LED UV curing permanent antistatic hardened coating for TAC film

A hard coating and antistatic technology, which is applied in the field of LEDUV curing permanent antistatic hard coating, can solve the problems of easy generation of static electricity, easy deformation of TAC, low thermal effect, etc., and achieve rapid curing, low price and light color Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~5 and comparative example 1~2

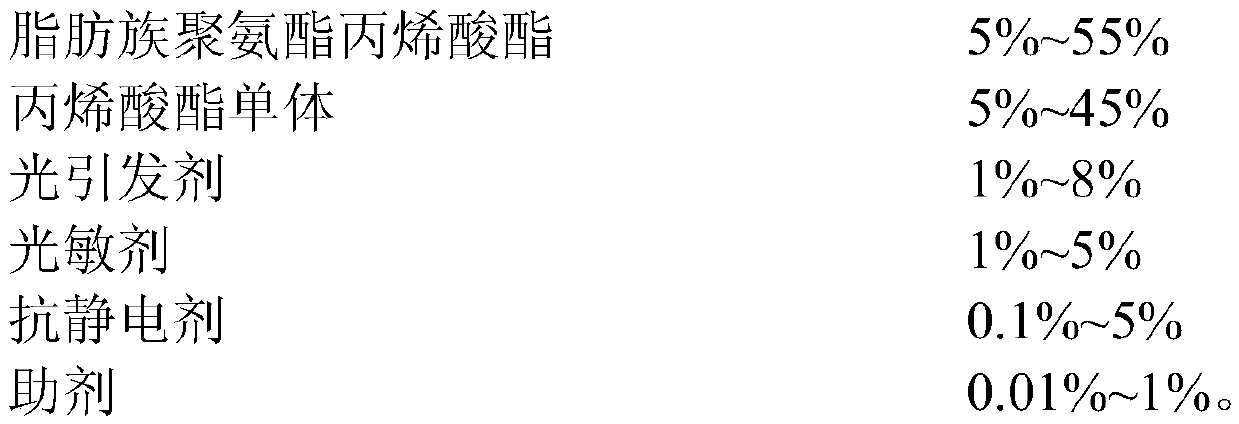

[0035] Add high-functionality aliphatic urethane acrylate, alicyclic monofunctional acrylate monomer, photoinitiator, photosensitizer, antistatic agent and auxiliary agent sequentially according to the ratio shown in Table 1.

[0036] CN8885 obtained from Sartomer Company was used as acrylate oligomer A1;

[0037] 6195 obtained from Changxing Company was used as acrylate oligomer A2;

[0038] Em265 obtained from Changxing Company was used as acrylate monomer B1;

[0039] IBOA obtained from Akeli Company was used as acrylate monomer B2;

[0040] TPO obtained from Double Bond Corporation was used as photoinitiator C1;

[0041] 907 obtained from the market is used as photoinitiator C2;

[0042] Commercially available ITX was used as photosensitizer C3;

[0043] The 1-ethyl-3-methylimidazole bis-trifluoromethylsulfonimide salt obtained from the market is used as antistatic agent D;

[0044] Tego 432 obtained from Evonik was used as leveling agent E.

[0045] Formulation tabl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com