Divided-plate liquid rubber composite node provided with damping through holes and forming method

A liquid rubber, split-type technology, applied in the field of rail transit, can solve the problems of low stiffness performance, large wheel-rail and line wear, and high maintenance costs, and achieve the effect of improving critical speed and curve performance and reducing wear and tear.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

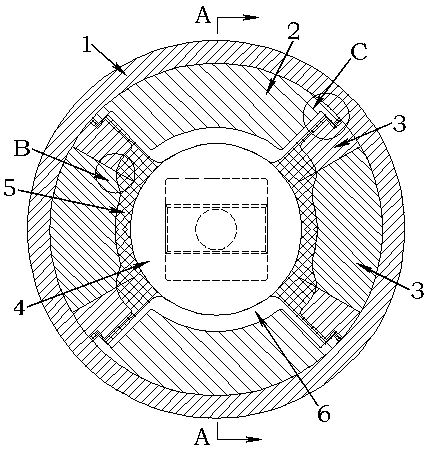

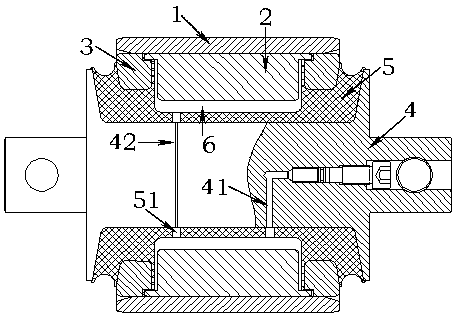

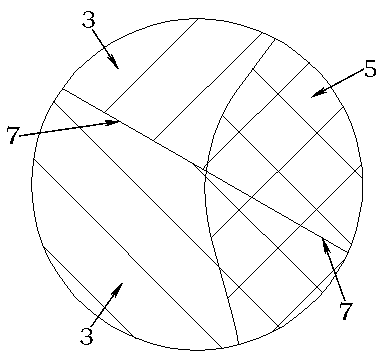

[0024] like figure 1 , figure 2 , Figure 4 and Figure 5 As shown, the liquid rubber composite node includes an outer casing 1 , a cover plate 2 , an intermediate spacer 3 , a rubber body 5 and a mandrel 4 . The rubber body 5 is vulcanized between the middle spacer 3 and the mandrel 4, so that the middle spacer 3, the rubber body 5 and the mandrel 4 are connected as a whole. The two ends on the outside of the cover plate 2 are provided with arc-shaped laps 21 protruding from the cover plate 2, and the outside of the middle spacer 3 is provided with a step opening 31, and the rubber body 5 is vulcanized at the step opening 31, and the arc-shaped laps at the two ends of the cover plate 2 The side 21 covers the rubber body 5 at the step opening 31 , and the cover plate 2 , the middle spacer 3 , the rubber body 5 and the mandrel 4 are assembled into the outer casing 1 together. A liquid cavity 6 is provided between the cover plate 2 and the rubber body 5 , and the liquid cav...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com