Two-stage rectangular stacked microchannel cooler

A micro-channel and refrigerator technology, which is applied in refrigerators, refrigeration and liquefaction, lighting and heating equipment, etc., can solve the problems of small air intake, low pressure bearing capacity of refrigerators, and low cooling capacity, and achieves improved compactness. , Enhance the effect of disturbance and heat transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

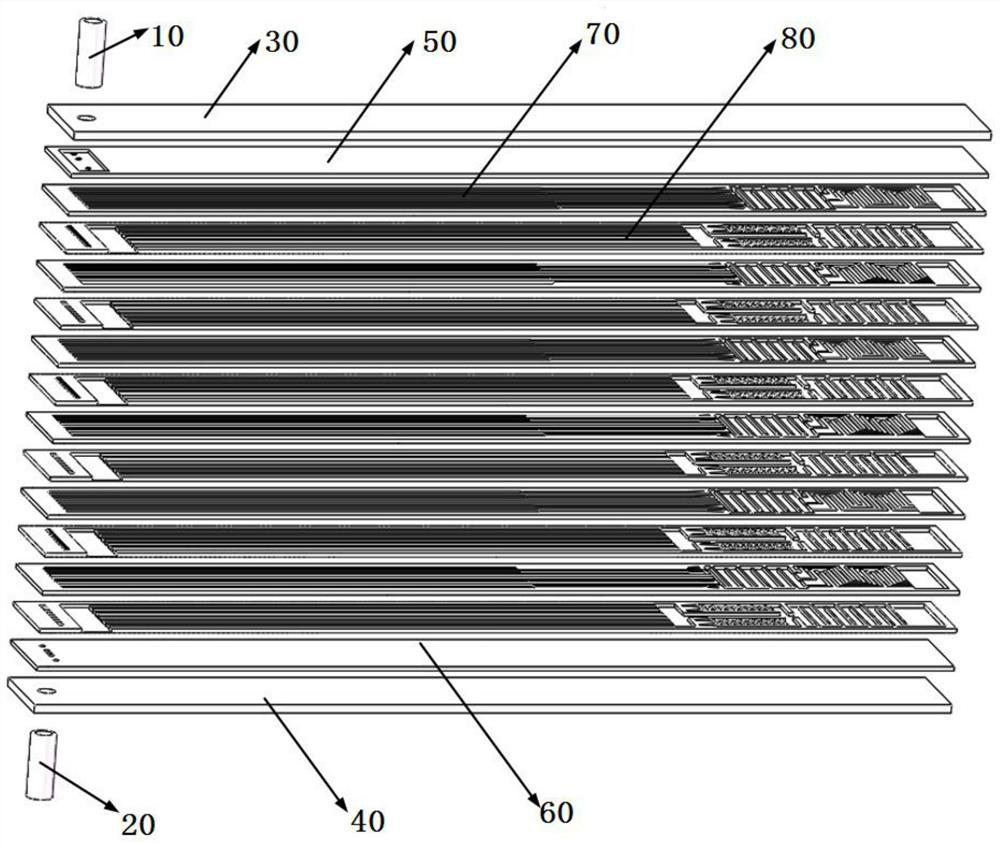

[0028] Such as figure 1 , 2 As shown, the two-stage rectangular laminated micro-channel refrigerator includes an upper cover plate 30, an upper inner cover plate 50, a plurality of high-pressure channel plates 70 and a plurality of low-pressure channel plates 80 stacked up and down, and a lower inner cover. plate 60 , lower cover plate 40 , primary air intake pipe 10 , and secondary air intake pipe 20 .

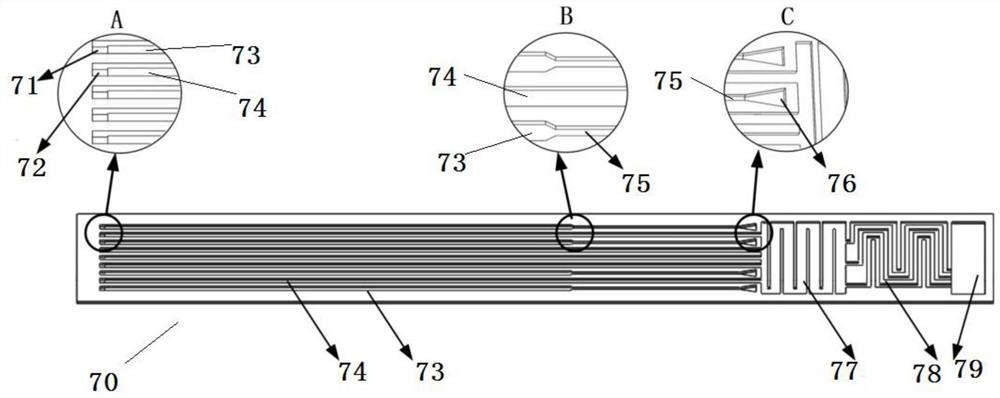

[0029] The high-pressure channel plate 70 is rectangular and includes heat exchange sections and evaporation chambers arranged in sequence.

[0030] Such as image 3 As shown, the heat exchange section of the high-pressure channel plate 70 includes a first channel section, a pre-cooling section 77 , and a secondary channel section arranged in sequence.

[0031] The first channel section includes a plurality of flow channels 73 , 74 and 75 .

[0032] The flow channel 73, the flow channel 74, and the flow channel 75 respectively include a plurality of concave linear grooves...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com