Method for catalyzing veratryl alcohol to convert into 3,4-dimethoxytoluene

A technology of dimethoxytoluene and veratrol, applied in chemical instruments and methods, preparation of organic compounds, physical/chemical process catalysts, etc., can solve the problems of less research on the hydrodeoxygenation and hydrogenation of veratrol, Achieve the effects of high conversion rate, good selectivity and safe operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

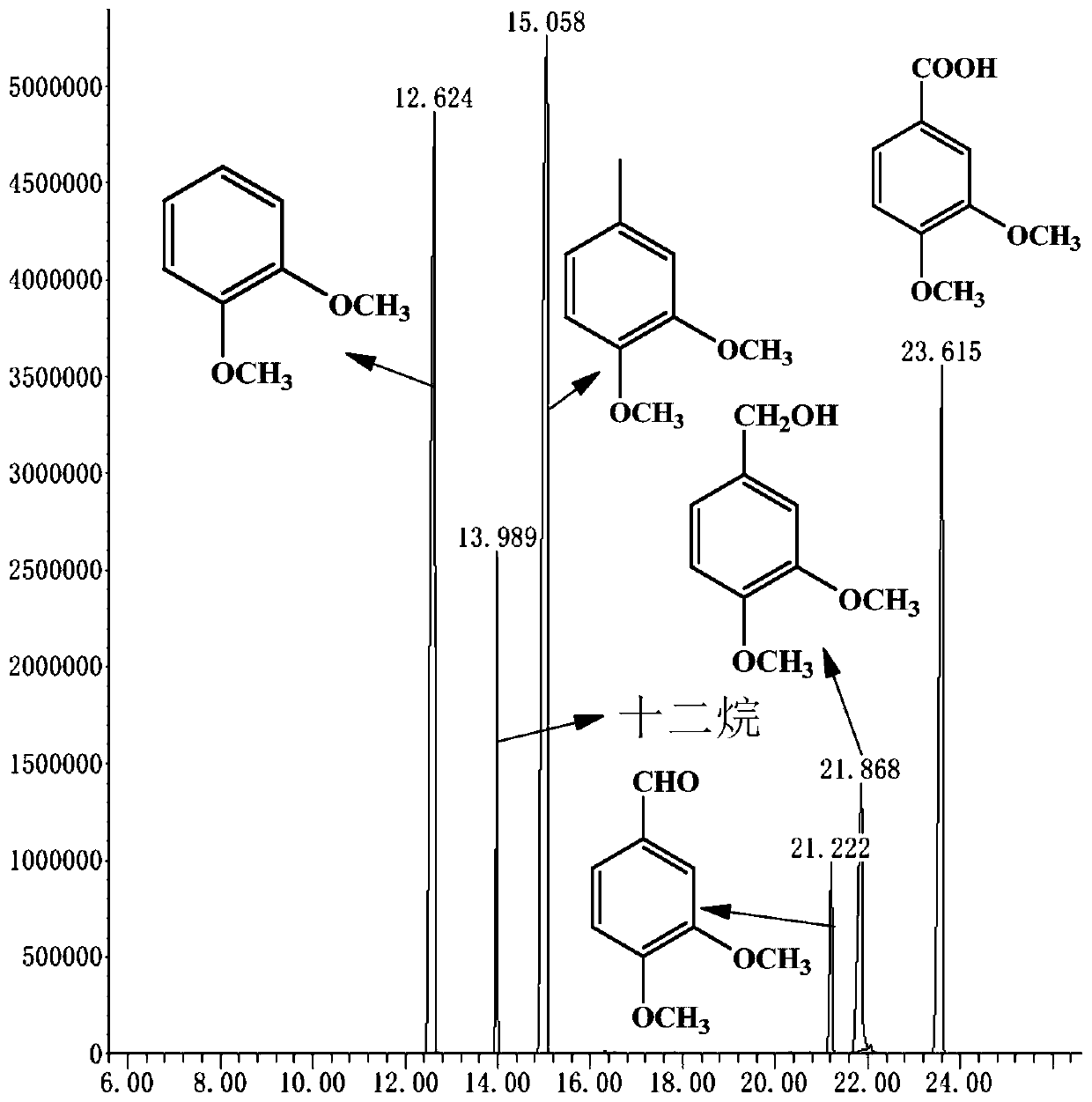

Image

Examples

Embodiment 1

[0033] (1) Using 10 g of biomass resource chitosan as a carbon source, roasting at 600 °C for 8 hours to prepare CN 0.28 ; Make CN by ultrasonic disperser 0.28 Uniformly dispersed in water; using 0.2 mmol palladium acetate as palladium source, it was uniformly dispersed in CN 0.28 Suspension to obtain a mixture; use 300W of ultraviolet light to carry out photocatalytic reduction of inactive palladium for 4h to obtain CN with active palladium 0.28 Suspension; the suspension is separated by centrifugation, and the solid phase is vacuum-dried in a vacuum desiccator to obtain 2wt% palladium Pd / CN 0.28 . Weigh 0.05g 2wt% palladium Pd / CN 0.28 As a catalyst, after mixing 2mL of veratrol in the reaction vessel, add 38mL of isopropanol as solvent and hydrogen donor;

[0034] (2) Disperse the reactor in an ultrasonic disperser for 1 minute, replace the air in the reactor with argon for 5 times, tighten the air valve, set the reaction temperature to 180°C, the reaction pressure to 1....

Embodiment 2

[0038] (1) Using 10 g of biomass resource chitosan as a carbon source, roasting at 600 °C for 8 hours to prepare CN 0.28 ; Make CN by ultrasonic disperser 0.28 Uniformly dispersed in water; using 0.2 mmol palladium acetate as palladium source, it was uniformly dispersed in CN 0.28 Suspension to obtain a mixture; use 300W ultraviolet light to carry out photocatalytic reduction of inactive palladium for 4h to obtain CN loaded with active palladium 0.28 Suspension; the suspension is separated by centrifugation, and the solid phase is vacuum-dried in a vacuum desiccator to obtain the Pd / CN of 5 wt% palladium 0.28 . Weigh 0.05 g of 5 wt% palladium in Pd / CN 0.28As a catalyst, after mixing 2mL of veratrol in the reaction vessel, add 38mL of isopropanol as solvent and hydrogen donor;

[0039] (2) Disperse the reactor in an ultrasonic disperser for 1 minute, replace the air in the reactor with argon 5 times, tighten the air valve, set the reaction temperature to 230°C, the reaction...

Embodiment 3

[0043] (1) Using 10 g of biomass resource chitosan as a carbon source, roasting at 600 °C for 8 h to prepare CN 0.28 ; Make CN by ultrasonic disperser 0.28 Uniformly dispersed in water; using 0.2 mmol palladium acetate as palladium source, it was uniformly dispersed in CN 0.28 Suspension to obtain a mixture; use 300W ultraviolet light to carry out photocatalytic reduction of inactive palladium for 4h to obtain CN loaded with active palladium 0.28 suspension; the suspension is separated by centrifugation, and the solid phase is vacuum-dried in a vacuum desiccator to obtain the Pd / CN of 10 wt% palladium 0.28 . Weigh 0.05 g of 10 wt% palladium in Pd / CN 0.28 As a catalyst, after mixing 2mL of veratrol in the reaction vessel, add 38mL of isopropanol as solvent and hydrogen donor;

[0044] (2) Disperse the reactor in an ultrasonic disperser for 1 minute, replace the air in the reactor with argon for 5 times, tighten the air valve, set the reaction temperature to 280°C, the react...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com