Preparation method for vulcanized sealant for fuel cells

A fuel cell and sealant technology, which is applied to fuel cell parts, sealing/supporting devices, and final product manufacturing, can solve problems such as poor production capacity, high energy consumption, and unfavorable production lines, and improve production efficiency. , Reduce energy loss and improve product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

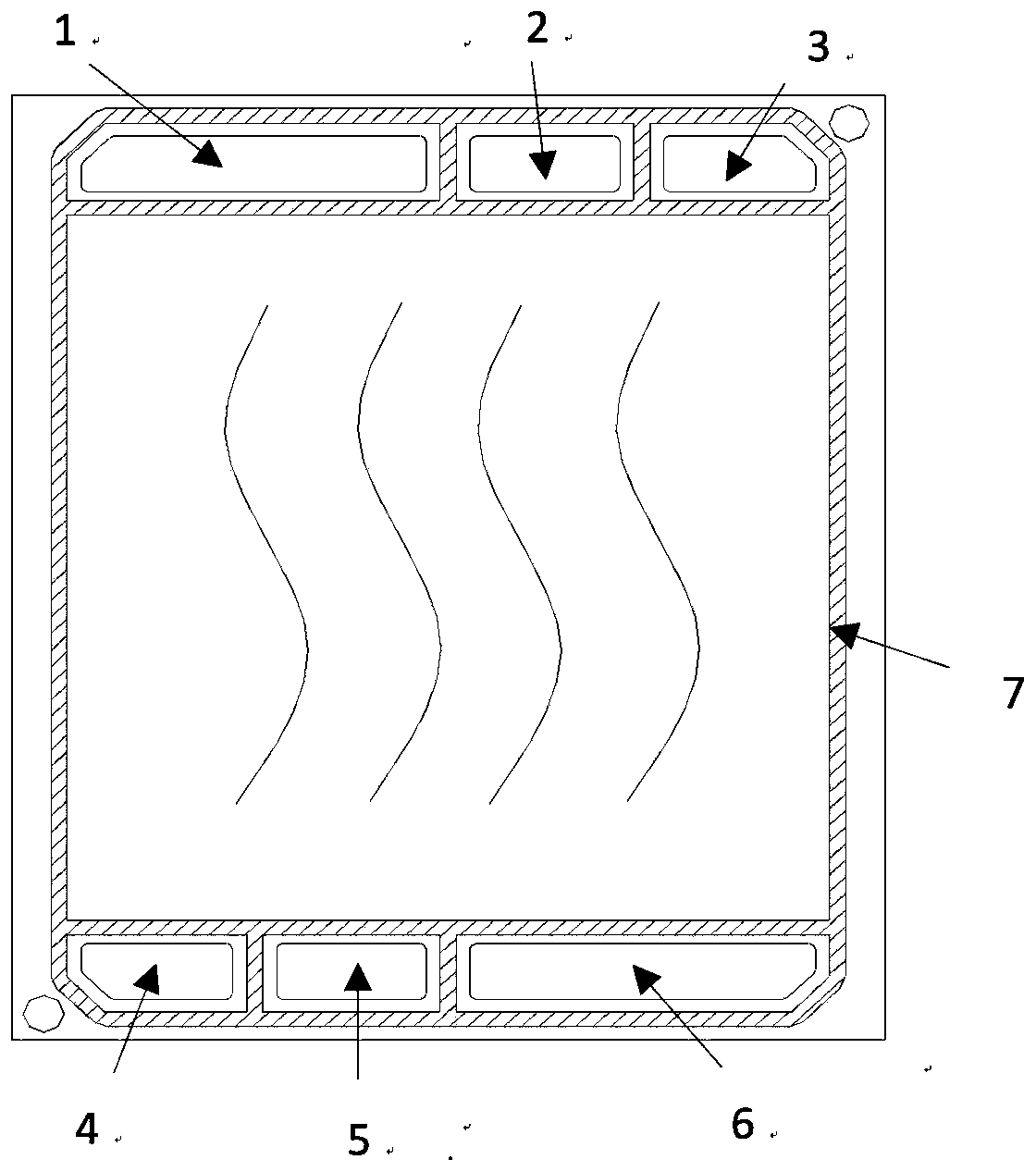

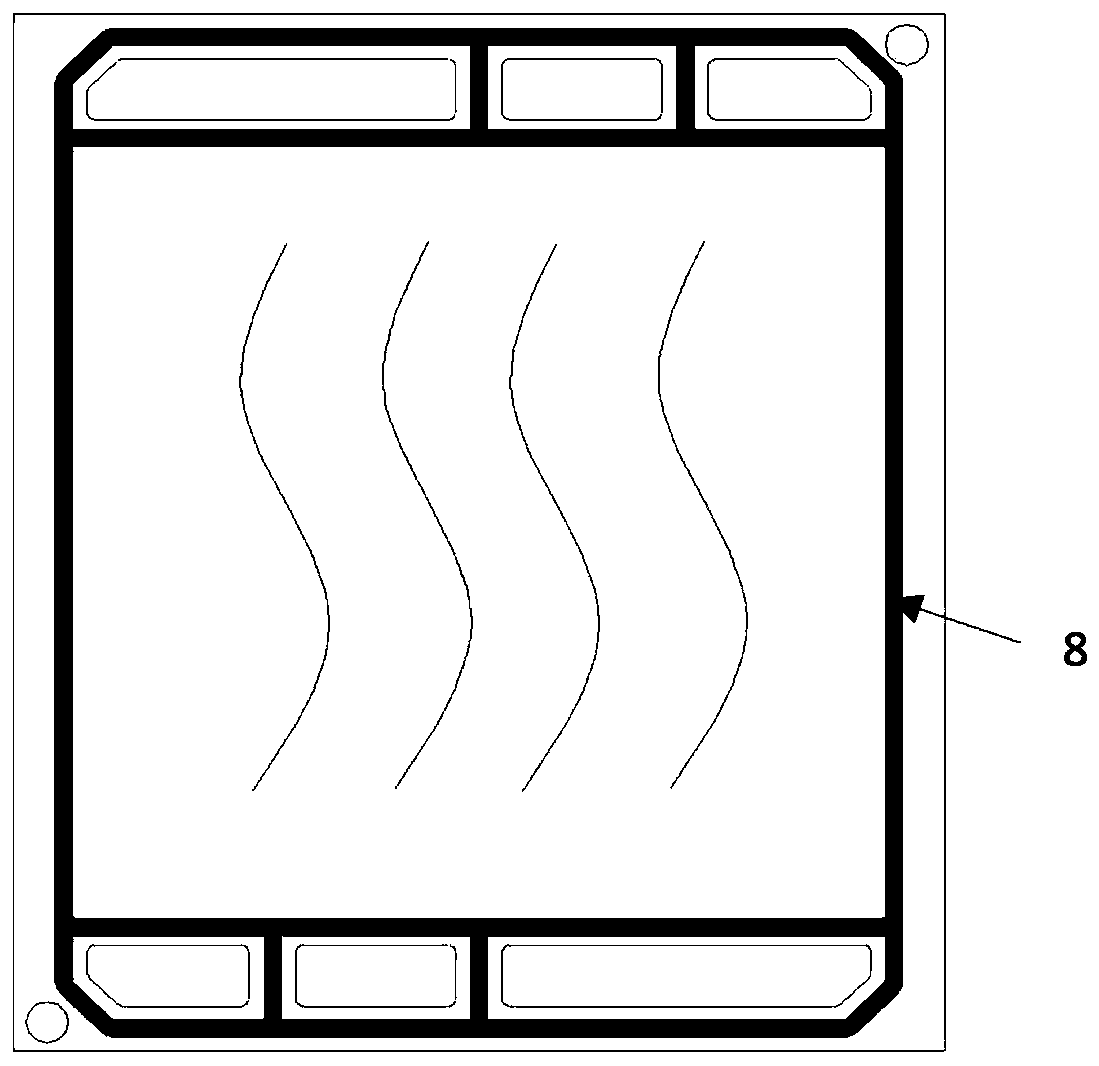

[0036] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. However, the present invention is not limited to the embodiments described below. In addition, the technical features involved in the various embodiments of the present invention described below can be combined with each other as long as there is no conflict with each other, and the technical idea of the present invention can be combined with other known technologies or other technologies that are the same as those known technologies implement.

[0037] Unless otherwise specified, the qualifiers similar to "first" and "second" appearing in this article do not refer to the limitation of time sequence, quantity, or importance, but are only for the purpose of combining one technology in this technical solution A characteristic is distinguished from another technical characteristic. Likewise, modifiers like "about" and "approximately" that appea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com