OPC drum batch-processing method capable of improving dropoff problem

A batch processing method and workpiece technology, applied to the surface coating liquid device, pretreatment surface, coating, etc., can solve the problems that it is difficult to guarantee the quality of processed products, and the product quality of OPC drum products is uneven. Achieve easy to understand, uniform color, increase product quantity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

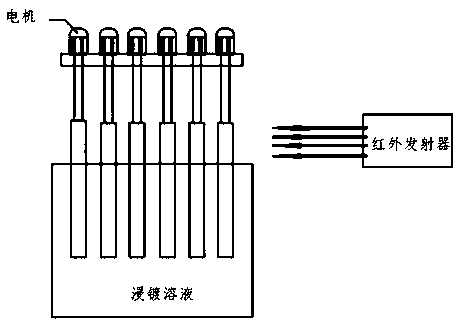

Image

Examples

Embodiment 1

[0044] The PLC of the two-axis processing robot is adjusted and the infrared heating process is added. The temperature of the upper end of the substrate aluminum tube reaches 52 degrees during the lifting process, and the thickness of the organic polymer conductive layer formed on the surface of the substrate aluminum tube is 24.5 um. The obtained OPC drum product has a dropoff of 2.8, an increase of about 1.0. The blackness of the test print is 1.45, the bottom ash is 0.02, and the binding force in a high-humidity environment is 90%. The color of the printed sample is uniform.

Embodiment 2

[0046] Adjust the PLC of the biaxial processing robot, add an infrared heating process, the temperature of the upper end of the substrate aluminum tube reaches 50 degrees during the lifting process, and the thickness of the organic polymer conductive layer formed on the surface of the substrate aluminum tube is 30um . The obtained OPC drum product has a dropoff of 3.5, an increase of about 2.0. The blackness of the test print is 1.38, the bottom ash is 0.02, and the bonding force in a high-humidity environment is 98%. The color of the printed sample is uniform.

[0047] The present invention also provides references for other related problems in the same field, and can be expanded and extended based on this, and applied to other related technical solutions of OPC drum immersion plating processing, and has very broad application prospects.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com