Heat treatment method of GH4780 alloy forging

A heat treatment method, solid solution heat treatment technology, applied in the direction of engine components, blade support components, mechanical equipment, etc., can solve the problems of lack of heat treatment process for GH4780 alloy forgings, so as to promote dynamic recrystallization, eliminate voids, and refine grains Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0067] The heat treatment method of GH4780 alloy forgings includes the following steps:

[0068] 1. Carry out solution heat treatment on GH4780 alloy forgings, the temperature of the solution heat treatment is 1080℃, the time of solution heat treatment is 1h, and then the first cooling is carried out, the first cooling methods are air cooling, oil cooling and water cooling;

[0069] 2. The product obtained in step 1 is subjected to aging heat treatment, the temperature of the aging heat treatment is 800°C for 8 hours, and then air cooling is performed.

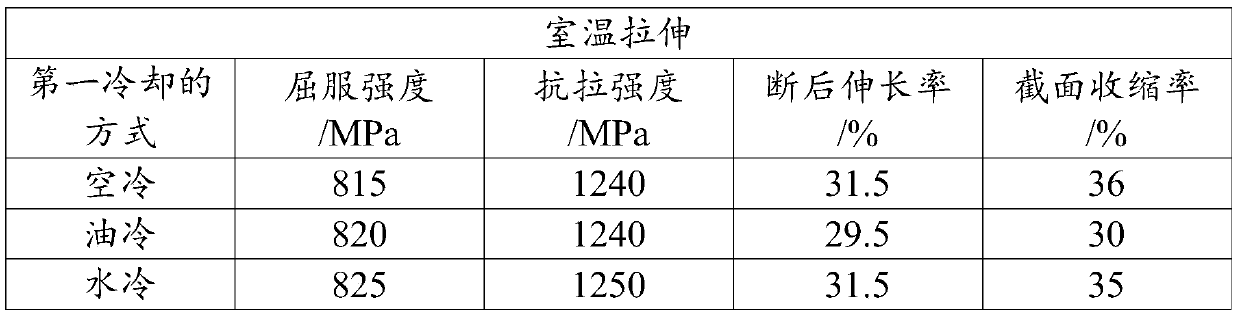

[0070] The mechanical properties of the GH4780 alloy device obtained after the heat treatment of the GH4780 alloy forging by the heat treatment method of this embodiment are stretched at room temperature and stretched at 760°C are shown in Table 1 and Table 2, respectively:

[0071] Table 1

[0072]

[0073] Table 2

[0074]

Embodiment 2

[0076] The heat treatment method of GH4780 alloy forgings includes the following steps:

[0077] 1. Carry out solution heat treatment on GH4780 alloy forgings, the temperature of the solution heat treatment is 1070℃, the time of solution heat treatment is 1h, and then air cooling;

[0078] 2. The product obtained in step 1 is subjected to aging heat treatment, the temperature of the aging heat treatment is 800°C for 8 hours, and then air cooling is performed.

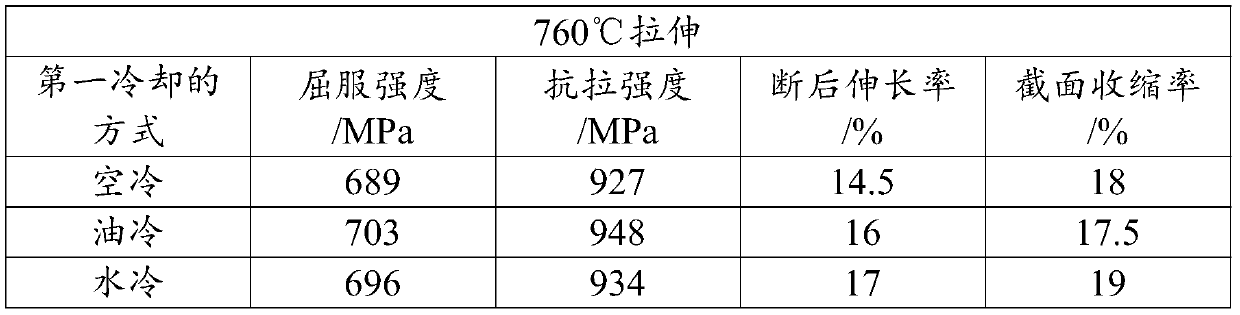

[0079] The mechanical properties of the GH4780 alloy device obtained after the heat treatment of the GH4780 alloy forging using the heat treatment method of this embodiment are stretched at room temperature and at 760°C, respectively, as shown in Table 3 below:

[0080] table 3

[0081]

Embodiment 3

[0083] The heat treatment method of GH4780 alloy forgings includes the following steps:

[0084] 1. Carry out solution heat treatment on GH4780 alloy forgings, the temperature of the solution heat treatment is 1163℃, the time of solution heat treatment is 1h, and then air cooling;

[0085] 2. The product obtained in step 1 is subjected to aging heat treatment, the temperature of the aging heat treatment is 800 ℃, the time is 8 hours, and then air cooling is performed.

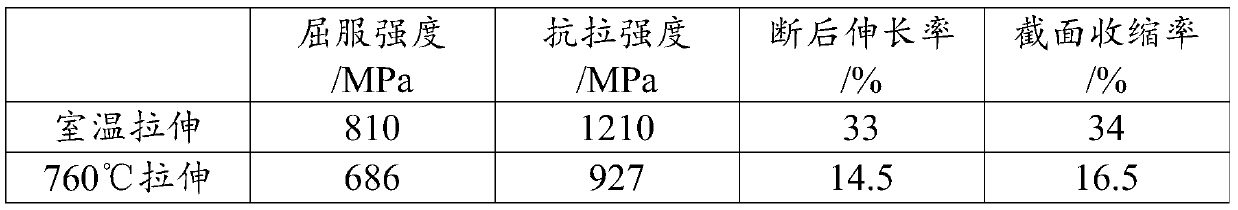

[0086] The mechanical properties of the GH4780 alloy device obtained after the heat treatment of the GH4780 alloy forging using the heat treatment method of this embodiment are stretched at room temperature and at 760°C, respectively, as shown in Table 4 below:

[0087] Table 4

[0088]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com