Multi-degree-of-freedom assembling system suitable for large size equipment assembly in cabin of spacecraft

An assembly system and a technology with a degree of freedom, which is applied to space navigation equipment, space navigation equipment, space navigation ground equipment, etc., can solve problems such as large subjective errors, excessive weight, and low positioning accuracy, so as to improve agility and Safety, reduction of human labor, high safety effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

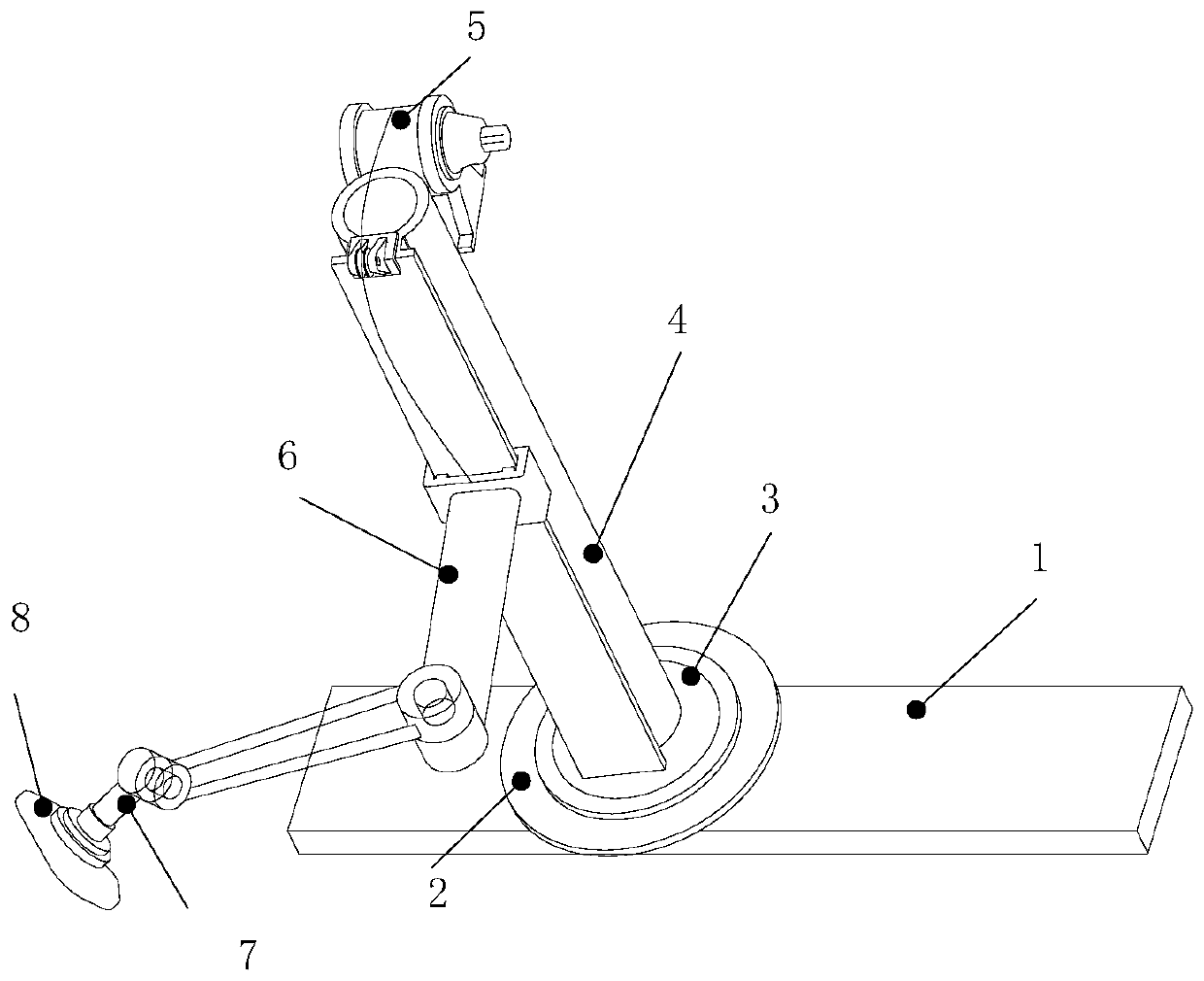

[0023] The multi-degree-of-freedom assembly system applicable to the assembly of equipment in a large cabin of a spacecraft is described below with reference to the accompanying drawings, but this description is only exemplary and is not intended to limit the protection scope of the present invention.

[0024] see figure 1 , figure 1 A two-dimensional schematic diagram of the assembly of the large cabin equipment of the spacecraft is shown. Among them, the multi-degree-of-freedom assembly system suitable for the assembly of large-scale spacecraft equipment in the present invention includes a horizontal track 1, a base 2, a slewing mechanism 3, a vertical track 4, a lifting mechanism 5, a boom drive 6, a small arm drive 7, End effector 8. Inside the cabin of the space station, there are instrument board structures in each area, forming a grid area one by one. In the process of final assembly, the section of the instrument board is transferred, the transfer board is laid, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com