Power supply device and manufacturing method of printed circuit board winding

A technology for printed circuit boards and power supply devices, applied in the directions of printed circuits, printed circuits, printed circuit components, etc., can solve the problems of reducing the on-resistance of conductive windings, increasing the conductive layer inside the PCB, and unable to solve the on-resistance, etc. The effect of increasing the conduction cross-sectional area, improving the heat dissipation efficiency and reducing the skin effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

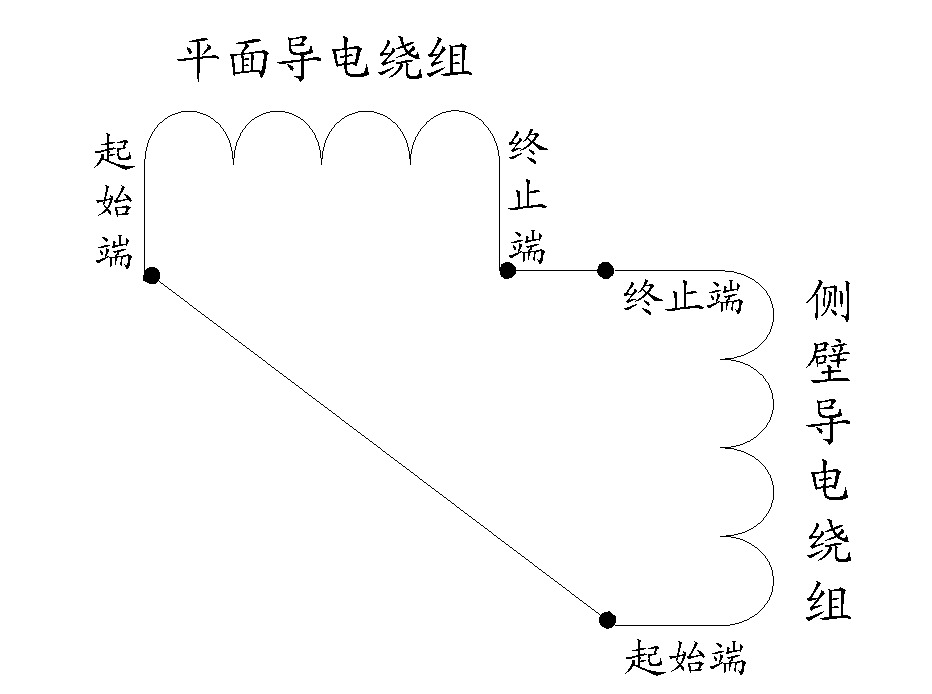

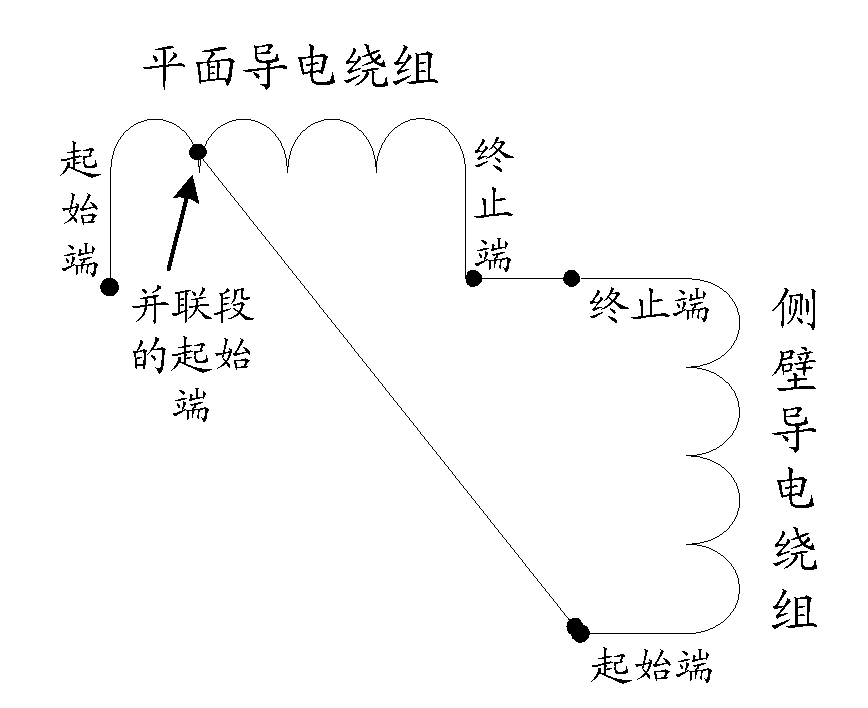

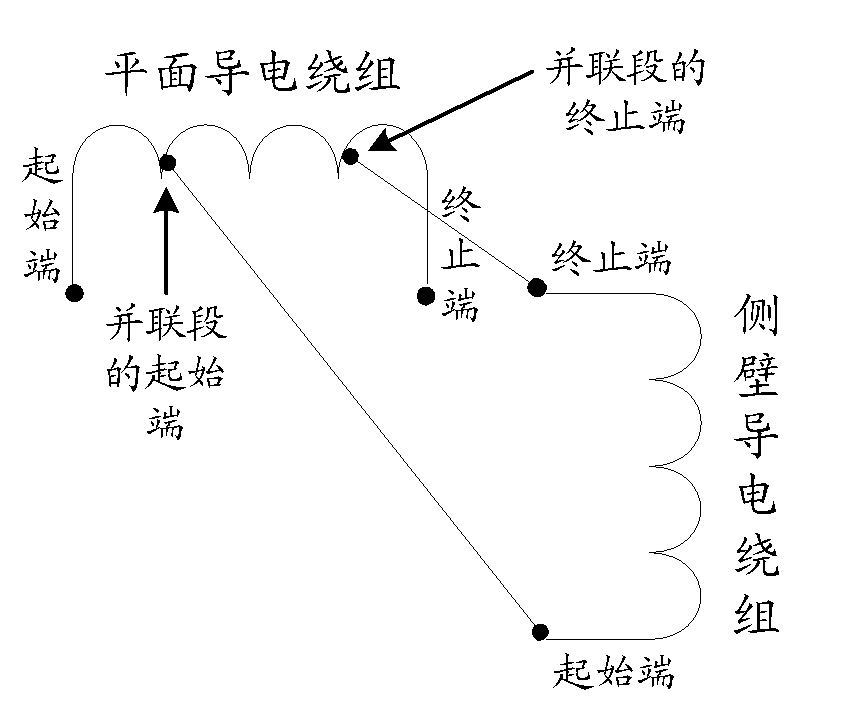

[0054]An embodiment of the power supply device of the present invention may include: at least one printed circuit board, at least one magnetic core, and at least one group of semiconductor conversion units; wherein, a magnetic core slot for installing a magnetic core is opened on the printed circuit board; the printed circuit board The slot side wall of at least one magnetic core slot of the circuit board is provided with a side wall conductive winding for cooperating with the magnetic core installed in the magnetic core slot for electromagnetic transformation, wherein the side wall conductive winding is attached to the magnetic core slot Part or all of the surface of the side wall of the slot; the semiconductor conversion unit is used to cooperate with the magnetic core and the conductive winding on the side wall to convert electric energy.

[0055] Wherein, the printed circuit board of the power supply device may be a single-layer board, a double-layer board or a multi-layer ...

Embodiment 2

[0069] In order to better understand the technical solutions of the embodiments of the present invention, the structure of a power supply device including a 4-layer PCB is taken as an example below to describe as an example. It can be understood that the scene where the power supply device includes a double-layer board or a PCB with other layers can be analogized.

[0070] see Figure 5 , the power supply device provided by the embodiment of the present invention may include:

[0071] A printed circuit board 100, two pairs of magnetic cores 201 and 202, a semiconductor conversion unit 301, and the like.

[0072] Among them, the printed circuit board 100 is provided with a magnetic core groove for installing the magnetic core, and the two pairs of magnetic cores 201 and 202 are buckled on the magnetic core groove of the printed circuit board 100 respectively; the semiconductor conversion unit 301 is welded on (or through other electrical connection mode) on the printed circui...

Embodiment 3

[0091] The embodiment of the present invention also provides a PCB winding manufacturing method, which may include: milling slots on the printed circuit board where the magnetic core slots of the sidewall conductive windings need to be arranged to form slots that require electroplating; The wall is electroplated to form a side wall conductive winding; wherein, the side surface of the side wall conductive winding is recessed or flush with the notch edge of the magnetic slot; the side wall conductive winding is used to connect with the magnetic core installed in the magnetic core slot Cooperate with electromagnetic transformation.

[0092] If the edge of the magnetic core slot is completely overlapped with the conductive winding on the side wall (that is, it is fully covered in the plane direction of the magnetic core slot), the magnetic core slot will be formed after electroplating; Complete coincidence (that is, incomplete coverage in the plane direction of the magnetic core s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com