Power busbar

A technology for power busbars and busbars, applied in circuits, conductive connections, electrical components, etc., can solve problems such as breakdown, reduce the insulation performance of power porcelain bottles, and safety hazards, reduce temperature differences, ensure safe and normal work, and prevent serious problems. damage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

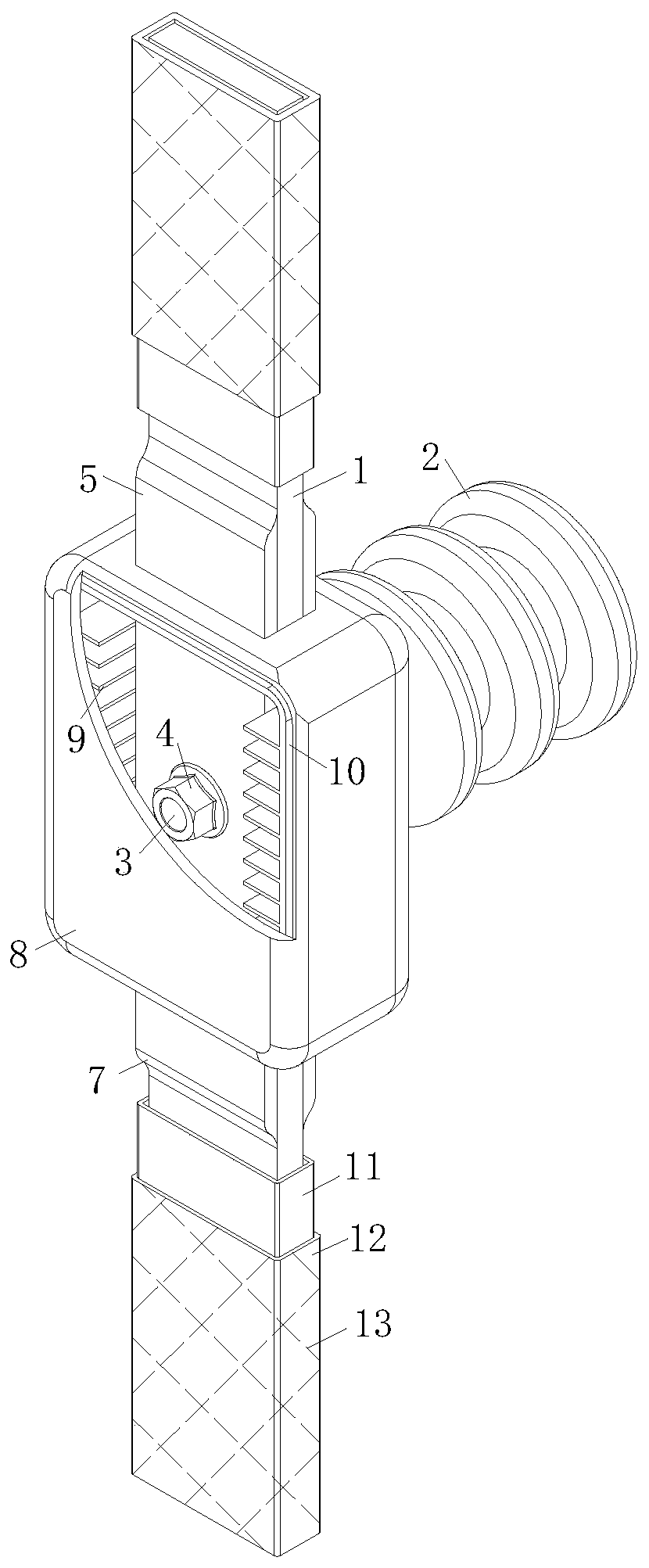

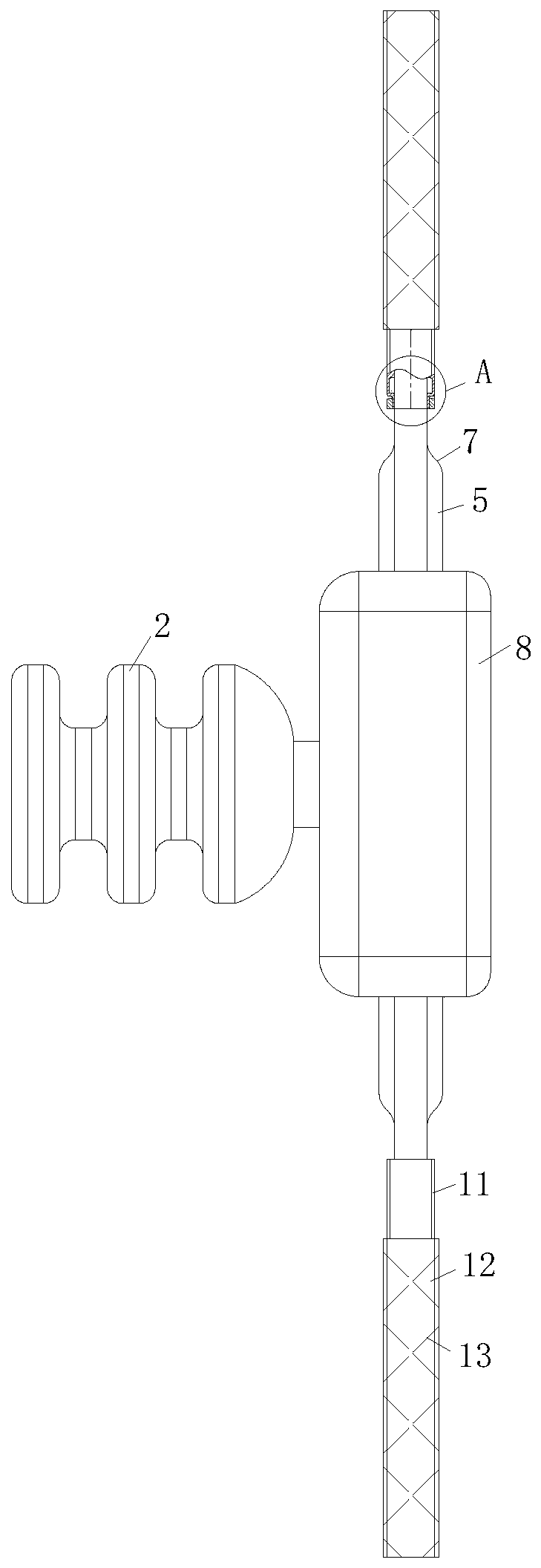

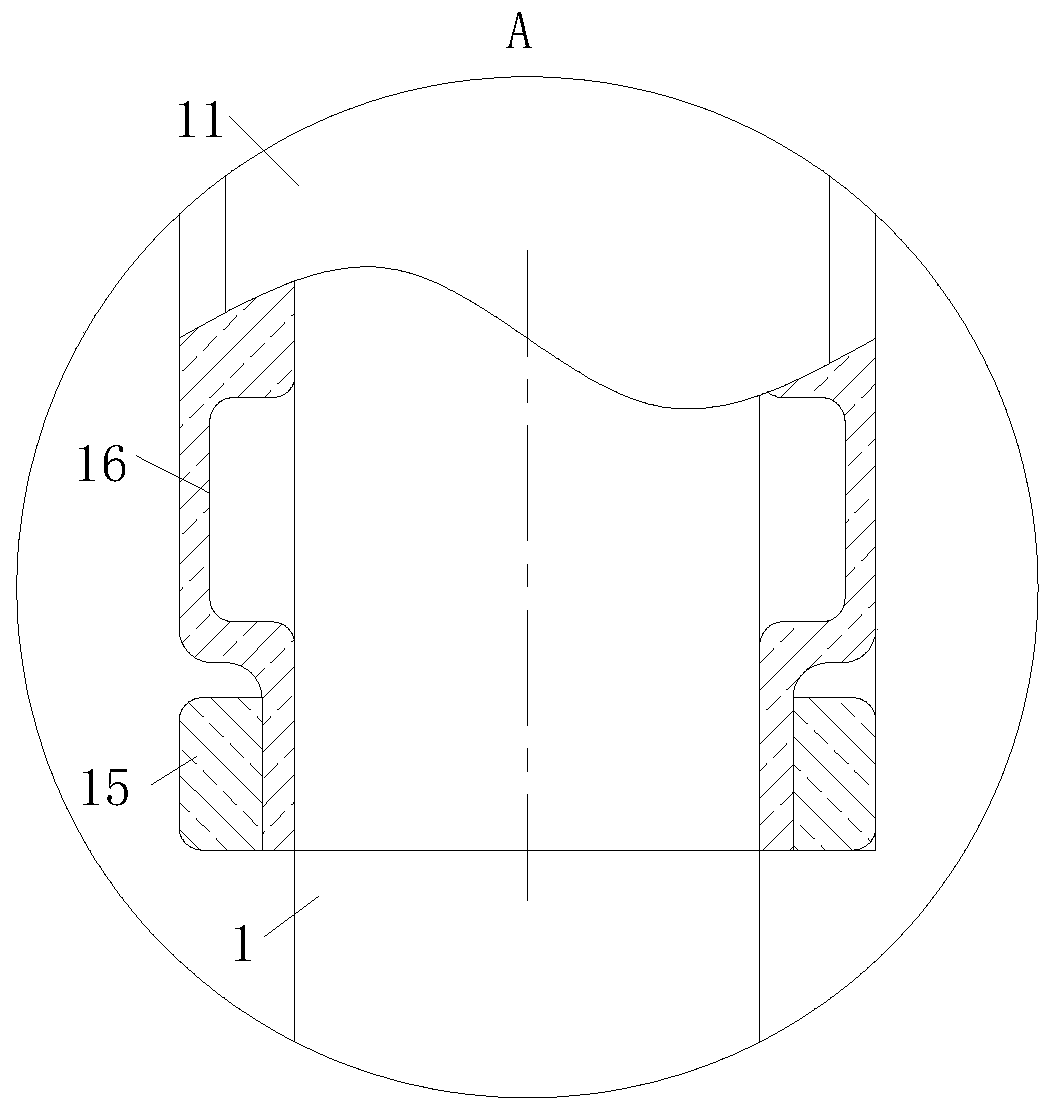

[0024] As an embodiment of the present invention, the two ends of the copper plate 5 are provided with arc chamfers 7, and the arc chamfers 7 are used to reduce the discharge at the tip of the copper plate 5; and sharp corners, so that the busbar body 1 can reduce the tip discharge phenomenon at both ends of the copper plate 5 when delivering high-voltage or ultra-high voltage current, further ensure that the busbar body 1 has good insulation performance, and prevent the tip discharge from penetrating the air. The substation equipment is seriously damaged, and the service life of the busbar body 1 is increased.

[0025] As an embodiment of the present invention, an arc extinguishing cover 8 is sleeved in the middle of the copper plate 5 , and a set of insulating grids 9 are arranged on the inner wall of the arc extinguishing cover 8 . Discharge at the tip; since the busbar body 1 is fixed with the power porcelain bottle 2 by fastening bolts and nuts 4, and the nut 4 has a hexa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com