Whole-process visible anti-void forward top reaching construction method for tunnel vault concrete

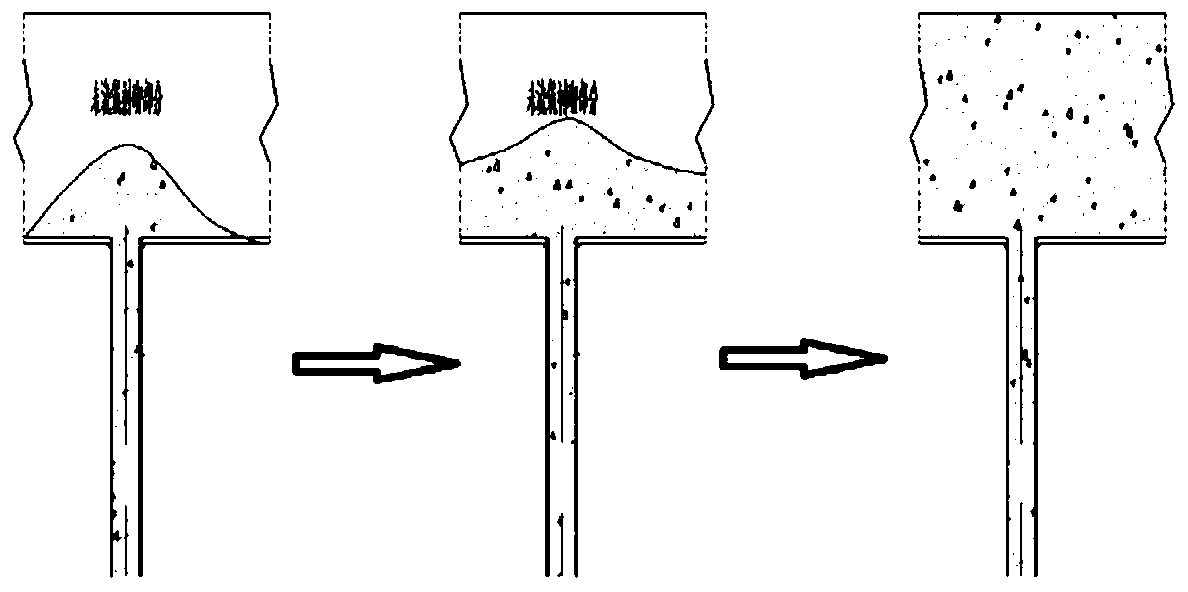

A construction method and concrete technology, applied in tunnels, tunnel linings, earthwork drilling, etc., can solve the problems of unfilled full linings and voids, and achieve the effect of avoiding voids in vault concrete

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] Below by embodiment and in conjunction with accompanying drawing, the present invention will be further described:

[0039] A fully visualized forward-push construction method for concrete void-proofing of a tunnel vault, comprising the following steps:

[0040] Step 1: Use the lining trolley to arrange several pouring holes at intervals along the length direction of the tunnel vault, and each pouring hole is equipped with an anti-vacation positive punching device.

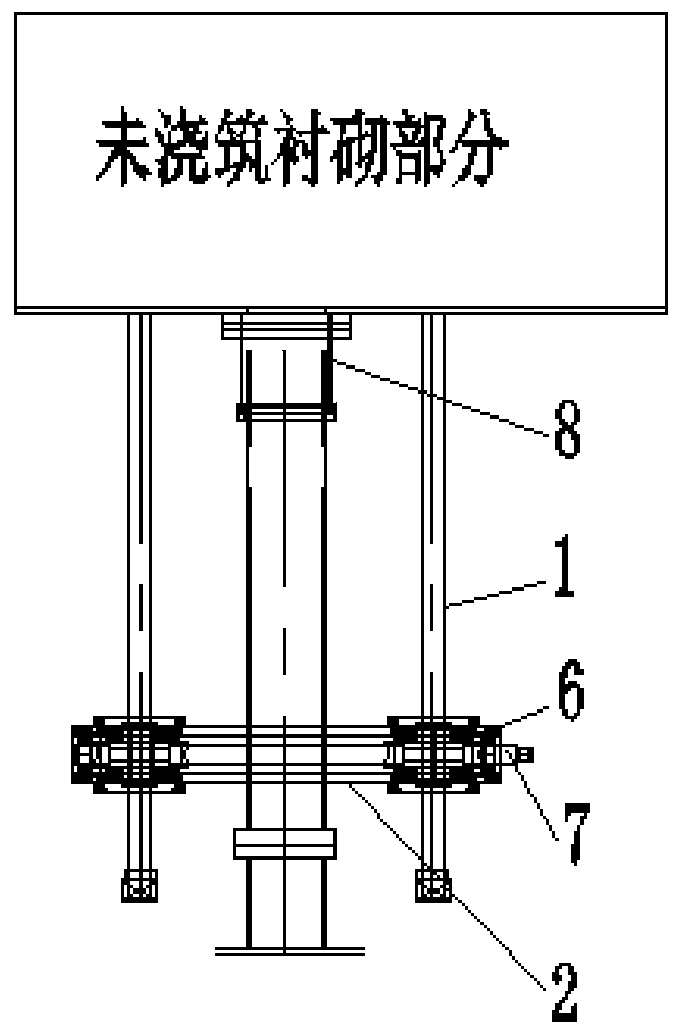

[0041] combine image 3 — Figure 5 As shown, the anti-vacation forward punching device is mainly composed of a fixed vertical rod 1, a lifting seat 2, a closed gate valve 3 and a conduit 4. The conduit 4 is fixedly installed above the lifting seat 2, and is used for connecting the concrete delivery pump pipe. The closed gate valve 3 is installed on the upper end of the fixed vertical rod 1, and the opening and closing of the closed gate valve 3 is automatically controlled by a horizontal cylinder 5 or a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com