Method and instrument for profiling magnetic flux

A magnetic flux density, stator technology, applied in the direction of electrical components, electromechanical devices, windings, etc., can solve the problems of lack of manufacturing process and connection process, weak electrical characteristics, etc., to reduce size and weight, reduce heat generation, and easy to manufacture Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

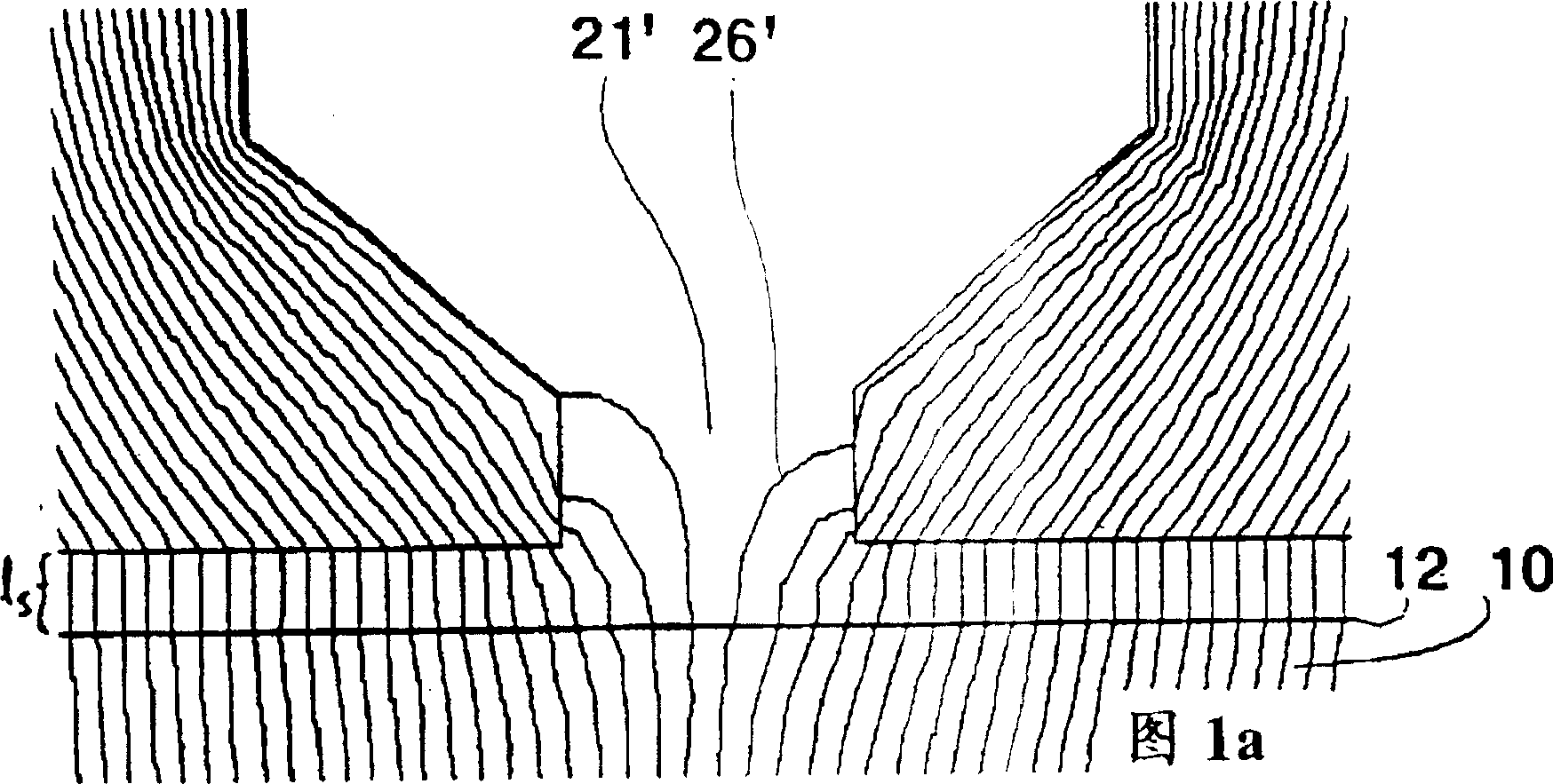

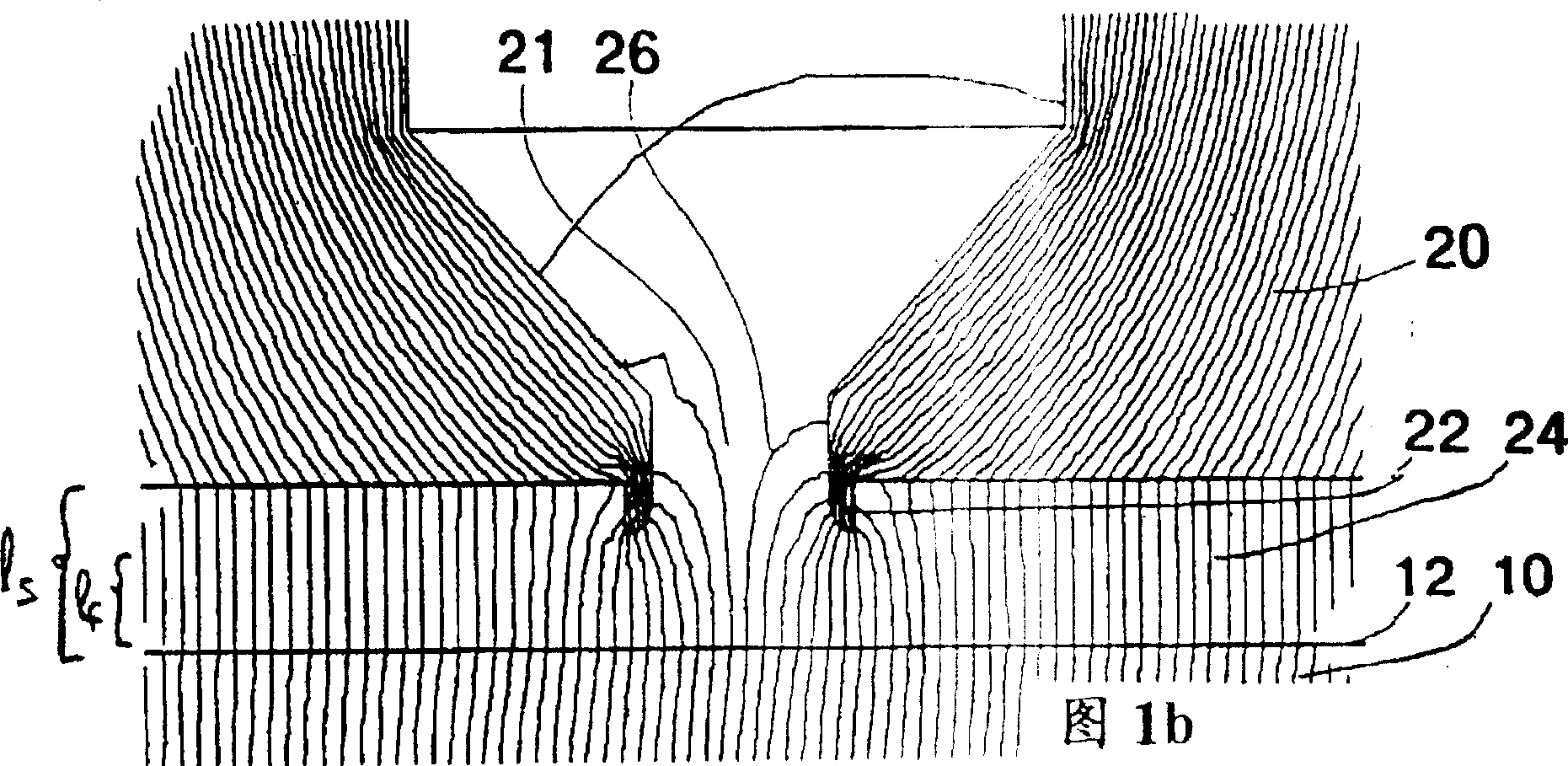

[0026] Figure 1a shows a stator slot 21' used in the prior art, in which the shape of the stator slot 21' is partially enlarged. The magnetic flux density distributed in the air gap Is is indicated by the line 26'. Appendix 1b shows a tooth 22 which extends from the stator laminations 20 on both sides of the stator slot 21 into the rotor bore 24 . The advantageous effect of the teeth on the distribution of the magnetic flux density can be seen from the magnetic flux lines 26 .

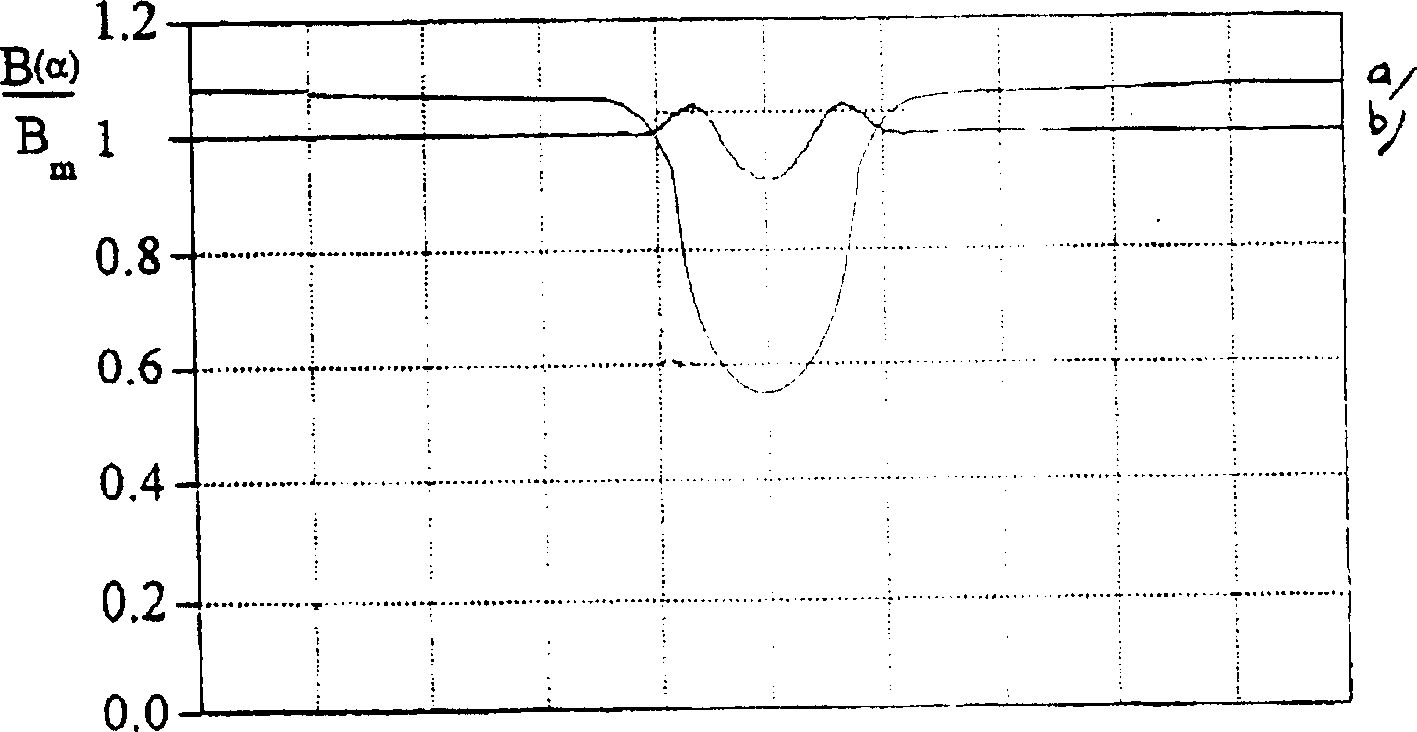

[0027] attached by Figure 1c As can be seen from the graph shown, the toothed stator teeth 22 provide a much more uniform flux distribution (b) than the conventional approach (a). The stator device 20 has some slots, the shape of which is shown in Figure 1b. Since the influence of the permeance harmonics is reduced, the heating effect of the permeance harmonics on the rotor 10 will not be too great. However, this method still suffers from some of the disadvantages mentioned above.

[0028] Accompan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com