Mounting precision control method for stern door hinges

A control method and installation accuracy technology, which is applied in the field of stern door hinge installation accuracy control, can solve the problems that the dummy shaft cannot be disassembled and the stern door hinge is enlarged, so as to facilitate the removal of the dummy shaft, avoid the accumulation of errors, and ensure the correctness of installation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0042] Such as Figure 1-Figure 11 A method for controlling the installation accuracy of a stern door hinge is shown, including the following steps:

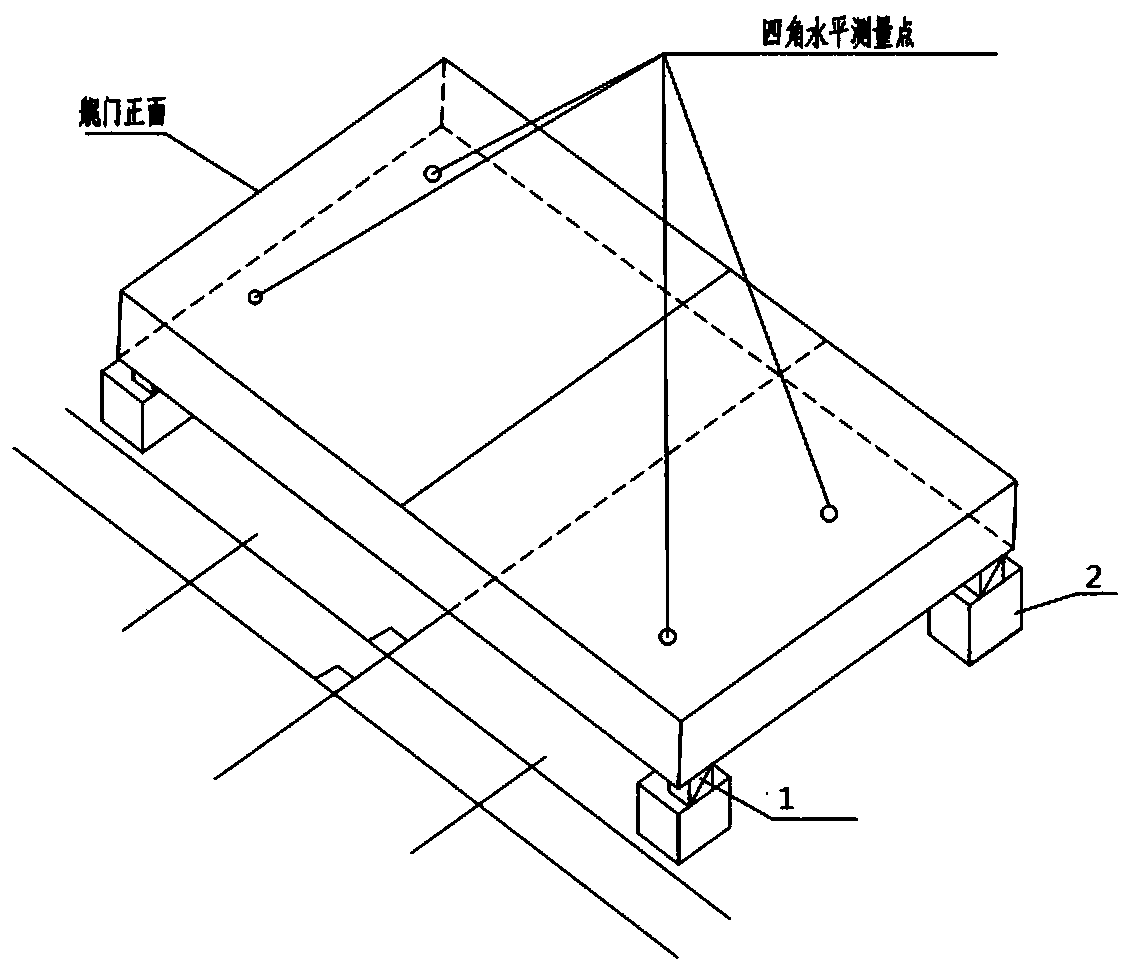

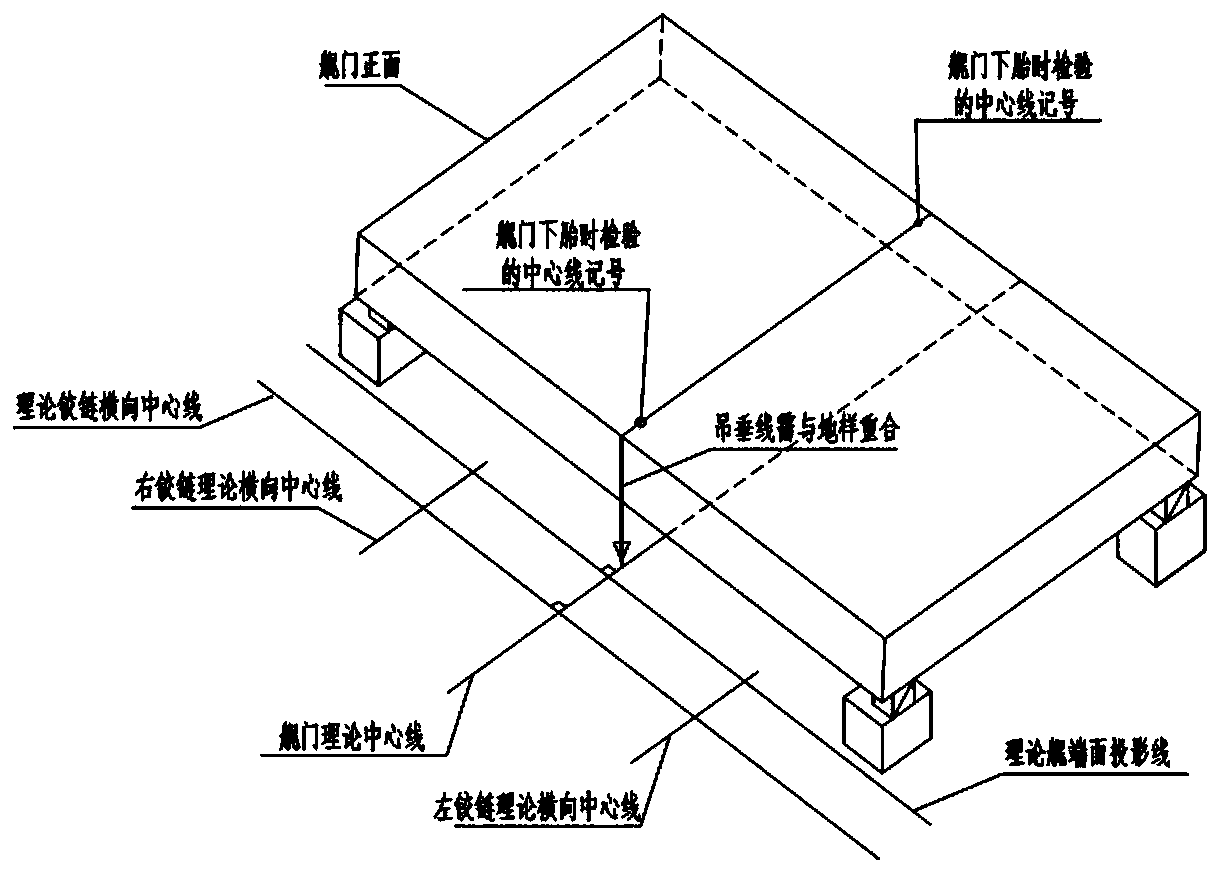

[0043] A. Preparatory work before installation: ① Use the method of hanging vertical line projection to describe the inspection center line of the stern door before the tire frame; ② Eliminate the welding stress during the production of the stern door body after the bodiless frame; work correction;

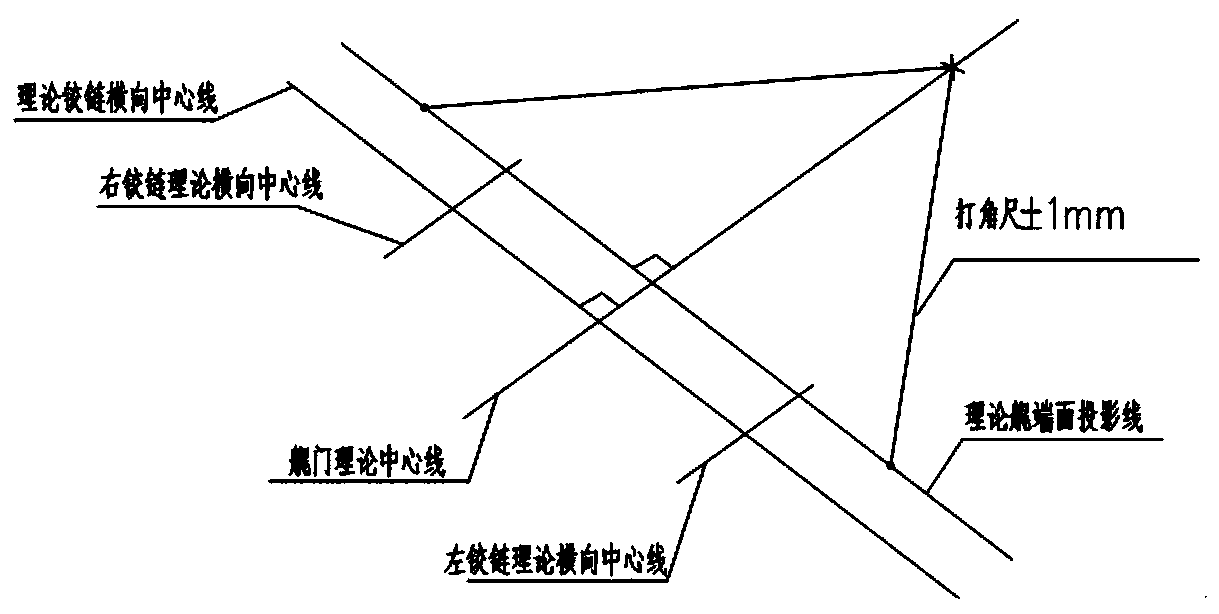

[0044]B. According to the theoretical data of the drawing, draw the reference line of the ground sample on the horizontal ground: the reference line includes the theoretical center line of the stern door and the longitudinal theoretical center line of the hinge. The longitudinal theoretical center line of the hinge is required to be perpendicular to the theoretical center line of the stern door. , the trans...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com