Method and instrument for profiling magnetic flux

A magnetic flux density, stator technology, applied in the direction of electrical components, electromechanical devices, windings, etc., can solve the problems of lack of manufacturing process and connection process, weak electrical characteristics, etc., to reduce size and weight, reduce heating problems, and improve efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

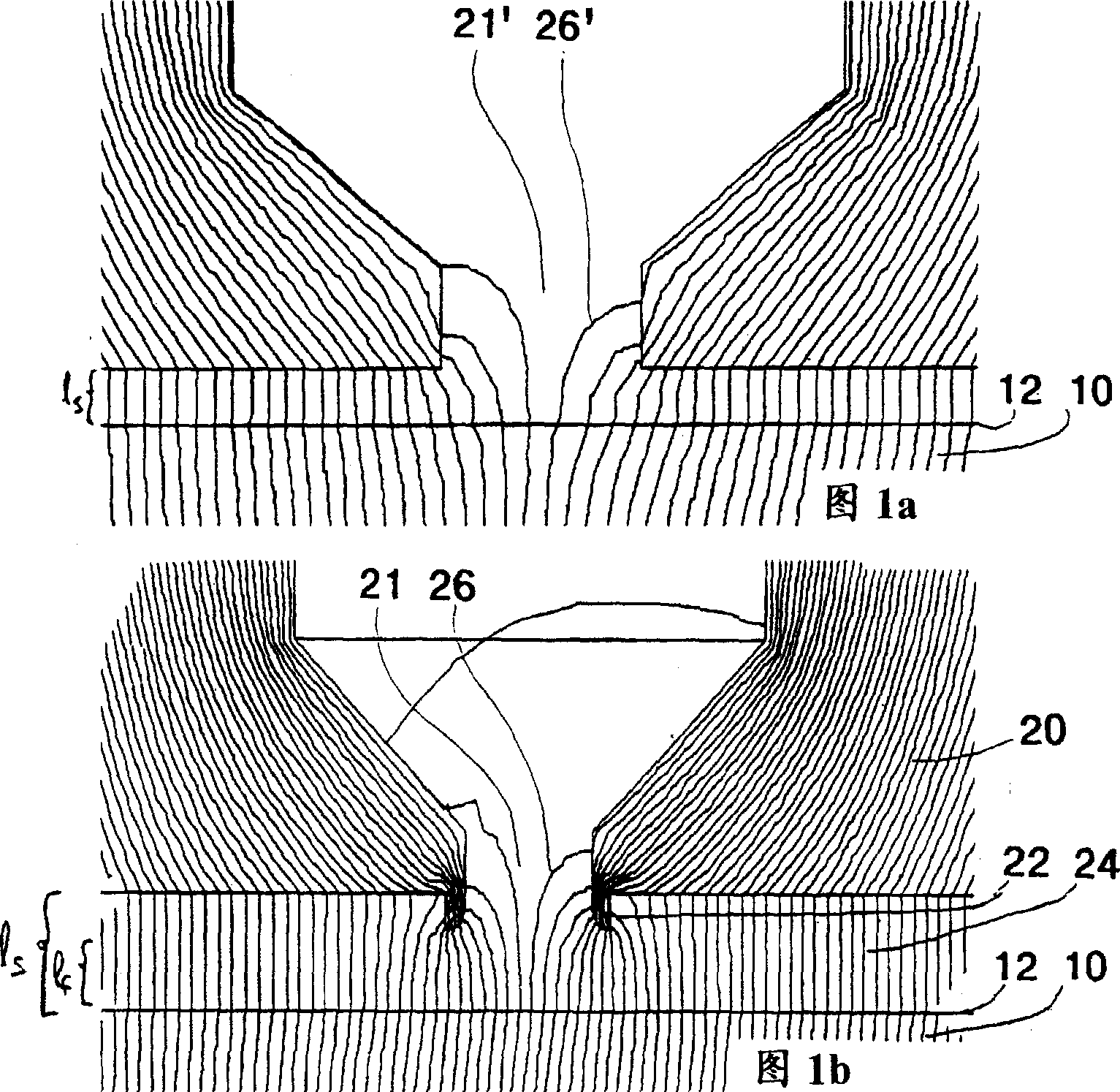

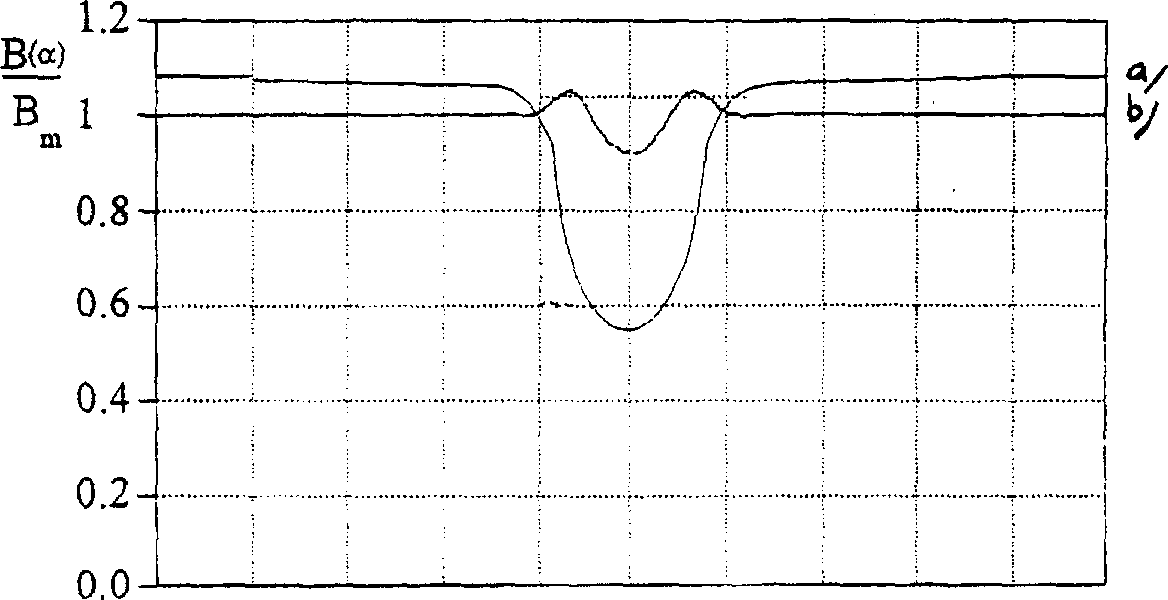

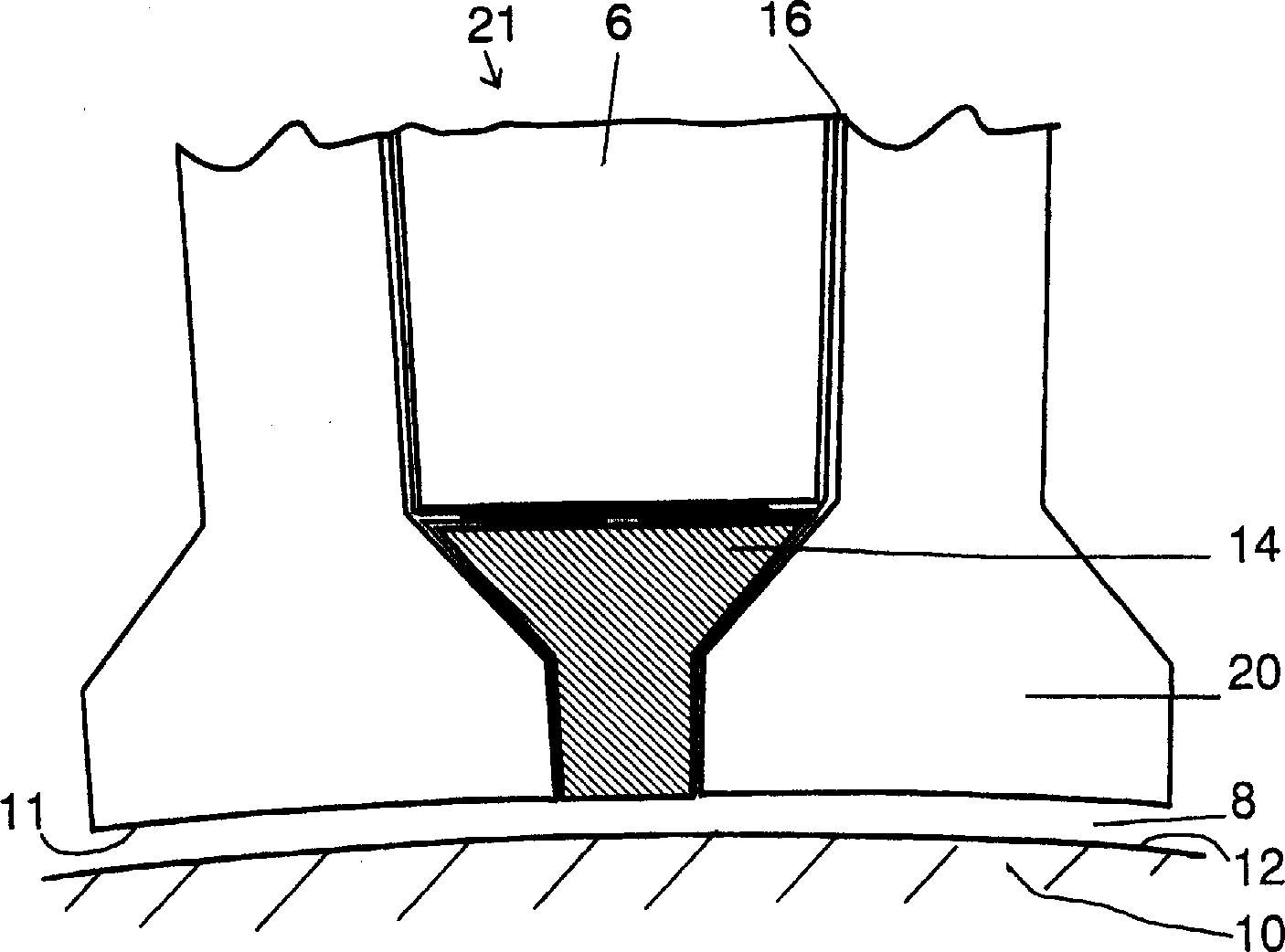

[0015] According to a preferred embodiment of the invention, the electric machine comprises a rotor means and a stator means surrounding the rotor means, and the stator means has a plurality of radially extending slots. At least some of the slots contain slot-lock elements characterized in that they extend within the slots around the rotor bore of the stator assembly and that the relative permeability of the slot-lock elements (µ r ) is better, μ r Greater than 5, in addition, its saturation magnetic flux density is at least 0.2T.

[0016] Preferably, the resistivity of the material is as high as possible, and preferably its resistivity substantially matches that of an insulator. In addition, the material should have sufficient heat-resistant strength.

[0017] According to the method of the invention, a stator lock is installed in the stator slot of the motor. This stator lock extends in the slot to around the rotor hole of the stator device, and the material it chooses ha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Saturation flux density | aaaaa | aaaaa |

| Saturation flux density | aaaaa | aaaaa |

| Saturation flux density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com