Preparation method for changing titanium alloy into variable-wall thick hollow active cooling cabin

A technology of active cooling and variable wall thickness, which is applied in the field of cabin preparation to achieve the effects of high strength and rigidity, high forming accuracy and light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] In order to make the purpose, content and advantages of the present invention clearer, the specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

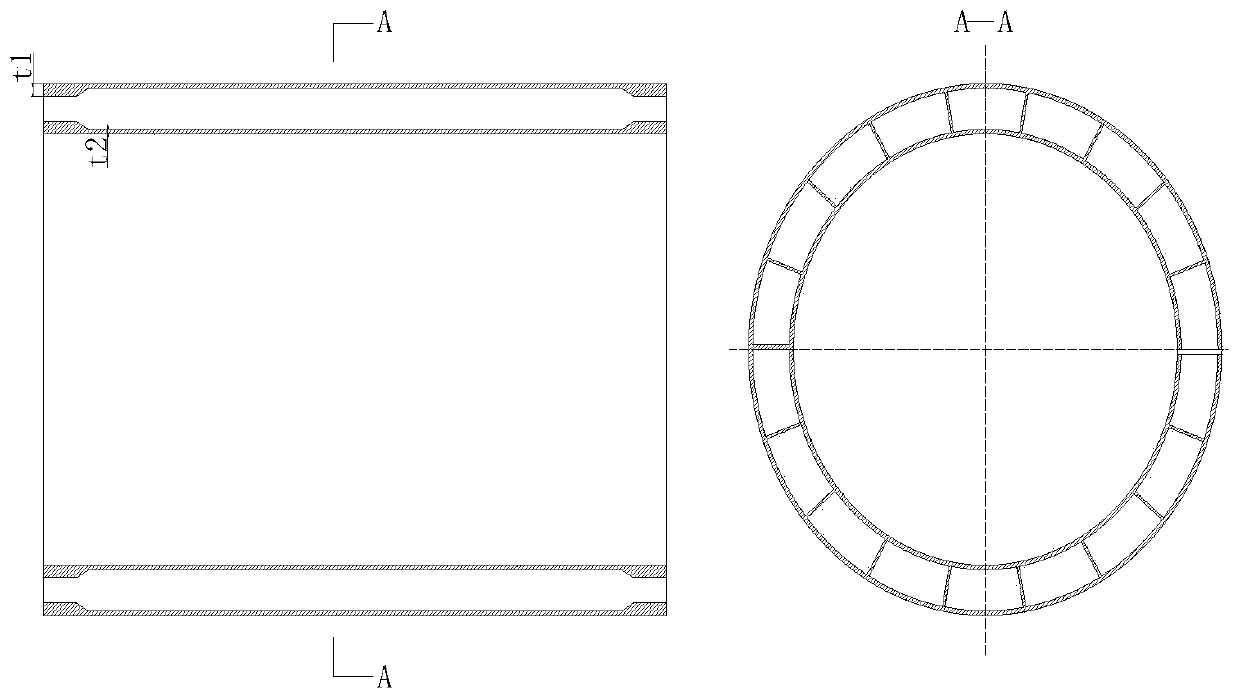

[0054] This embodiment proposes a method for preparing a titanium alloy variable-wall-thickness hollow active-cooling cabin. The variable-wall-thickness hollow active-cooling cabin is a 360° closed rotary body with a local reinforcement structure. The interior is a heading hollow structure. The wall thickness t1 is greater than the intermediate wall thickness t2, such as figure 1 shown.

[0055] The preparation method of the present embodiment specifically comprises the following steps:

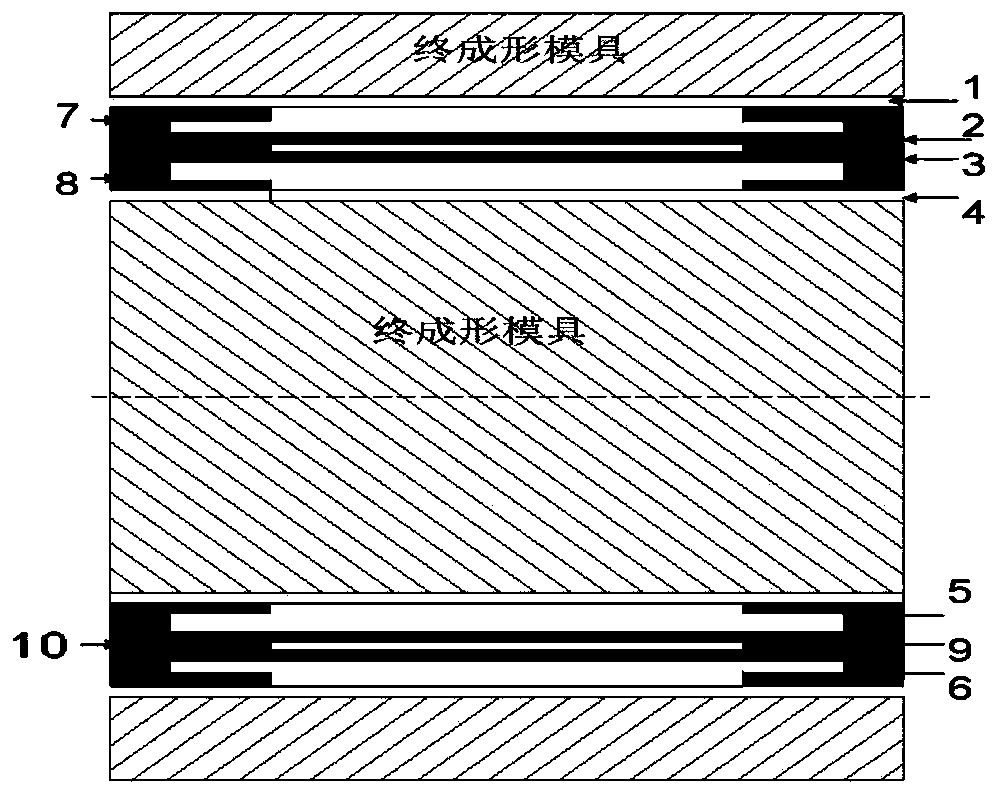

[0056] The first step, tube blank preparation: divide the hollow active cooling cabin with variable wall thickness into 10 titanium alloy tube blanks for preparation. Such as figure 2As shown, the 10 tube blanks are the outer tube ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com