A kind of treatment method of high-concentration stripping liquid wastewater

A treatment method and technology of a wastewater treatment system, applied in the field of wastewater treatment, can solve the problems of ecological environment and human health hazards, high concentration of organic wastewater, and low treatment efficiency, and achieve the effects of easy acceptance, low operating costs, and increased treatment capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

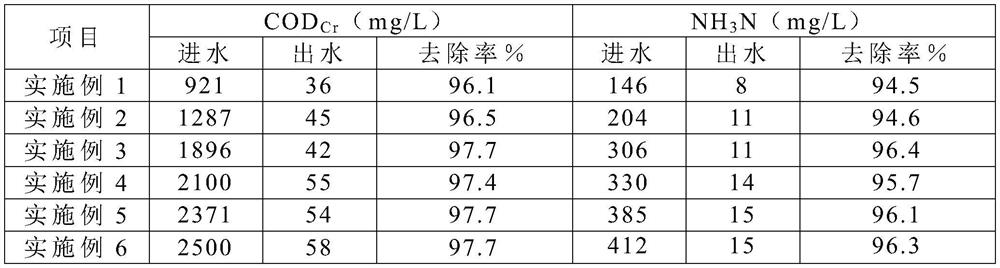

Embodiment 1-6

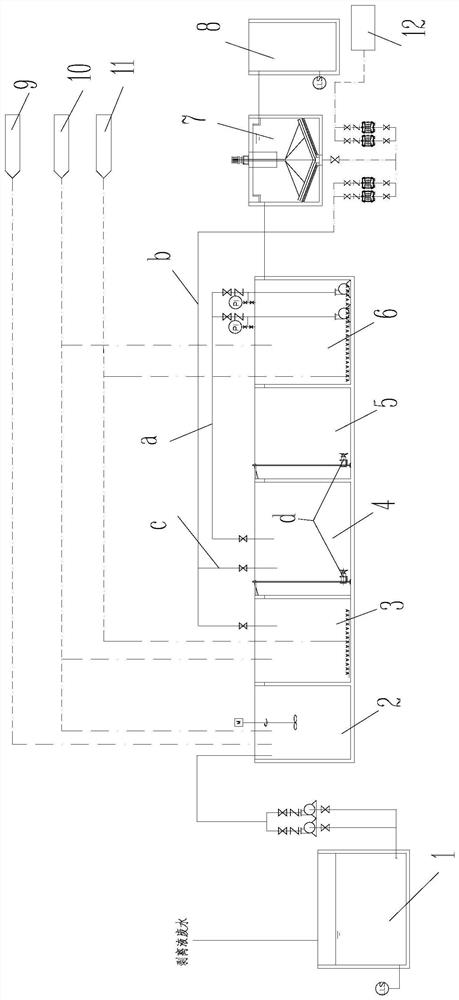

[0030] These embodiments provide a kind of treatment method of stripping liquid waste water, described stripping liquid waste water comprises dimethyl sulfoxide and ethanolamine, and described treatment method comprises the following steps:

[0031] (1) Adjust the pH value of the stripping liquid wastewater to 9 ± 0.2 by adding sulfuric acid aqueous solution;

[0032] (2) Pass the stripping liquid waste water after step (1) treatment into the moving bed biofilm reaction tank that contains Phylophagium and Thiobacillus for 24h, carry out aeration treatment simultaneously in the process, control the system during the treatment process The pH value is at 7.5 ± 0.2 (the pH value of the system can be maintained by adding aqueous sodium hydroxide solution), which can realize the conversion of dimethyl sulfoxide into sulfate;

[0033] (3) the stripping liquid waste water after step (2) is processed is passed in the anoxic pond and carries out denitrification treatment (some following...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com