Fermentation method for special sour soup

A fermentation method and technology for sour soup, applied in the field of fermentation of characteristic sour soup, can solve the problems of high nitrite content, high transportation cost, and olfactory stimulation in sour soup, and achieve low nitrite content, high nutritional value, and taste. mellow effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

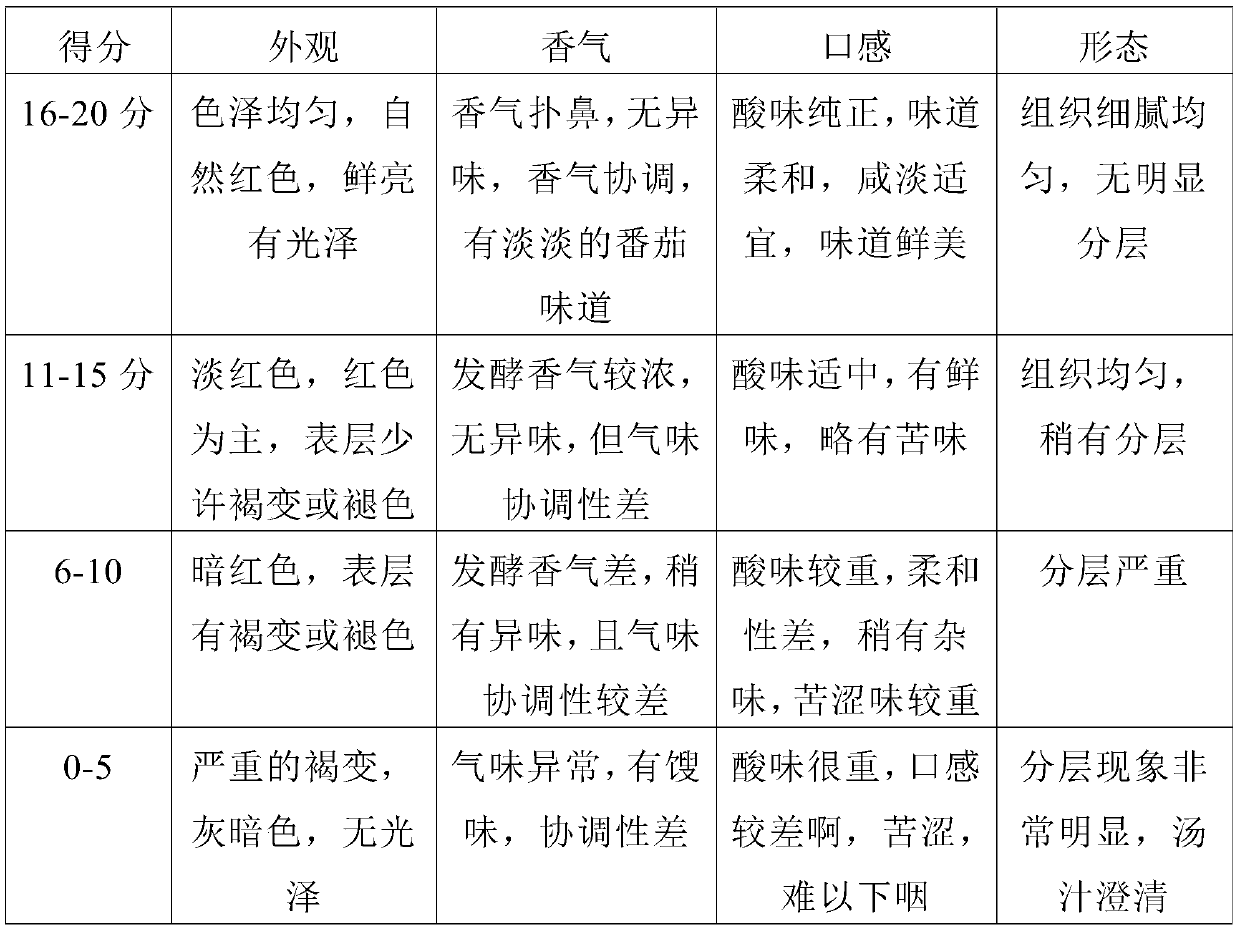

Examples

Embodiment 1

[0060] A method for fermenting characteristic sour soup, comprising the following steps:

[0061] (1) Preparation of white sour: crush rice, pass through 80 mesh sieve to obtain rice flour, mix rice flour, wheat flour and corn flour according to mass ratio of 10:2:2 to obtain white sour fermentation raw material, mix white sour fermentation raw material with After mixing water at a mass ratio of 1:10, heat up to 90°C at 5°C / min while stirring at 60 rpm to obtain a mixture, add liquor with 2% of the mass of the mixture into the mixture, seal and ferment at 28°C 8 days, get white acid;

[0062] (2) Preparation of red acid: wash the tomato with water, dry it, then wash it with white wine, dry it, cut it into tomato pieces with a length and width of 0.5-1.2cm to obtain tomato pieces, and mix the tomato pieces and salt according to the mass ratio Mix evenly at a ratio of 100:5, seal and ferment at 28°C for 8 days to obtain red acid;

[0063] (3) Making bad peppers: wash red peppe...

Embodiment 2

[0068] A method for fermenting characteristic sour soup, comprising the following steps:

[0069] (1) Preparation of white sour: crush rice, pass through 80 mesh sieve to obtain rice flour, mix rice flour, wheat flour and corn flour according to mass ratio of 10:2:2 to obtain white sour fermentation raw material, mix white sour fermentation raw material with After mixing water at a mass ratio of 1:10, heat up to 90°C at 5°C / min while stirring at 60 rpm to obtain the mixture, and then inoculate the mixture with the inoculation amount of 2mL / kg mixture, and add Liquor with 2% of the mass of the mixture, sealed and fermented at 28°C for 8 days to obtain white sour;

[0070] (2) Preparation of red acid: wash the tomato with water, dry it, then wash it with white wine, dry it, and cut it into tomato pieces with a length and width of 0.5-1.2cm to obtain tomato pieces. Mix evenly at a ratio of 100:5, then inoculate the mixed bacteria, the inoculum amount is 2mL / kg tomato block, seal...

Embodiment 3

[0078] A method for fermenting characteristic sour soup, comprising the following steps:

[0079] (1) Preparation of white sour: crush rice, pass through 80 mesh sieve to obtain rice flour, mix rice flour, wheat flour and corn flour according to the mass ratio of 10:2:2 to obtain white sour fermentation raw material, mix white sour fermentation raw material with After mixing water at a mass ratio of 1:10, heat up to 90°C at 5°C / min while stirring at 60 rpm to obtain the mixture, and then inoculate the mixture with the inoculation amount of 2mL / kg mixture, add Liquor with 2% of the mass of the mixture, sealed and fermented at 28°C for 8 days to obtain white sour;

[0080] (2) Preparation of red acid: wash the tomato with water, dry it, then wash it with white wine, dry it, cut it into tomato pieces with a length and width of 0.5-1.2cm to obtain tomato pieces, mix the tomato pieces with salt and flavoring agent Mix evenly according to the mass ratio of 100:5:5, then inoculate t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com