Reflection type laser illumination system

A laser lighting and reflective technology, applied in the field of lighting systems, can solve the problems of very high processing precision of structural parts, great influence on beam installation accuracy, difficulty in applying high-power lighting, etc., and achieve long life of laser lighting, laser light The effect of high efficiency utilization and simple wavelength conversion device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

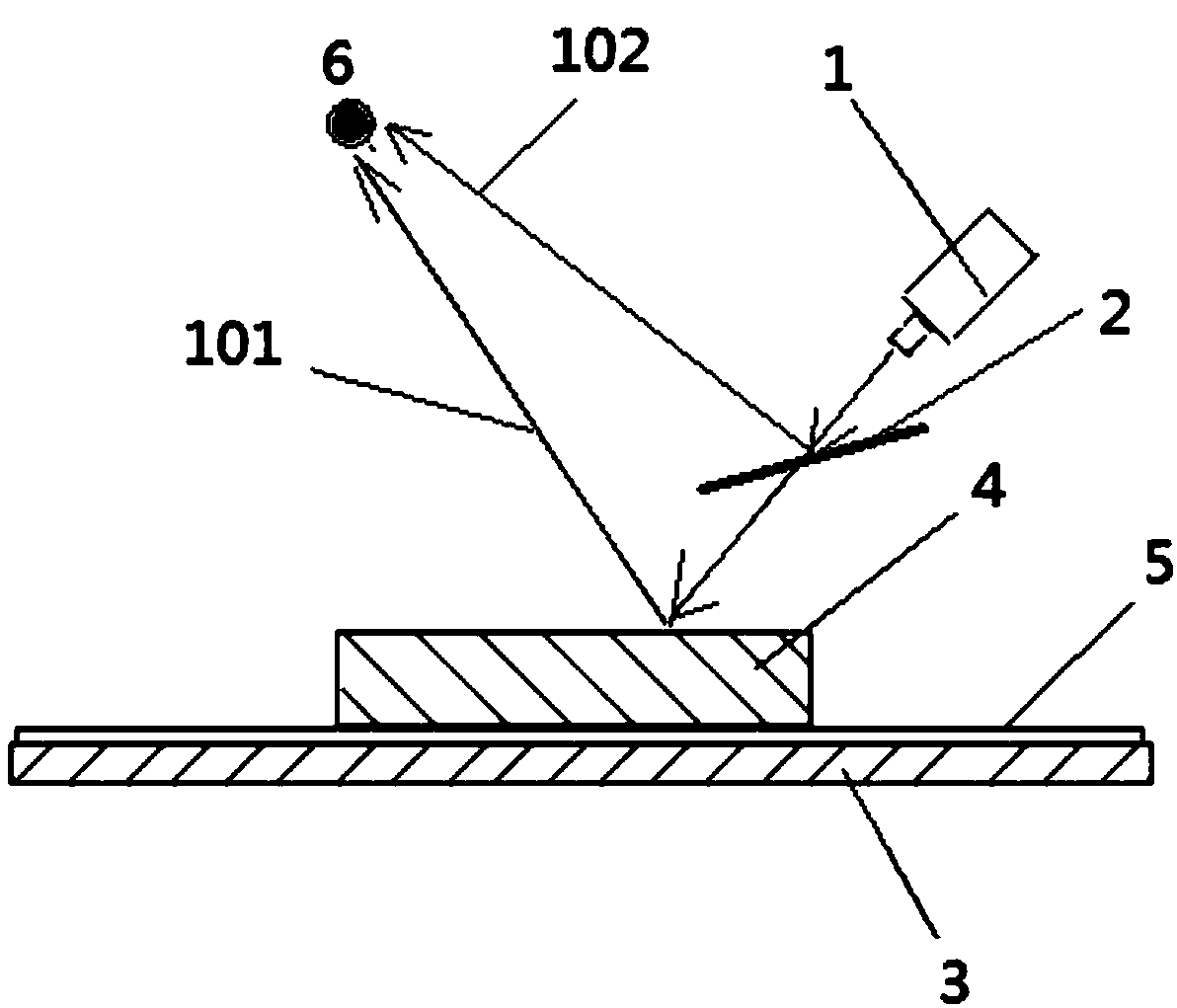

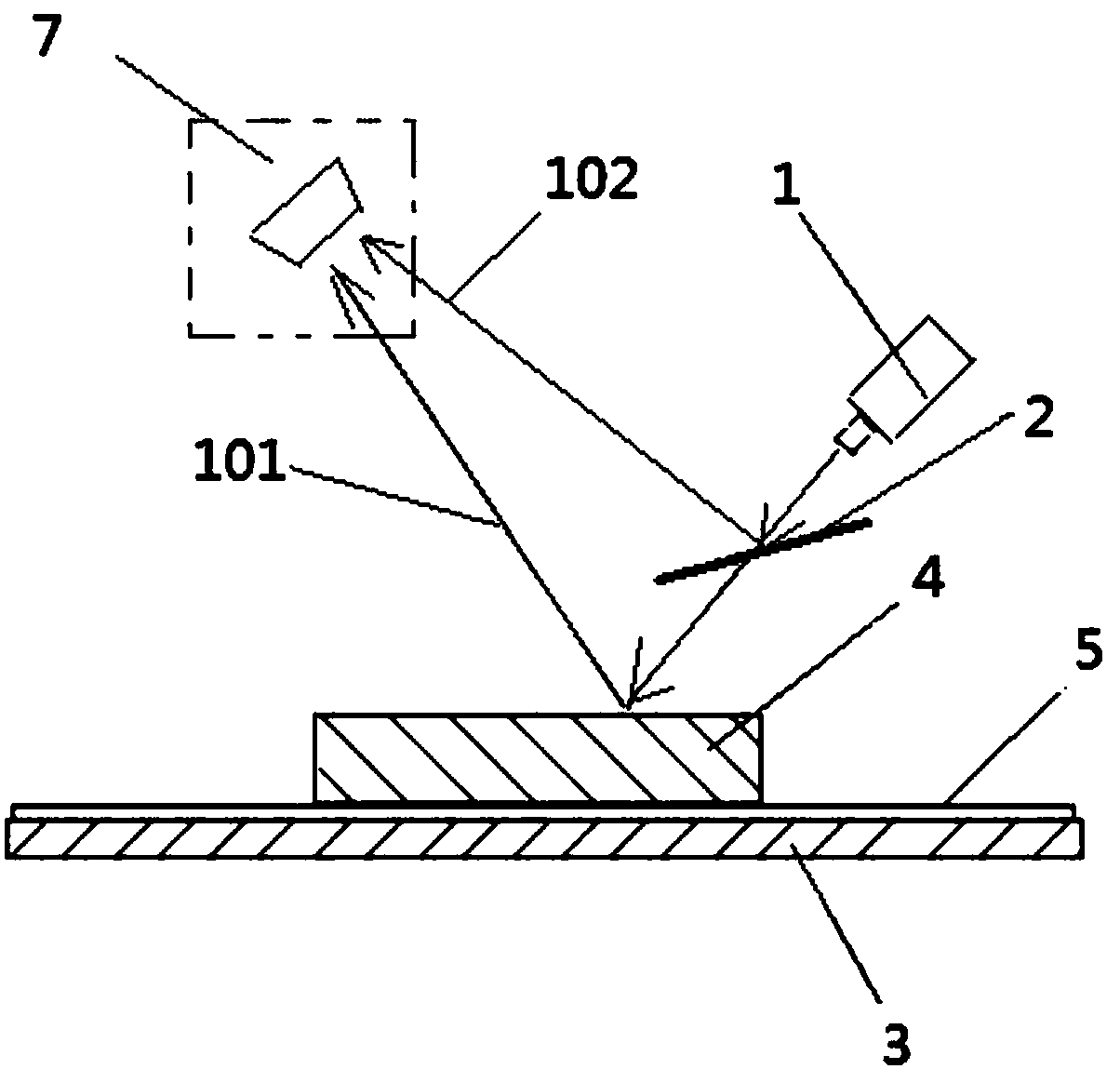

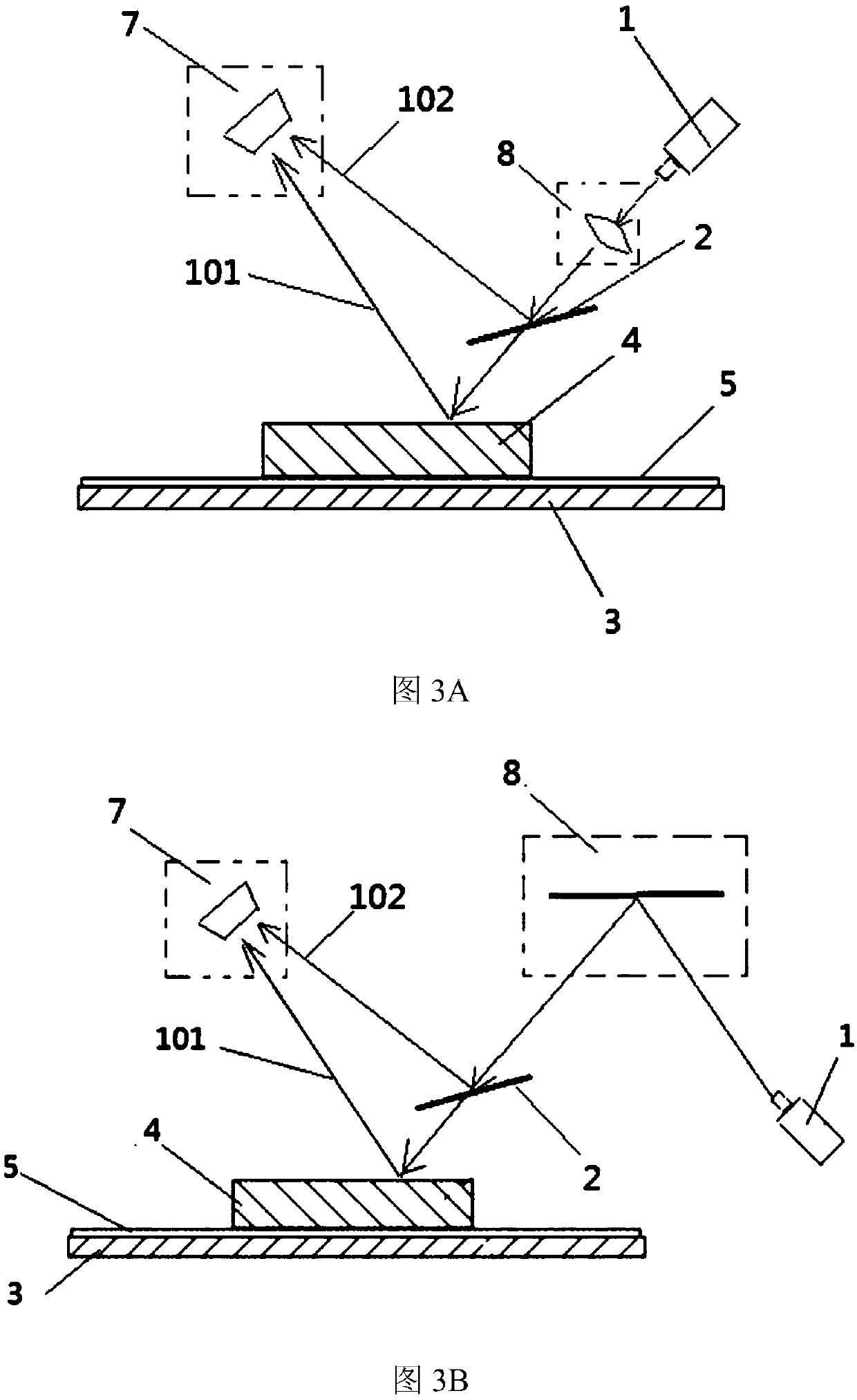

[0017] see figure 1 , the reflective laser lighting system of the present invention includes: a light source 1, a beam splitter 2, a substrate 3, a wavelength conversion layer 4 and a reflective film layer 5;

[0018] The substrate 3, the reflective film layer 5 and the wavelength conversion layer 4 are compounded sequentially;

[0019] The beam splitter 2 is arranged between the light source 1 and the wavelength conversion layer 4, the light beam emitted by the light source 1 is incident on the beam splitter 2, and the reflected beam 102 and the split light passing through the beam are obtained. After the mirror 2 shoots the wavelength conversion reflected beam 101 on the wavelength conversion layer 4, the reflected beam 102 and the wavelength conversion reflected beam 101 converge at the beam converging point 6 to obtain mixed light;

[0020] That is, the beam splitter 2 is arranged between the light source and the wavelength conversion layer, and the end point of the optic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com