Nuclear power plant vapor generator sewerage system

A technology of steam generator and blowdown system, which is applied in the direction of boiler cleaning equipment, etc., and can solve problems such as shutdown maintenance, abnormal sound in the pipe, shutdown inspection, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

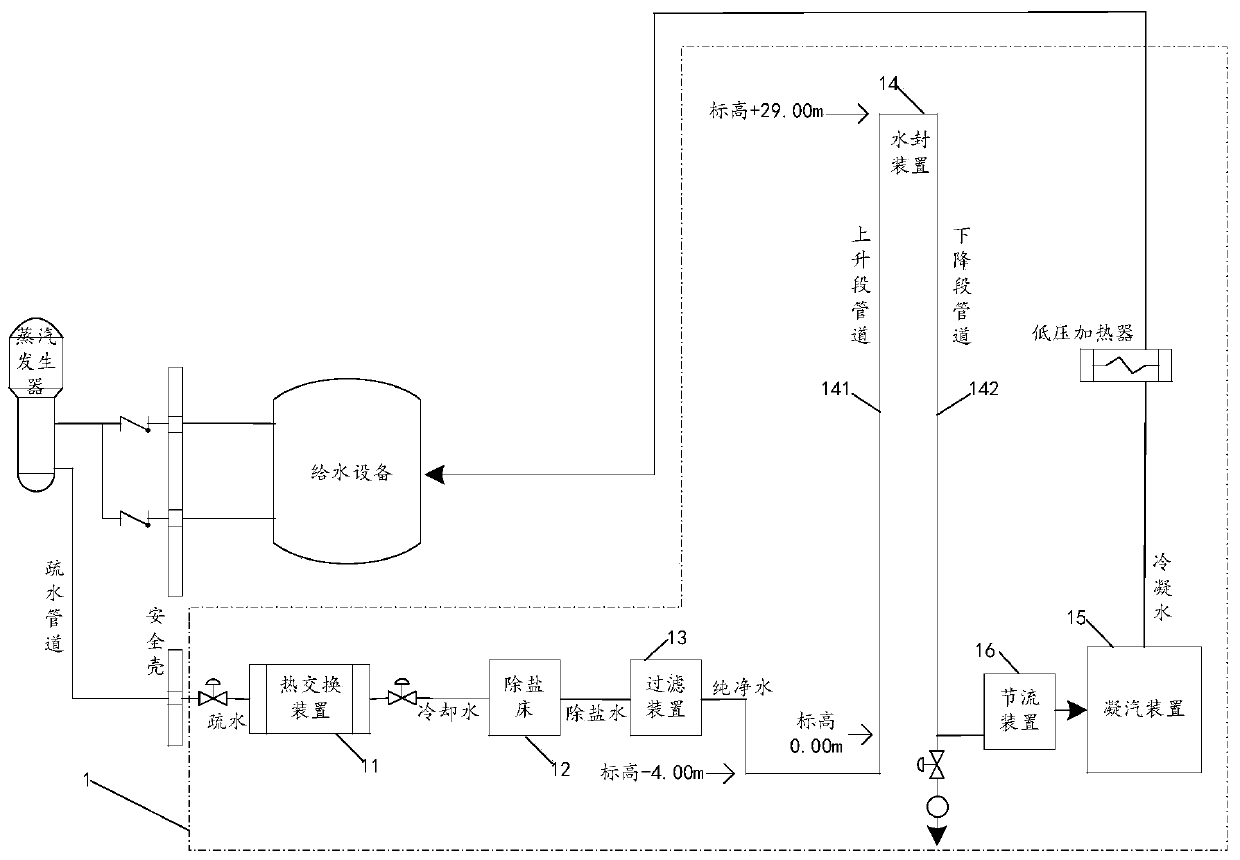

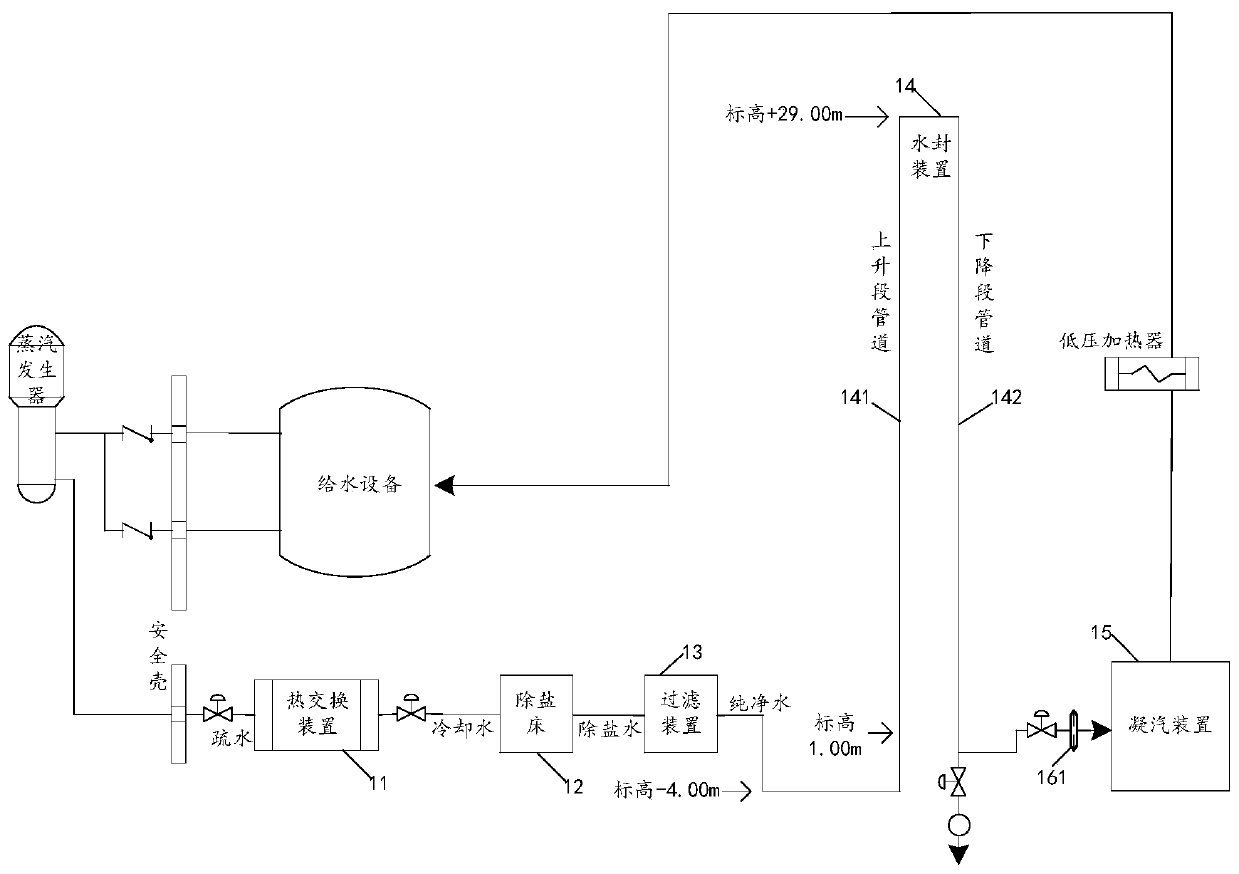

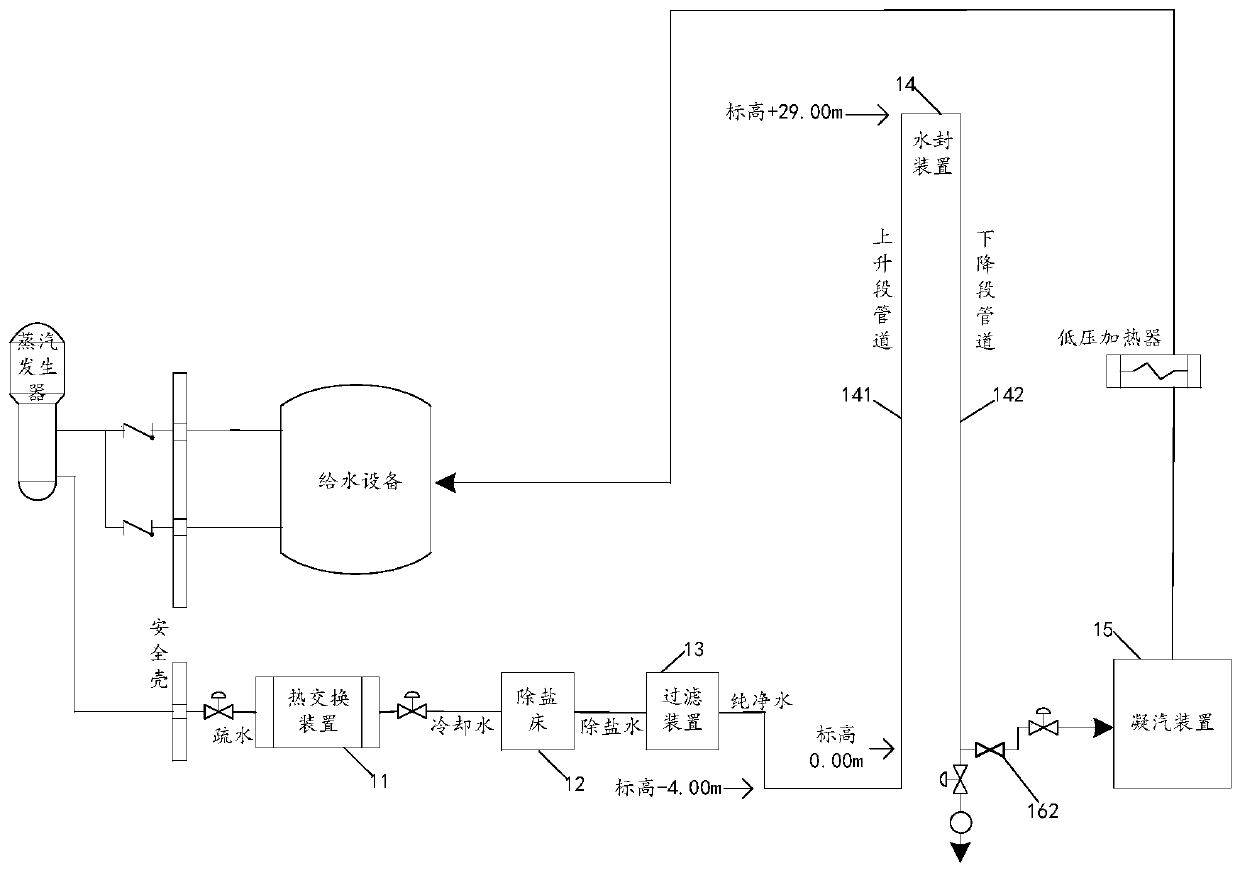

[0035] Please refer to figure 1 , the application discloses a nuclear power plant steam generator sewage system, which can effectively prevent the occurrence of water hammer in the pipeline. The nuclear power plant steam generator sewage system 1 mainly includes a heat exchange device 11, a desalination bed 12, a filter device 13, Sealing device 14, condensing device 15 and throttling device 16 are described respectively below.

[0036] The heat exchange device 11 is connected to the drain pipeline of the steam generator. The heat exchange device 11 is used to cool the drain generated by the steam generator to output cooling water. The cooling function of the heat exchange device 11 reduces the temperature of the drain to a preset value. below the temperature.

[0037] The desalination bed 12 is connected with the heat exchange device 11 for receiving the cooling water output by the heat exchange device 11 and removing the dissolved salt in the cooling water to output the des...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com