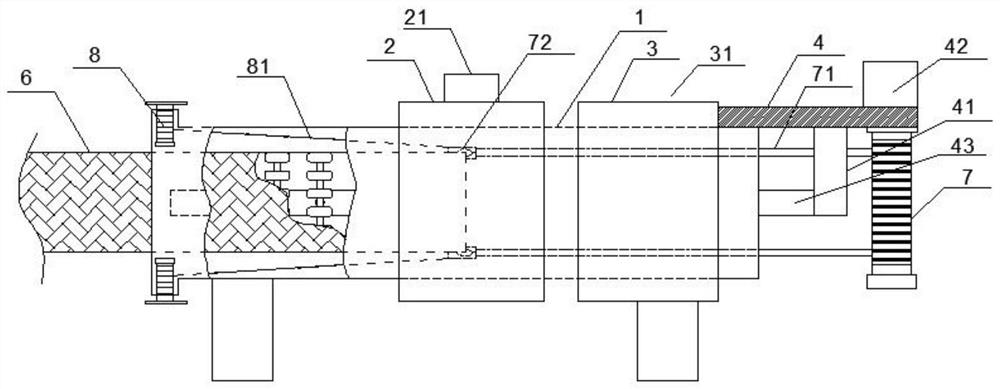

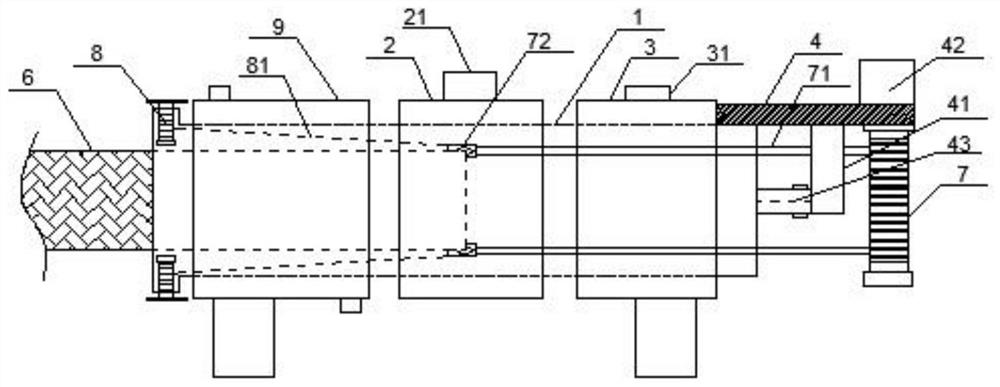

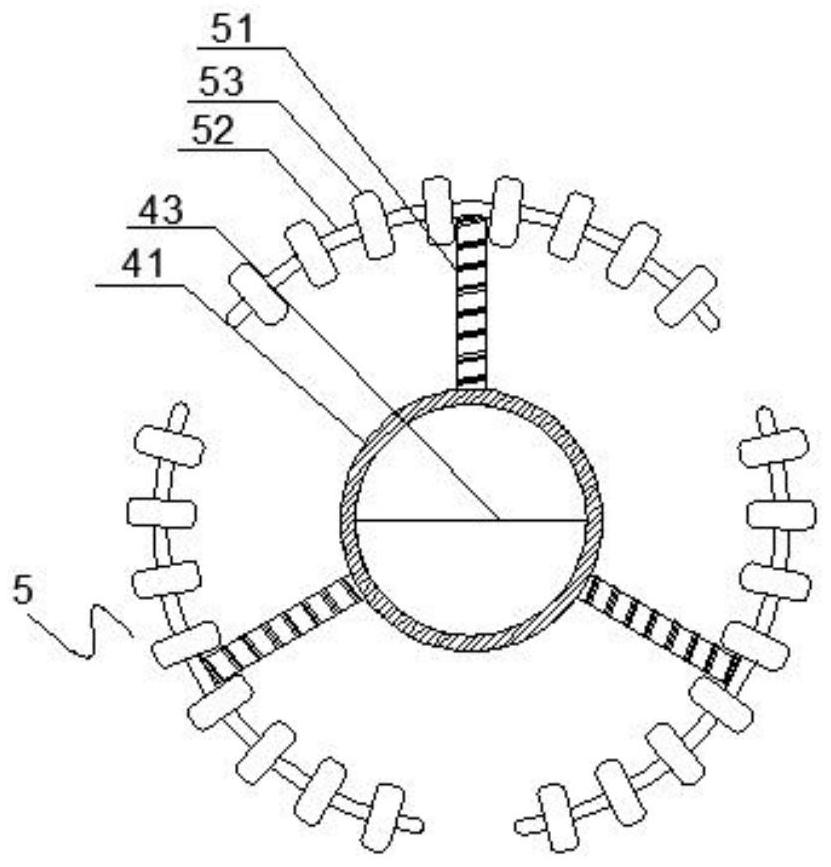

[0043] A kind of paint spraying equipment, used for the preparation of the above-mentioned fire-fighting hose containing high-binding force functional paint, including a conveying cylinder 1 and a spraying chamber 2 and a drying chamber 3 arranged in the direction of the long axis of the conveying cylinder 1 in sequence, the spraying chamber 2 The outer wall is connected to the paint feed port 21, and the spraying chamber 2 is connected to the inner cavity of the transmission cylinder 1. There are several ring-shaped spray gun heads (not shown in the figure) for spraying on the outer surface of the fire hose in the transmission cylinder 1. Paint, the outer wall of the drying chamber 3 communicates with the airflow inlet 31, and the drying chamber 3 communicates with the inner cavity of the transmission cylinder 1 a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com