Melt spinning device

A melt-spinning and guiding device technology, which is applied in transportation and packaging, textiles and papermaking, and thin material processing, and can solve problems such as the impossibility of stable positioning and directional guidance of yarns

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

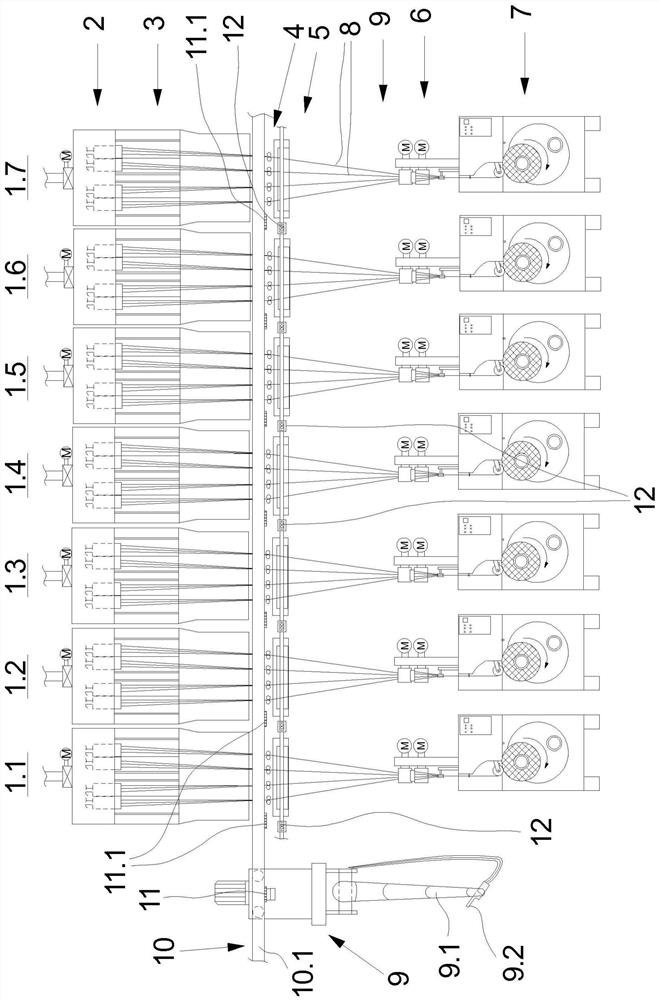

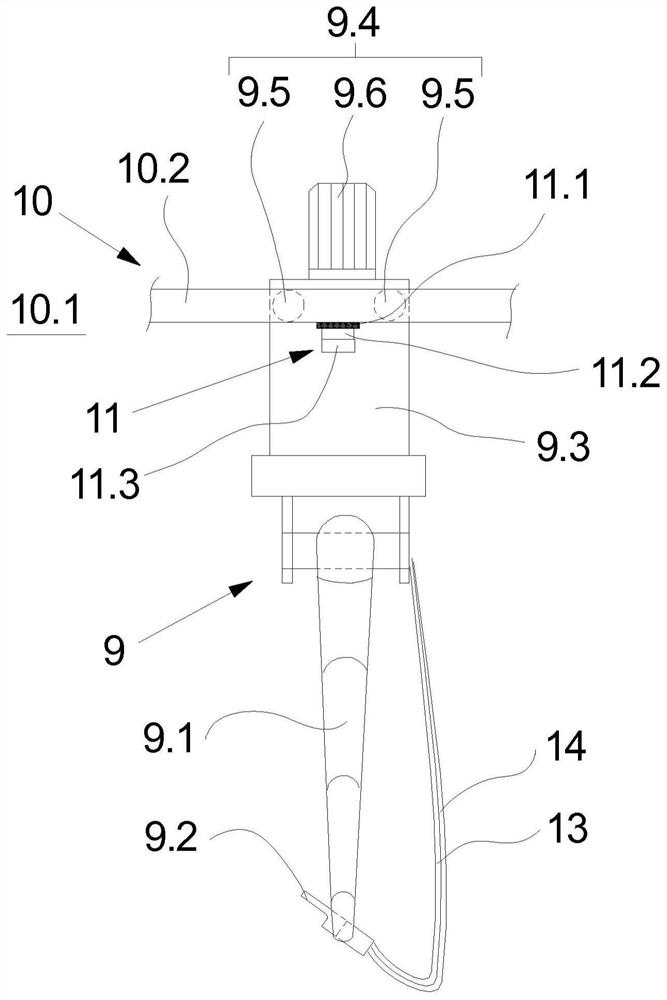

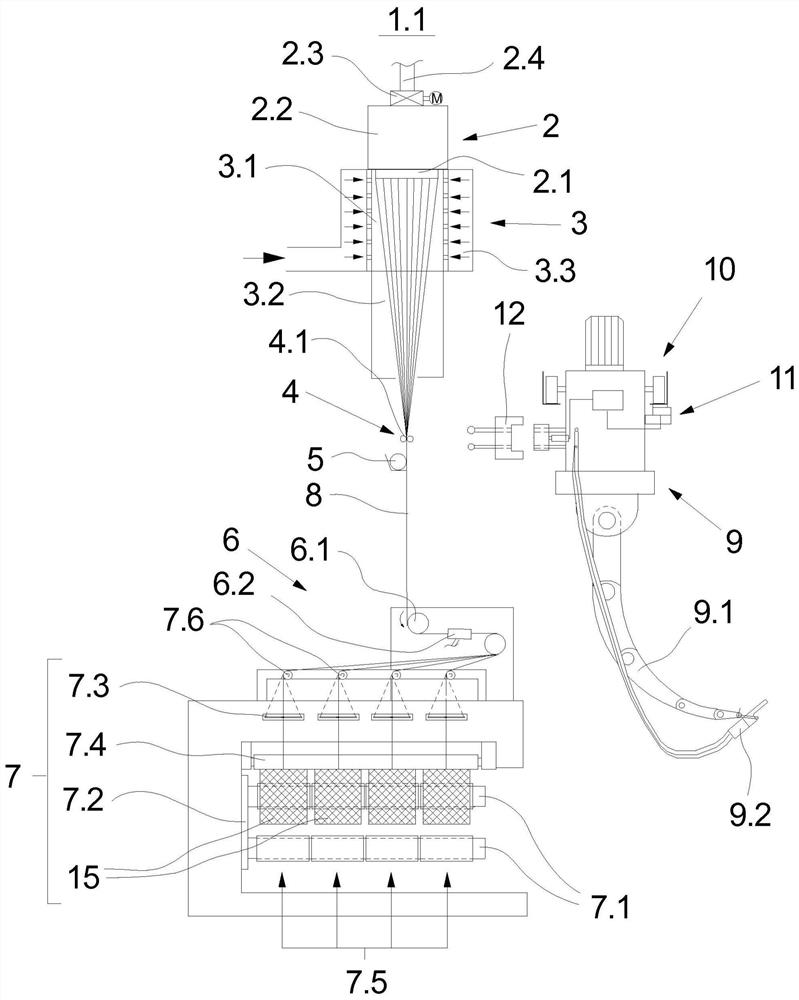

[0024] An embodiment of the melt-spinning device of the invention with a plurality of spinning positions is in figure 1 and image 3 The front view and side view are shown. The following descriptions apply to both figures unless one of them is explicitly mentioned.

[0025] An embodiment of the melt-spinning device according to the invention has a plurality of spinning positions 1.1-1.7, which are arranged next to each other in a row and form machine longitudinal sides. like figure 1 The number of spinning positions shown is exemplary only. In principle, such a melt spinning unit contains several spinning positions of the same type.

[0026] like figure 1 and image 3 The spinning positions 1.1-1.7 shown are designed identically in terms of their structure. The following will be as image 3 The spinning position 1.1 shown in the side view is taken as an example to describe these devices in more detail.

[0027] Each spinning position 1.1-1.7 has a spinning nozzle arra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com