Constant calibration method for differential absorption laser radar system

A technology of laser radar and system constants, applied in radio wave measurement systems, instruments, measuring devices, etc., can solve problems such as inversion error, complexity, and differential absorption laser radar inversion of target gas concentration errors, etc., to reduce inversion Error, the effect of improving data reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

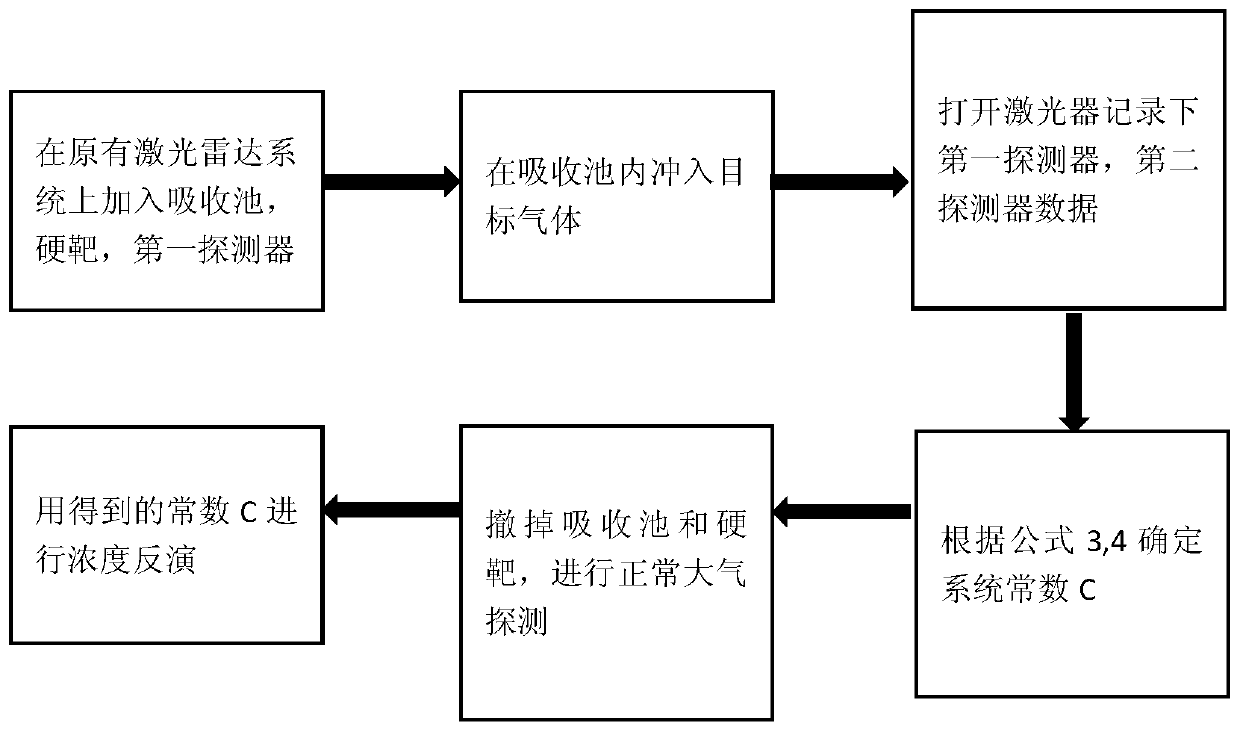

[0022] The present invention will be described in further detail below in conjunction with the accompanying drawings.

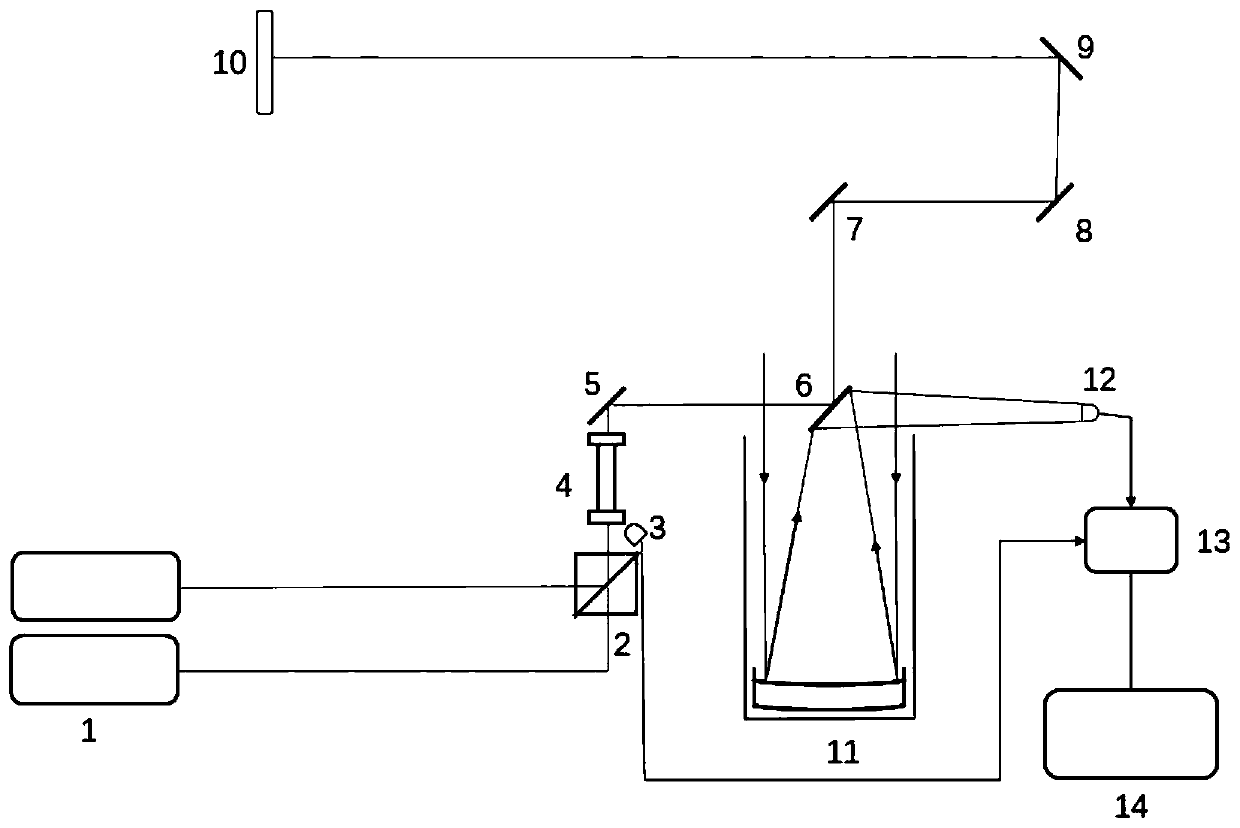

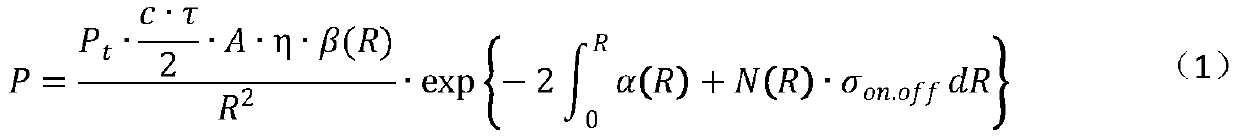

[0023] The present invention takes a set of general differential absorption laser radar system as an example, the laser radar system mainly includes a laser radar transmitting system, a laser radar receiving system and a main control system; wherein, the laser radar transmitting system includes a laser 1, a beam combiner 2, a One 45° full mirror 5, the second 45° full mirror 6, the third 45° full mirror 7, the fourth 45° full mirror 8, the fifth 45° full mirror 9, and the third 45° full mirror Reflective mirror 7, the fourth 45 ° full reflective mirror 8, the fifth 45 ° full reflective mirror 9 constitute a three-dimensional turntable and hard target 10; the lidar receiving system includes a cow anti telescope 11, the first photodetector 3, the second Photodetector 12 and signal acquisition card 13; Main control system uses industrial computer 14 to be connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com